-Taper Cut Wire Saw/Diamond Wire Saw

Table of Contents

Taper Cutting Machine SVT60-50 Brief Description

A “taper cutting machine” generally refers to a machine or equipment capable of performing taper cuts. Taper cuts involve cutting material at an angle, resulting in a sloped or tapered edge. These machines are commonly used in various industries for precision cutting applications where the cut needs to have a gradual incline or taper. The specific design and functionality may vary based on the industry and application requirements.

SVT60-50 is a diamond wire cutting machine that utilizes a closed-loop diamond wire as a cutting tool. It is capable of cutting any material softer than diamond, including both conductive and non-conductive materials.

In addition to cutting cones, it can also cut square tapers and various other two-dimensional profiles. Combining multiple functions in one, it offers simple operation, and its cutting speed is 4 to 6 times faster than traditional wire cutting devices.

Taper Cutting Machine Client On-site Video

@shinediamondwireloop Cut the taper first then cut the trenching

♬ 原聲 – Shine Wire Cut – Shine Wire Cut

Unique advantages of this taper cutting machine

1,Exceptional Sharpness:

The use of diamond as the cutting tool, combined with the high wire speed, ensures that the machine is exceptionally sharp.

2,Superior Surface Quality:

The continuous motion of the endless diamond wire and the precision of its unidirectional movement result in a consistently smooth cutting action. This meticulous control leads to superior cut surface quality.

3,Low Dust Emissions:

Unlike traditional cutting methods that generate more dust, our graphite cutting machine produces minimal dust.

4,High Precision:

The unidirectional motion of the endless diamond wire ensures precise cuts with minimal deviation. This high level of precision is a result of the machine’s advanced technology and engineering.

5,Easy to Operate:

No need for the traditional reciprocating work of winding and tensioning in diamond wire cutting devices. The circular diamond wire is directly placed on the pulley. The programming is also very simple.

Comparison of different machines which processing taper

here’s a comparing table about the advantages and disadvantages of various devices capable of cutting cones:

| Features/Devices | Endless Diamond Wire Cut Machine | Wire EDM Machine | CNC Lathe | CNC Milling Machine | CNC Cutting Machine |

|---|---|---|---|---|---|

| Material Types for Cutting | Various materials | Conductive materials | Various materials | Various materials | Various materials |

| Conductivity Requirement | Not restricted | Requires conductivity | Not restricted | Not restricted | Not restricted |

| Cutting Speed | High | Low | Medium to High | Medium to High | Medium to High |

| Suitable for Complex Shapes | Yes | Yes | Yes | Yes | Yes |

| Precision | High | High | High | High | Medium to High |

| Processing Efficiency | High | Low | Medium to High | Medium to High | Medium to High |

| Cutting Heat Impact | Low | High | Low | Medium | Medium |

| Processing Cost | Medium | High | Medium to High | Medium to High | Medium to High |

| Material Limitations | None | Requires conductivity | None | None | None |

| Applicable Industries | Manufacturing, Construction, etc. | Mold making, Metalworking | General machining | General machining | Cutting, Metal working |

Please note that the suitability of each device depends on specific application scenarios and processing requirements. For instance, while the Endless Diamond Wire Cut Machine is versatile with various materials, the Wire EDM Machine might be more suitable for applications demanding higher precision. The choice of the most suitable device should consider factors such as material, shape, precision, speed, and cost.

Get In Touch

Taper Cutting Machine Product Detail

Typical specifications for this Taper Cutting Machine:

| Machine Spec | ||

| Number | Parameter | Value or Specification |

| 1 | Maximum Workpiece Length (mm) | 600 |

| 2 | Maximum Workpiece Width (mm) | 600 |

| 3 | Maximum Workpiece Height (mm) | 500 |

| 4 | Worktable Y-Axis Travel (mm) | 600 |

| 5 | Worktable Z-Axis Travel (mm) | 600 |

| 6 | Maximum Diamond Wire Speed (m/s) | 84 (Max) |

| 7 | Minimum Feed Increment Y-Axis (mm) | 0.01 |

| 8 | Minimum Feed Increment Z-Axis (mm) | 0.01 |

| 9 | Repeat Positioning Accuracy Y-Axis (mm) | ±0.02 |

| 10 | Repeat Positioning Accuracy Z-Axis (mm) | ±0.02 |

| 11 | Total Power Consumption (kW) | 7.5 |

| 12 | Power Supply | AC380V 50Hz |

| 13 | Machine Size(mm) | 2200*2000*1900 |

| 14 | Machine Weight(kg) | 2000 |

Other Models with Same Structure

there are machine of different size and additional functio to cut different material size and type.

