Table of Contents

Circular Diamond wire cutting, a technique that utilizes circular diamond-infused wires to slice through various materials, has gained significant attention in recent years due to its remarkable efficiency and cost-effectiveness. This method, often referred to as “diamond wire sawing,” has revolutionized industries like construction, mining, and manufacturing by offering unparalleled economic benefits and cost advantages. In this article, we will explore how diamond wire cutting has transformed these industries and examine its key benefits in terms of both economic efficiency and cost-effectiveness.

Introduction to Circular Diamond Wire Cutting

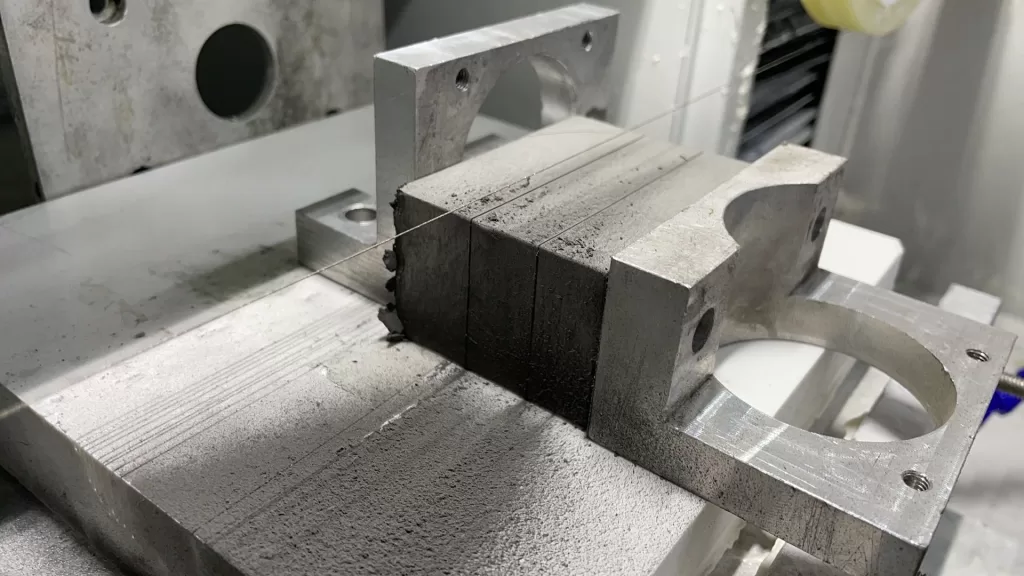

Circular diamond wire cutting involves the use of a high-strength wire embedded with diamond beads, which act as the cutting agents. The wire is continuously looped around a set of pulleys, creating a cutting path. As the wire passes through the material to be cut, the diamond beads abrade the material’s surface, resulting in a precise and efficient cutting process. This technique is commonly employed to cut through hard and abrasive materials, such as stone, ceramics, graphite, and even metals.

Economic Benefits of Circular Diamond Wire Cutting

1. Increased Productivity

Circular diamond wire cutting significantly enhances productivity compared to traditional cutting methods. The continuous nature of the cutting process eliminates the need for frequent tool changes, reducing downtime and allowing for uninterrupted cutting. This efficiency boost translates into faster project completion times and increased throughput, which is particularly crucial in industries where time-sensitive operations are involved.

2. Precision and Reduced Material Loss

The precision offered by circular diamond wire cutting is unparalleled. The fine diameter of the wire and the abrasive action of the diamond beads result in minimal material loss during the cutting process. This precision not only reduces waste but also enables intricate cuts and shapes that would be difficult or impossible to achieve with conventional methods. As a result, industries can maximize the utility of raw materials and reduce the overall cost per unit of material processed.

3. Versatility

Diamond wire cutting’s versatility extends across a wide range of materials, from natural stone to reinforced concrete. This adaptability minimizes the need for specialized equipment for each material type, leading to substantial cost savings. The ability to cut through diverse materials using a single technique simplifies operations and reduces equipment maintenance and training requirements.

Cost Advantages of Circular Diamond Wire Cutting

1. Reduced Labor Costs

The automation inherent in diamond wire cutting systems reduces the need for extensive manual labor. Operators oversee the process, but the continuous cutting eliminates the physical effort required by traditional methods. This reduction in labor requirements not only cuts down on wages but also improves workplace safety by minimizing worker exposure to potentially hazardous cutting processes.

2. Lower Maintenance Costs

Diamond wire cutting machines are designed for durability and require less frequent maintenance compared to conventional cutting tools. The cutting wire itself has a longer lifespan than many traditional cutting blades, reducing replacement costs. Additionally, the reduced wear and tear on the machinery result in longer intervals between maintenance cycles, further contributing to cost savings.

3. Efficient Resource Utilization

The precision of circular diamond wire cutting minimizes material waste, which is especially significant when working with expensive or rare materials. This efficient utilization of resources directly translates to cost savings by maximizing the yield from each raw material unit. Moreover, the reduced energy consumption of diamond wire cutting systems compared to some other cutting methods contributes to lower operational costs.

Conclusion

Circular diamond wire cutting has emerged as a transformative technology with remarkable economic benefits and cost advantages across various industries. Its ability to enhance productivity, provide precision cuts with minimal material loss, and offer versatile applications positions it as a powerful tool for modern manufacturing, mining, and construction practices. With reduced labor and maintenance costs, efficient resource utilization, and a broad material range, diamond wire cutting stands as a testament to innovation driving economic efficiency and sustainability in industry operations. As technology continues to advance, we can anticipate even more widespread adoption of circular diamond wire cutting, further revolutionizing how we approach cutting and shaping materials.