An automatic wire saw is a practical machine for slicing one-of-a-kind materials like stone, steel, and concrete. Unlike manual saws, wire saw cutting machines are used in the advanced era to make cutting faster, less complicated, and more particular. They are extensively used in industries that frequently need to cut huge or complex substances. This text discusses the benefits of using an automated wire saw and how it benefits specific industries.

Key Advantages of Using an Automatic Wire Saw

1. Faster Cutting Speed

One of the biggest blessings of an automated wire saw is its speed. It cuts materials an awful lot quicker than traditional guide saws. The machine can hold a consistent velocity during the procedure with automatic controls. This reduces the cutting time, making it ideal for industries that want to paint on significant initiatives. Faster cutting speeds cause higher productivity, which is crucial in construction, mining, and manufacturing.

2. Precision and Accuracy

Another foremost advantage of using an automatic wire saw is its precision. The gadget is designed to make clean, accurate cuts. Whether operating with stone, metal, or glass, precision wire sawing guarantees that the cuts are clean and specific; this is mainly beneficial in industries like construction and sculpture, in which the pleasantness of the reduction is crucial. Precision cuts additionally assist in lessening fabric waste, saving time and money in the long run.

3. Easy to Use

Automatic wire saws are consumer-pleasant. They are designed to perform with minimum effort. Once the settings are adjusted, the machine does the relaxation. This ease of use makes them available to people with exceptional talent degrees. You don’t want to be an expert to apply an automated wire saw. With the proper schooling, each person can operate it. This additionally reduces the chance of errors or accidents, making it a more secure choice for employees.

4. Versatile for Different Materials

Automatic wire saws are exceptionally flexible. They can cut through various materials, including stone, metal, concrete, and glass, making them useful in numerous industries. For example, in the production enterprise, they are used to cut massive blocks of stone and urban. In the mining enterprise, they are used to cut rugged rocks. Their capacity to handle exceptional materials makes diamond wire saws essential for many sectors.

5. Lower Labor Costs

Since an automatic wire saw operates with minimum human intervention, it facilitates reduced complex work expenses. Workers do now not need to spend hours manually cutting substances. Instead, they can be aware of other vital responsibilities while the machine does the cutting. This additional method, in which fewer workers want to complete the process, is mainly meant to price financial savings for companies. Blended with faster-slicing instances, lower exertion fees help growth average performance.

6. Reduced Material Waste

Precision slicing no longer ensures accuracy but also reduces material waste. Conventional saws usually produce a lot of garbage because of choppy cuts. However, CNC wire saws make easy cuts, minimizing the amount of material wasted. This is particularly useful when working with expensive materials like marble or granite. Reducing waste approaches saving cash, which is usually a plus for organizations.

7. Improved Safety

Safety is a significant concern in industries containing heavy or harsh substances. Traditional cutting methods may be dangerous, specifically when workers need to deal with the substances manually. Automatic wire saws reduce this chance. Since the machine does most of the work, employees do not want to be as near the fabric being cut, lowering the chances of accidents. Many Industrial wire saws also come with protection functions that forestall the gadget and shield the operators if there’s an issue.

What is the best automatic wire saw machine, and where can you buy it?

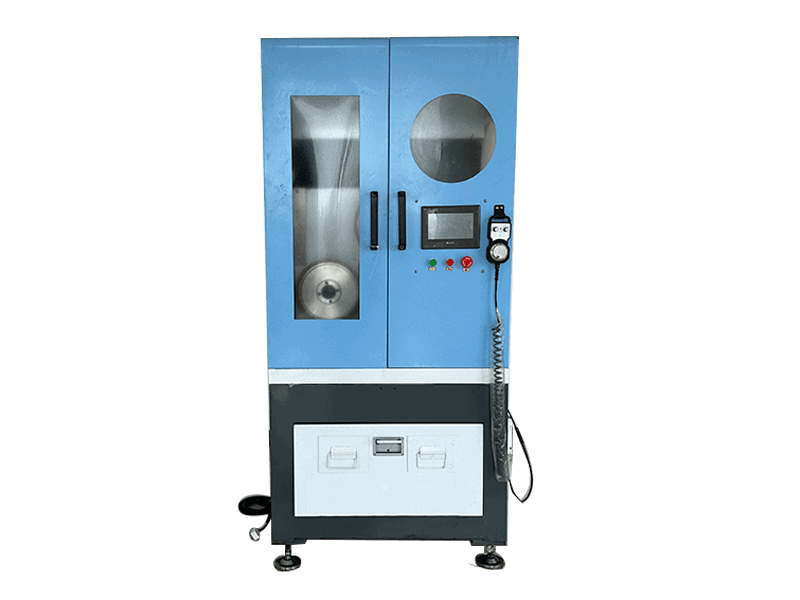

The SGR 40 is an excellent automated cutting saw machine in the marketplace. This system stands proud due to its speed, precision, and ease of use. Whether you need to reduce stone, metallic, or concrete, the SGR 40 can handle it. Its automated controls ensure smooth and accurate cuts every time, making it a dependable preference for many industries.

One of the significant benefits of the SGR 40 is its capability to reduce significant substances quickly. This feature saves time and enables improved productivity. Its user-friendly layout makes it easy to use, even for people with less experience. In this approach, you don’t need to be an expert to get the best results.

If you want an excellent automatic wire saw system, the best dealer is Shine. Known for supplying remarkable gadgets, Shine offers long-lasting and efficient machines. They are a relied-on call in the industry, making them an exceptional area to buy the SGR 40.

FAQs

What materials can an automatic wire saw reduce?

An automatic wire saw can reduce many substances, including stone, metallic, concrete, glass, and ceramics. Its versatility makes it beneficial in many industries.

Is it tough to operate an automated wire saw?

No, automated wire saws are designed to be smooth to apply. With proper schooling, people of different ability levels can function competently and effectively in the machine.

Does an automatic wire saw reduce waste?

Yes, the precision of an automatic wire saw reduces cloth waste by making clean and correct cuts. This is particularly useful when working with highly-priced substances.

In Wrapping Up

An automatic wire saw offers many blessings, from quicker slicing speeds to advanced safety and decreased exertion prices. It is a flexible machine that can manage the spread of substances, making it treasured in industries like creation, mining, and manufacturing. The machine’s capability to deliver specific, constant cuts reduces cloth waste and saves time. While the initial cost of buying a wire saw blade technology may be high, the long-term blessings, consisting of lower exertion charges and accelerated performance, make it clever funding for groups.