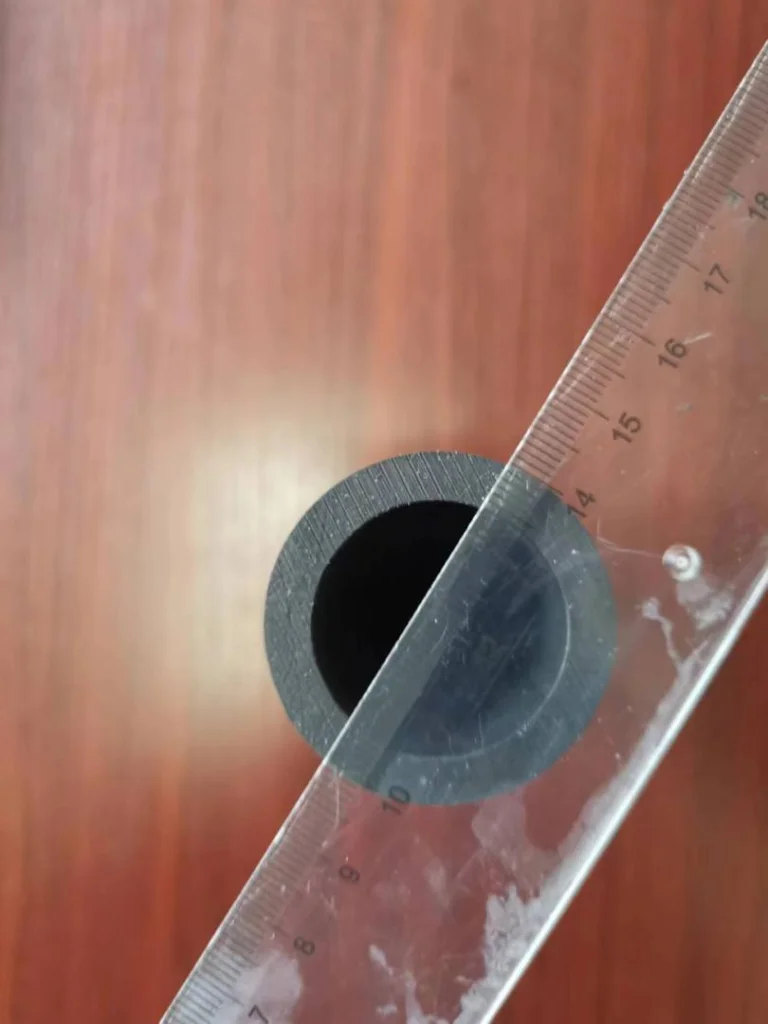

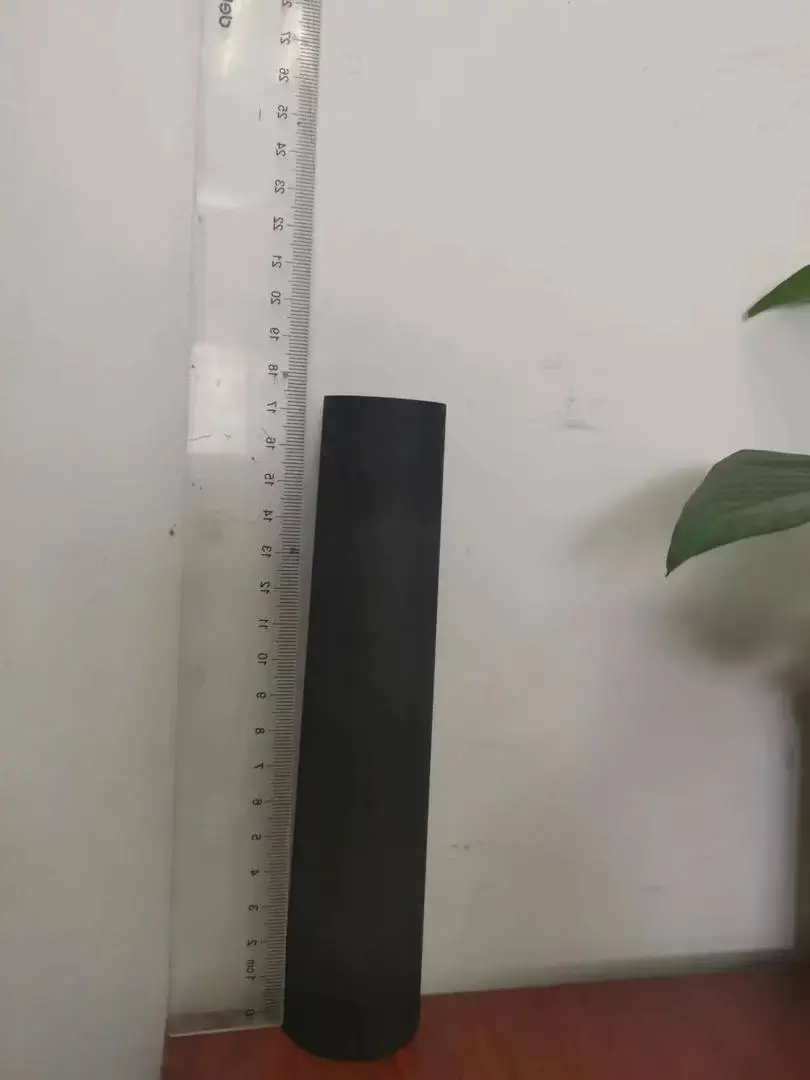

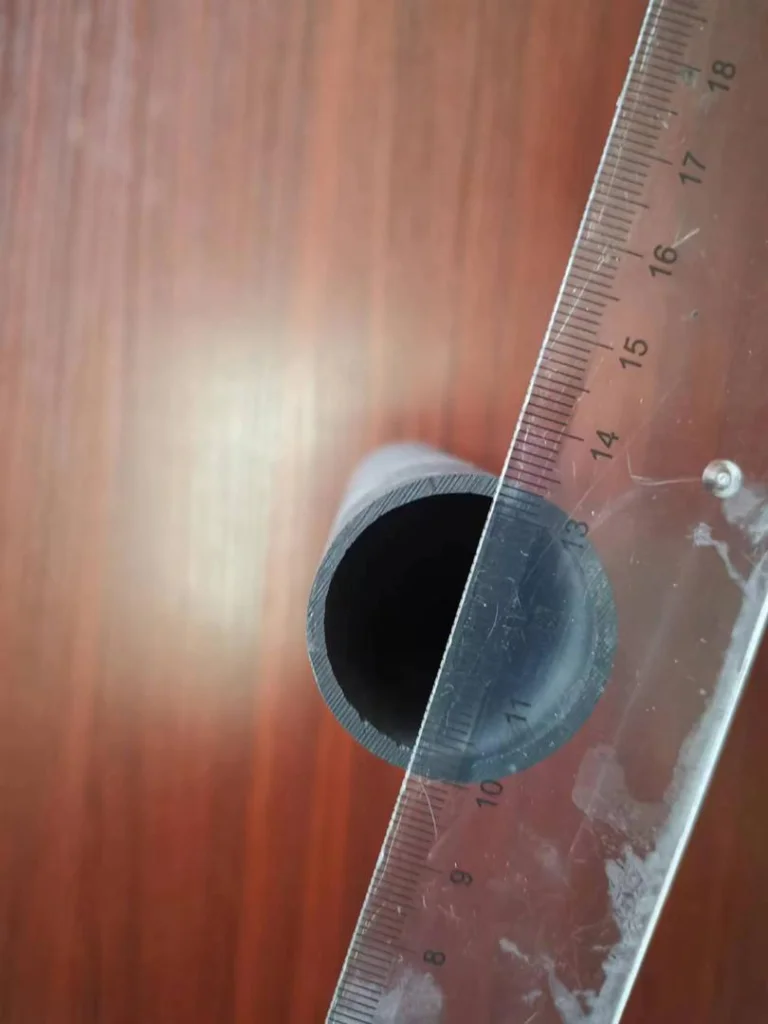

Pictures of successful case of our Graphite Cut Wire Saw

Support and Services

Maintenance and Servicing:

We provide comprehensive maintenance and servicing services to ensure the long-term reliable operation of the silicon rod cutting equipment. Our dedicated maintenance team possesses extensive experience and technical knowledge to promptly respond to and resolve equipment issues. We made check list to conduct regular preventive maintenance, inspecting and adjusting critical components to ensure optimal performance and accuracy. Whether it’s routine maintenance or emergency repairs, we are committed to delivering fast and efficient servicing to minimize equipment downtime.

And we have local service available in Canada.

Training:

We offer comprehensive training programs designed to empower customers with in-depth knowledge and proficiency in operating and maintaining the silicon ingot cutting machine. Our training courses cover basic equipment operation, safe usage practices, maintenance procedures, and troubleshooting. Customized training content and flexible training methods, including on-site training, remote training, and provision of training materials, are provided based on customer needs and backgrounds. Through our training programs, customers can enhance their operational skills, improve equipment efficiency, and ensure long-term reliable performance.

Consulting:

We provide professional consulting services to meet customer needs regarding silicon ingot cutting machine and related areas. Our team of experts offers tailored advice and solutions based on specific requirements. Whether it’s equipment selection, process optimization, production line layout, or quality control, we collaborate with customers, providing professional guidance and technical support. We strive to establish long-term partnerships with customers, working together to address various technical and engineering challenges, meet their needs, and achieve mutual success.

Perfectly Solve Your Cutting Problems

Vertical wirecutting machine can be adapted to all cutting scene with an satisfying performance

We accept sample cutting service, leave your information and enjoy our free cutting test service →

-1536x1024.jpg)

-1-1536x886.jpg)

.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1-1536x861.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1536x1024.jpg)