In the realm of high-performance manufacturing, achieving precision in machining components is crucial. One of the most effective methods for machining industrial ceramics is through wire sawing. This article delves into the techniques, benefits, and applications of wire sawing in the machining of industrial ceramics, focusing on achieving high precision and performance in various components. From its technological intricacies to its industrial applications, let’s explore how wire sawing is transforming the landscape of precision machining.

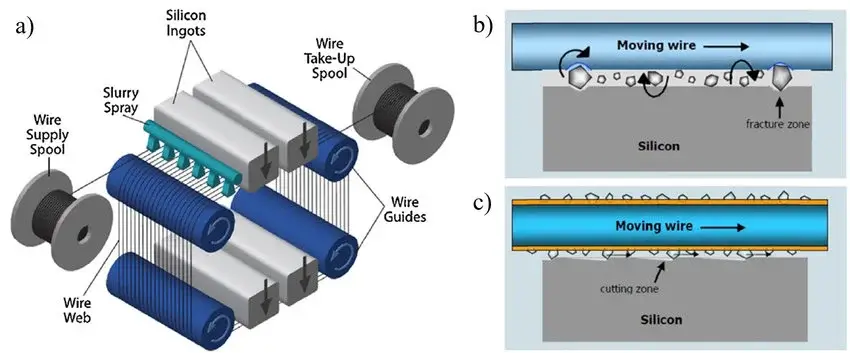

Wire sawing technology has revolutionized the machining of industrial ceramics. This technique involves using a thin wire, often coated with diamond particles, to cut through ceramic materials with remarkable accuracy. The importance of wire sawing in the machining of industrial ceramics cannot be overstated. It plays a pivotal role in achieving high-precision cuts, which are essential for components used in critical applications such as electronics, aerospace, and medical devices. The precision offered by wire sawing ensures that the final products meet stringent quality standards, making it an indispensable tool in modern manufacturing.

Wire sawing offers numerous advantages when it comes to machining industrial ceramics. Here are some key benefits:

- Reduzierter Materialabfall: The thin wire used in wire sawing minimizes kerf loss, leading to less material waste.

- Enhanced Accuracy: Wire sawing allows for precise cuts, ensuring that components meet exact specifications.

- Improved Surface Quality: The smooth cutting action of the wire results in superior surface finishes, reducing the need for additional finishing processes.

These advantages make wire sawing an ideal choice for manufacturers looking to optimize their production processes while maintaining high standards of quality.

Various types of wire saws are employed in the machining of ceramics, each with unique features suited to different applications. Some common types include:

- Wire Cutting Machine: These machines use a continuous loop of wire for cutting, providing consistent performance and high precision.

- Diamond Wire Cutting Machine: Equipped with diamond-coated wires, these machines offer superior cutting capabilities, especially for hard ceramic materials.

- Diamond Wire Machine: Similar to diamond wire cutting machines, these are designed for heavy-duty cutting tasks and can handle large ceramic components.

Choosing the right type of wire saw depends on the specific requirements of the machining process, including the material properties and desired precision.

The efficiency and longevity of wire saws are significantly influenced by the materials and coatings used in their manufacturing. Common materials include high-strength alloys and stainless steel, which provide durability and resistance to wear. Additionally, coatings such as diamond particles enhance the cutting performance of the wire. These coatings not only improve the wire’s ability to cut through tough ceramic materials but also extend its lifespan, reducing the frequency of replacements and maintenance.

Wire sawing of ceramics finds applications across various industries due to its precision and efficiency. Some notable applications include:

- Electronics: Precision cutting of ceramic substrates for semiconductors and electronic components.

- Luft- und Raumfahrt: Machining of high-performance ceramic components used in aircraft and spacecraft systems.

- Medizinische Geräte: Production of ceramic parts for medical implants and diagnostic equipment.

The versatility of wire sawing makes it an essential technique in industries where precision and performance are paramount.

Despite its advantages, wire sawing of ceramics presents several challenges. These include:

- Werkzeugverschleiß: The abrasive nature of ceramics can lead to rapid wear of the wire, necessitating frequent replacements.

- Schneidgeschwindigkeit: Achieving the right balance between cutting speed and precision can be challenging, especially for complex shapes.

- Thermal Management: The cutting process generates heat, which must be managed to prevent damage to the ceramic material.

Addressing these challenges requires a combination of advanced materials, optimized cutting parameters, and efficient cooling systems.

As technology continues to advance, the field of ceramics wire sawing is expected to see several exciting trends. These include:

- Enhanced Wire Materials: Development of new materials and coatings that offer even greater durability and cutting efficiency.

- Automatisierung: Integration of automated systems for precise control and monitoring of the sawing process.

- Environmental Sustainability: Innovations aimed at reducing the environmental impact of the sawing process, such as recycling of cutting fluids and minimizing waste.

These trends are set to shape the future of precision machining, enabling manufacturers to achieve higher levels of performance and efficiency in their operations.

In conclusion, Industrial Ceramics Wire Sawing is a game-changer in the world of precision machining. With its ability to deliver high-precision cuts and superior surface quality, it is an invaluable tool for industries ranging from electronics to aerospace. As technology continues to evolve, the future of wire sawing looks brighter than ever, promising even greater advancements in the machining of high-performance ceramic components.

Introduction to Wire Sawing Technology

In the world of precision machining, Industrial Ceramics Wire Sawing stands out as a groundbreaking technology. This cutting-edge technique is pivotal in the machining of industrial ceramics, allowing for incredibly precise cuts that are essential for high-performance components. But what exactly is wire sawing, and why is it so important? Let’s dive in.

Wire sawing technology revolves around the use of a thin wire, often embedded with diamond particles, to cut through hard materials like ceramics. This method is akin to using a fine-toothed saw, but with a wire that slices through the material with unparalleled precision. The wire, which is continuously looped, moves at high speeds, ensuring a clean and accurate cut. Companies like Shine have perfected this technology, making it a go-to for industries that require meticulous machining.

One of the standout features of Industrial Ceramics Wire Sawing is its ability to produce high-precision cuts with minimal material waste. Unlike traditional cutting methods, which can be rough and imprecise, wire sawing offers a level of accuracy that is essential for components used in high-stakes environments. This makes it an invaluable tool in sectors like electronics, aerospace, and medical devices, where even the smallest error can have significant consequences.

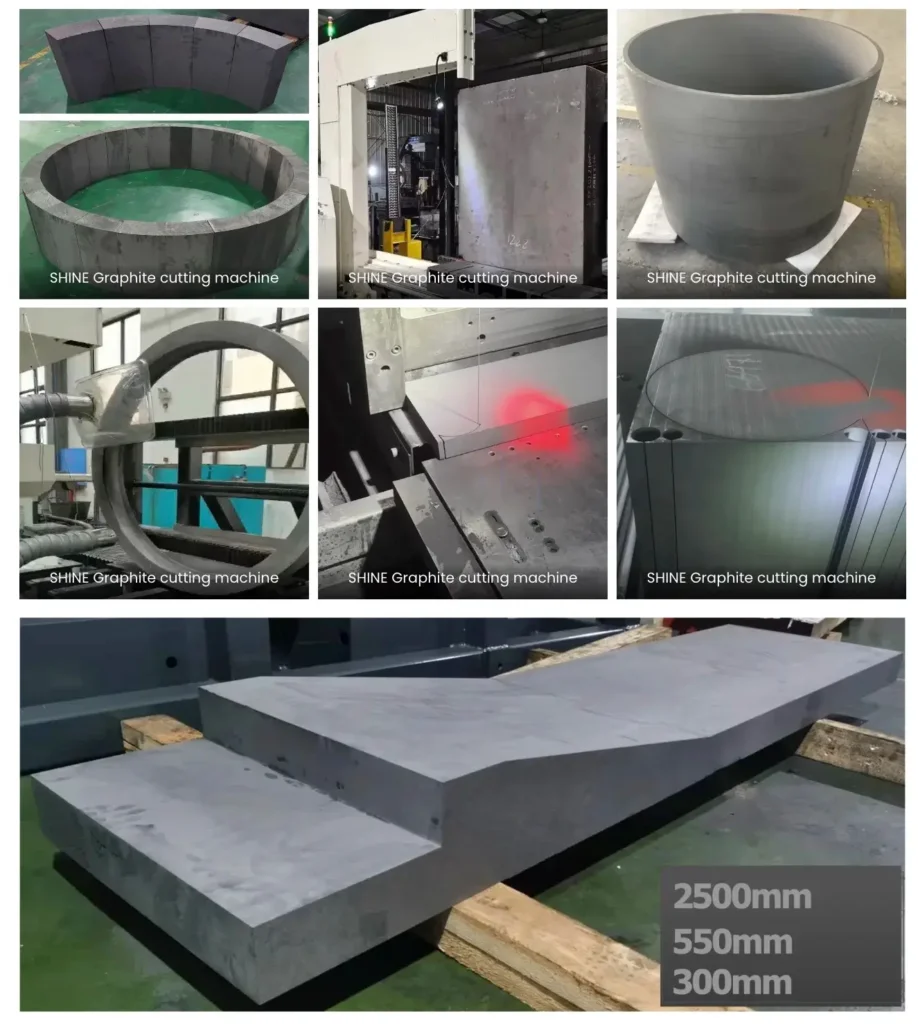

The technology behind wire sawing is continually evolving. Modern wire cutting machines, including the diamond wire cutting machine and diamond wire machine, have brought about significant advancements in the field. These machines are designed to handle the toughest materials, ensuring that the wire sawing process is not only efficient but also durable. Shine, a leader in this space, has developed machines that push the boundaries of what is possible, setting new standards for precision and performance.

In summary, Industrial Ceramics Wire Sawing is a revolutionary technology that has transformed the way we machine ceramics. With its high precision, reduced material waste, and continuous advancements, it is no wonder that industries across the globe are turning to wire sawing for their most critical components. As we continue to innovate and refine this technology, the future of precision machining looks brighter than ever.

Advantages of Wire Sawing in Ceramics

When it comes to machining industrial ceramics, wire sawing technology stands out as a game-changer. This technique, known as Industrial Ceramics Wire Sawing, offers a plethora of advantages that cater to the high precision and performance demands of modern industries. Let’s delve into why wire sawing, particularly with brands like Shine, is the go-to method for cutting ceramics.

First and foremost, wire sawing dramatically reduces material waste. Traditional cutting methods often result in significant material loss, but with wire sawing, the kerf (the width of the cut) is minimal. This means more of the valuable ceramic material is preserved, leading to cost savings and efficient resource utilization. Shine’s wire sawing solutions are especially designed to maximize material retention, making them a preferred choice in the industry.

Ein weiterer wesentlicher Vorteil ist die enhanced accuracy offered by Industrial Ceramics Wire Sawing. The precision of wire saws ensures that cuts are made exactly where needed, with tolerances often reaching micrometer levels. This level of precision is crucial in industries where even the slightest deviation can lead to product failure. Shine’s wire cutting machines are engineered to deliver this high level of accuracy consistently.

Wire sawing also results in verbesserte Oberflächenqualität. The smoothness of the cut surfaces reduces the need for additional finishing processes, saving both time and money. This is particularly important in applications where the surface integrity of the ceramic component is critical. Shine’s diamond wire cutting machines are known for producing exceptionally smooth cuts, which is a testament to their superior design and engineering.

Let’s not forget the versatility of wire sawing. This technique can be used on a wide range of ceramic materials, from the hardest to the most brittle. Whether you’re working with alumina, zirconia, or silicon carbide, wire sawing can handle it all. Shine’s diamond wire machines are versatile enough to cater to various ceramic types, ensuring that industries have the flexibility they need in their machining processes.

Moreover, the Effizienz of wire sawing cannot be overstated. The process is relatively fast compared to other cutting methods, which translates to higher productivity and shorter lead times. This efficiency is further enhanced by the use of advanced materials and coatings in the wire saws, which we will explore in more detail later. Shine’s wire saws are designed to operate at optimal speeds, ensuring that projects are completed on time without compromising quality.

In summary, the advantages of Industrial Ceramics Wire Sawing are manifold. From reduced material waste and enhanced accuracy to improved surface quality and versatility, this technology is indispensable in the machining of ceramics. Brands like Shine have perfected the art of wire sawing, offering solutions that meet the high standards of modern industries. So, whether you’re in electronics, aerospace, or medical devices, wire sawing is the cutting-edge solution you need.

Types of Wire Saws Used in Ceramics

When it comes to Industrial Ceramics Wire Sawing, selecting the right type of wire saw is crucial for achieving optimal results. Different wire saws come with unique features and are suited for various applications. Let’s dive into the most common types used in ceramics machining.

First up, we have the Diamantdrahtschneidemaschine. This type of saw is renowned for its exceptional precision and efficiency. The diamond wire, embedded with industrial-grade diamonds, ensures that the cutting process is smooth and accurate. This makes it an ideal choice for applications requiring high precision, such as in the electronics and aerospace industries.

Als nächstes haben wir die Drahtschneidemaschine which is versatile and widely used in the ceramics industry. These machines utilize a thin wire to cut through ceramic materials with minimal material waste. The wire cutting machine is particularly useful for intricate cuts and complex shapes, making it a favorite in medical device manufacturing and other high-tech applications.

Another notable type is the diamond wire machine. Similar to the diamond wire cutting machine, this saw uses a diamond-coated wire to slice through ceramics with ease. The key difference lies in its application; the diamond wire machine is often used for larger-scale industrial projects where both speed and precision are paramount.

For a clearer comparison, here’s a quick breakdown of these types:

| Type of Wire Saw | Key Features | Anwendungen |

|---|---|---|

| Diamant-Drahtschneidemaschine | High precision, diamond-coated wire | Electronics, Aerospace |

| Drahtschneidemaschine | Versatile, minimal material waste | Medical devices, Intricate cuts |

| Diamond Wire Machine | Speed and precision, large-scale projects | Industrial applications |

Each of these wire saws has its own set of advantages, and the choice largely depends on the specific requirements of the project. Whether you are in the market for a diamond wire cutting machine or a more general-purpose wire cutting machine, understanding these differences can help you make an informed decision.

At Shine, we specialize in providing top-notch solutions for Industrial Ceramics Wire Sawing. Our range of wire saws is designed to meet the diverse needs of industries, ensuring that you get the best performance and precision in your machining processes.

In conclusion, the type of wire saw you choose can significantly impact the efficiency and quality of your ceramics machining. From the high-precision diamond wire cutting machine to the versatile wire cutting machine, there’s a perfect tool for every application. Make sure to consider your specific needs and consult with experts like Shine to find the ideal solution for your Industrial Ceramics Wire Sawing needs.

Materials and Coatings for Wire Saws

When it comes to Industriekeramik Drahtsägen, the choice of materials and coatings for wire saws is absolutely crucial. The performance, efficiency, and longevity of the wire saw are significantly influenced by these factors. Let’s dive deeper into the materials and coatings that make wire sawing a standout technology in precision machining.

First off, the core material of the wire saw itself is integral to its effectiveness. Common materials used in the manufacturing of wire saws include:

- High-strength steel

- Tungsten

- Molybdenum

These materials are chosen for their durability and ability to withstand the rigors of cutting through tough industrial ceramics. However, the material alone isn’t enough to guarantee success in Industriekeramik Drahtsägen. The coatings applied to these wires play a pivotal role.

One of the most popular coatings used is diamond. Yes, you heard it right—diamonds! Diamond-coated wires are highly effective because of their unparalleled hardness and cutting ability. This is why you’ll often hear terms like Diamant-Drahtschneidemaschine oder diamond wire machine in the industry. The diamond coating ensures that the wire can slice through ceramics with precision and minimal wear.

Other coatings that are frequently used include:

- Nickel

- Electroplated diamond

- Chemical vapor deposition (CVD) diamond

Each of these coatings has its own set of advantages. For example, nickel coatings provide excellent corrosion resistance, which is particularly useful in harsh industrial environments. Electroplated diamond coatings offer a uniform layer of diamond particles, ensuring consistent cutting performance. CVD diamond coatings, on the other hand, provide a thin yet extremely hard layer of diamond, making them perfect for high-precision applications.

So, why is all this important? Well, the right combination of materials and coatings can drastically reduce material waste, enhance accuracy, and improve surface quality. This is especially important in industries like electronics, aerospace, and medical devices, where precision is non-negotiable.

In summary, the materials and coatings used in wire saws are the unsung heroes of Industriekeramik Drahtsägen. They not only determine the efficiency and longevity of the wire saw but also ensure that the cutting process is as precise as possible. Brands like Shine are at the forefront of this technology, continually innovating to provide the best solutions for high-performance components.

Applications of Wire Sawing in Industry

Industrial Ceramics Wire Sawing is a game-changer in numerous industries, thanks to its unparalleled precision and efficiency. This technology, championed by leading brands like Shine, has paved the way for advancements in several high-stakes sectors. Let’s dive into some of the key applications where wire sawing, particularly using wire cutting machines and diamond wire cutting machines, is making a significant impact.

- Elektronik-IndustrieThe electronics industry demands components with extreme precision and fine tolerances. Industrial Ceramics Wire Sawing is crucial in manufacturing intricate parts like semiconductor wafers and microelectronic components. Shine’s advanced diamond wire machines ensure that these components meet the exacting standards required for high-performance electronics.

- Aerospace SectorIn the aerospace industry, every component must withstand extreme conditions and rigorous performance criteria. Wire sawing is employed to create turbine blades, heat shields, and other critical ceramic parts. The precision of Shine’s wire cutting machines ensures that each piece meets stringent aerospace standards, contributing to the overall safety and efficiency of aircraft.

- Medical DevicesMedical devices often incorporate ceramic components due to their biocompatibility and durability. Industrial Ceramics Wire Sawing is used to produce components for implants, surgical instruments, and diagnostic equipment. Shine’s diamond wire cutting machines enable the production of medical-grade ceramics with the highest precision, ensuring reliability and safety in medical applications.

- AutoindustrieHigh-performance ceramics are increasingly used in the automotive industry for components like brake discs, engine parts, and sensors. The precision offered by wire sawing technology is essential for creating these components, which must perform reliably under high stress and temperature conditions. Shine’s wire cutting machines are at the forefront of this innovation, enabling the production of superior automotive ceramics.

- Renewable EnergyAs the renewable energy sector grows, the need for durable and efficient components becomes more critical. Wire sawing is used to manufacture ceramic parts for solar panels, wind turbines, and other renewable energy systems. Shine’s diamond wire machines deliver the precision needed to create components that enhance the efficiency and longevity of renewable energy technologies.

In conclusion, the applications of Industrial Ceramics Wire Sawing are vast and varied. From electronics and aerospace to medical devices and renewable energy, this technology is revolutionizing how high-performance ceramic components are produced. Brands like Shine are leading the charge, providing cutting-edge wire cutting machines and diamond wire machines that ensure the highest levels of precision and efficiency in these critical industries.

Challenges in Wire Sawing Ceramics

Industrial Ceramics Wire Sawing is a game-changer in precision machining, but it comes with its own set of challenges. The process, though highly effective, is not without obstacles that can impact the efficiency and quality of the final product. In this section, we’ll delve into some of the most common challenges faced in wire sawing ceramics and explore potential solutions and best practices to overcome these issues.

One of the primary challenges in Industrial Ceramics Wire Sawing is the hardness and brittleness of ceramic materials. Ceramics are known for their exceptional hardness, which makes them resistant to wear and high temperatures. However, this very property also makes them prone to cracking and chipping during the sawing process. The brittleness of ceramics can lead to significant material loss and reduced yield, which is a critical concern in industries where precision and efficiency are paramount.

Eine weitere Herausforderung ist die wear and tear on the wire saws themselves. The abrasive nature of ceramic materials can cause rapid degradation of the wire, leading to frequent replacements and increased operational costs. To mitigate this, manufacturers often use diamond-coated wires, which offer enhanced durability and cutting efficiency. However, even with diamond coatings, the wear and tear on the wire saws remain a significant issue that needs continuous monitoring and maintenance.

Die cooling and lubrication during the sawing process is another critical factor. Effective cooling and lubrication are essential to prevent overheating and reduce friction, which can lead to thermal damage and surface imperfections in the ceramic components. However, finding the right balance of coolant and lubricant can be challenging, as excessive use can lead to contamination and environmental concerns, while insufficient use can result in poor cutting performance and increased tool wear.

Precision and accuracy are paramount in Industrial Ceramics Wire Sawing, but achieving these can be difficult due to the vibration and stability issues during the cutting process. Any slight vibration or instability can lead to deviations in the cut, resulting in components that do not meet the stringent specifications required in high-performance applications. To address this, advanced wire cutting machines are equipped with vibration-damping systems and precision control mechanisms to ensure stable and accurate cuts.

Moreover, the complex geometries and intricate designs of some ceramic components pose additional challenges. Wire sawing is often used to create complex shapes and fine details in ceramics, but achieving these intricate designs requires advanced machinery and skilled operators. The process demands meticulous planning and execution to ensure that the final product meets the desired specifications without compromising on quality or performance.

Finally, the cost and availability of high-quality wire saws can be a limiting factor. High-performance diamond wire cutting machines and diamond-coated wires come at a premium, and their availability can be limited, especially in regions with less developed industrial infrastructure. This can lead to increased production costs and longer lead times, which can be a significant barrier for small and medium-sized enterprises looking to adopt wire sawing technology for ceramics.

In conclusion, while Industrial Ceramics Wire Sawing offers numerous benefits in terms of precision and performance, it is not without its challenges. By understanding these challenges and implementing best practices, such as using advanced wire cutting machines, optimizing cooling and lubrication, and ensuring stability and precision, manufacturers can overcome these obstacles and achieve high-quality results. As technology continues to evolve, we can expect further advancements in wire sawing techniques and materials, paving the way for even greater precision and efficiency in the machining of industrial ceramics.

Future Trends in Ceramics Wire Sawing

The world of Industriekeramik Drahtsägen is rapidly evolving, with new technologies and methodologies emerging that promise to revolutionize the industry. As we look to the future, several key trends are expected to shape the landscape of ceramics wire sawing. These advancements will not only enhance precision and efficiency but also open up new possibilities for applications across various sectors.

One of the most exciting developments is the integration of Automatisierung und smart technologies into wire sawing processes. Automation allows for more consistent and precise cuts, reducing the likelihood of human error. Smart technologies, such as AI and machine learning, enable wire saws to optimize their performance in real-time, adjusting parameters to achieve the best possible results. This is particularly beneficial for complex and high-precision tasks, ensuring that each cut is executed with the utmost accuracy.

Another trend to watch is the advancement of diamond wire cutting machines. These machines are becoming more sophisticated, with improvements in wire materials and coatings that enhance their durability and cutting efficiency. The use of diamond-coated wires, for instance, is gaining traction due to their ability to cut through even the hardest ceramics with minimal wear and tear. This not only extends the lifespan of the wire but also reduces downtime and maintenance costs.

In addition to technological advancements, there is a growing emphasis on Nachhaltigkeit within the industry. Manufacturers are increasingly looking for ways to reduce waste and minimize the environmental impact of their operations. This includes the development of more efficient wire sawing techniques that generate less material waste and the use of eco-friendly materials and coatings. By adopting sustainable practices, companies like Shine are not only contributing to environmental conservation but also enhancing their brand reputation and competitiveness in the market.

Furthermore, the rise of Personalisierung und Flexibilität in wire sawing machines is another significant trend. Modern wire saws are being designed to accommodate a wide range of materials and applications, allowing for greater versatility in their use. This is particularly important in industries such as electronics, aerospace, and medical devices, where the demand for customized and high-performance components is on the rise. With the ability to tailor the sawing process to specific requirements, companies can achieve better results and meet the unique needs of their clients.

As we look ahead, it is clear that the future of Industrial Ceramics Wire Sawing is bright. With ongoing innovations in automation, smart technologies, diamond wire cutting machines, sustainability, and customization, the industry is poised for significant growth and transformation. Companies like Shine are at the forefront of these developments, continually pushing the boundaries of what is possible in ceramics wire sawing. By staying ahead of the curve and embracing these trends, businesses can ensure they remain competitive and deliver the highest quality products to their customers.

In conclusion, the future of Industrial Ceramics Wire Sawing is set to be defined by technological advancements, increased sustainability, and greater customization. As these trends continue to evolve, they will undoubtedly lead to more efficient, precise, and environmentally friendly wire sawing processes. For companies like Shine, this presents an exciting opportunity to innovate and excel in the ever-changing landscape of ceramics machining.

Häufig gestellte Fragen

- What is wire sawing technology in industrial ceramics?Wire sawing technology involves using a wire embedded with abrasive materials to cut through industrial ceramics with high precision. This method is essential for achieving accurate and smooth cuts in various high-performance components.

- What are the advantages of wire sawing in ceramics?Wire sawing offers several advantages when machining ceramics, including reduced material waste, enhanced accuracy, and improved surface quality. These benefits make it a preferred method in industries requiring precise and efficient cutting.

- What types of wire saws are used in ceramics machining?There are various types of wire saws used in ceramics machining, such as diamond wire saws and electroplated wire saws. Each type has unique features and is suitable for different applications depending on the specific requirements of the machining process.

- What materials and coatings are used for wire saws?Wire saws are typically made from high-strength materials like steel and are coated with abrasive substances such as diamond or cubic boron nitride. These materials and coatings enhance the efficiency and longevity of the sawing process.

- In which industries is wire sawing of ceramics commonly used?Wire sawing of ceramics is commonly used in various industries, including electronics, aerospace, and medical devices. The precision and efficiency of this method make it ideal for producing high-performance components in these fields.

- What are the common challenges faced in wire sawing ceramics?Common challenges in wire sawing ceramics include wire breakage, uneven cuts, and excessive wear on the wire. Addressing these issues requires careful selection of wire materials, proper machine maintenance, and optimized cutting parameters.

- What are the future trends in ceramics wire sawing?Future trends in ceramics wire sawing include advancements in wire materials and coatings, automation of the sawing process, and the development of more efficient and precise cutting technologies. These trends are expected to further enhance the capabilities of wire sawing in precision machining.