Table of Contents

Introduction

Diamond wire cutting is an advanced technology that utilizes diamond-coated wires to slice through a variety of materials with exceptional precision and efficiency. One of its remarkable applications is in cutting brittle materials, where its unique properties make it an ideal tool for achieving precise cuts without causing excessive damage. This article explores the capabilities of diamond wire cutting in processing various brittle materials, highlighting its advantages and applications.

Diamond Wire Cutting: A Brief Overview

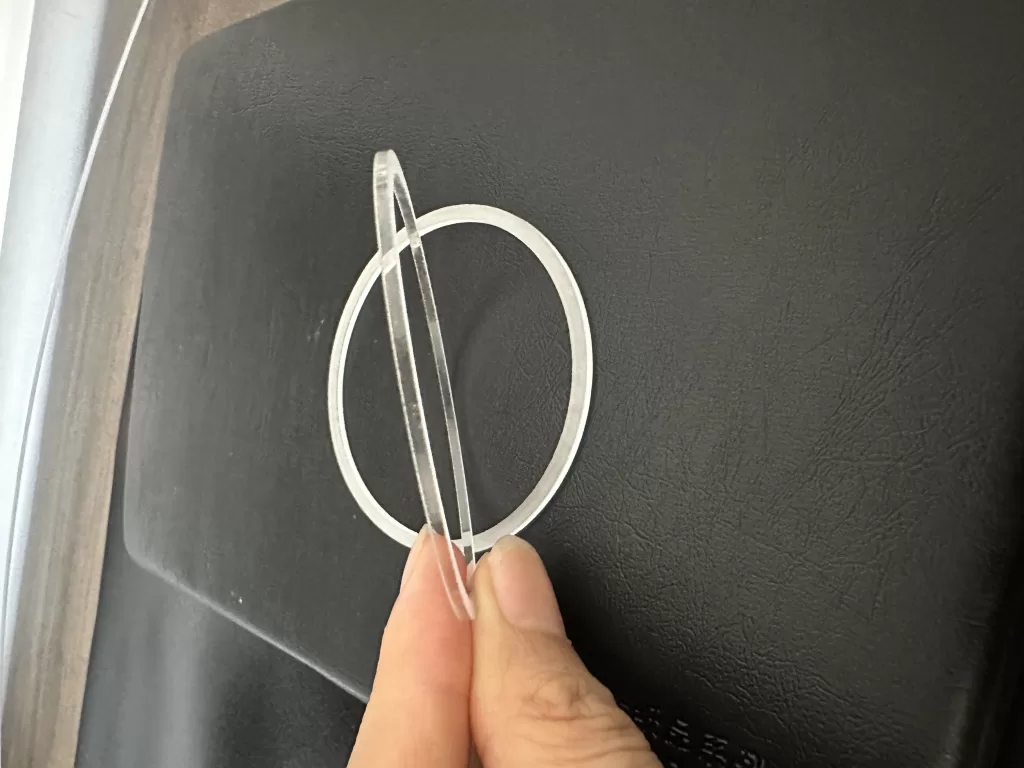

Diamond wire saw involves the use of a wire coated with diamond particles, which are the hardest known material. This technique is highly efficient and minimizes material loss due to its reduced kerf width – the width of the cut – compared to traditional cutting methods. Additionally, the inherent hardness of diamond makes it an effective tool for cutting hard and brittle materials with minimal heat generation.

Materials Suitable for Diamond Wire Saw

Ceramics

Ceramics are known for their exceptional hardness and brittleness, which can make traditional machining methods challenging. Diamond wire saw offers a solution by maintaining precise control over the cutting process and reducing the risk of fractures or cracks.

Glass

Glass, another brittle material, is commonly used in industries such as architecture, electronics, and optics. Diamond wire saw can create intricate shapes and precise edges in glass without compromising its structural integrity.

Semiconductor Materials

Semiconductor materials like silicon wafers are used in the electronics industry to produce microchips and other components. Diamond wire cutting ensures the accurate separation of these delicate materials without causing unwanted stress or damage.

Advanced Ceramics

Advanced ceramics, used in aerospace and medical applications, often require intricate cuts and shapes. Diamond wire saw offers the precision necessary for crafting these intricate designs without compromising the material’s mechanical properties.

Brittle Composite Materials

Many composite materials that combine brittle components, such as carbon fiber-reinforced polymers, can be challenging to cut accurately. Diamond wire saw provides a solution that allows for clean cuts without fraying or splintering.

Advantages of Diamond Wire Cutting

Precision

Diamond wire cutting is known for its high precision, making it an ideal choice for creating intricate designs and accurate cuts in brittle materials.

Minimal Material Loss

The narrow kerf width of diamond wire saw results in minimal material wastage, which is particularly important when working with expensive or limited materials.

Reduced Fractures

Traditional cutting methods can lead to fractures and cracks in brittle materials. Diamond wire cutting’s controlled process minimizes the risk of such structural damage.

Smooth Surface Finish

The cutting action of diamond-coated wires produces a smoother surface finish, reducing the need for additional post-processing steps.

High Efficiency

Diamond wire saw is efficient, enabling faster material processing while maintaining quality.

Applications in Various Industries

1. Aerospace and Automotive Manufacturing:

- Precision Crafting: Wire cutting technology, particularly EDM, is essential for shaping complex parts from hard metals like titanium and stainless steel.

- Safety and Performance: The high precision of wire cutting ensures that aerospace and automotive components meet stringent safety standards.

2. Electronics Industry:

- Semiconductor Fabrication: In the electronics sector, wire cutting is crucial for slicing silicon wafers, fundamental in microchip and integrated circuit production.

- Accuracy and Efficiency: The method’s precision and minimal material damage are key to the functionality and reliability of electronic devices.

3. Medical Field:

- Medical Device Manufacturing: Wire cutting technology is used to produce intricate components for medical devices, including implants and surgical tools.

- Standards Compliance: The ability to precisely cut biocompatible metals and other materials ensures these devices adhere to strict medical standards.

4. Construction and Stone Processing:

- Material Handling: Wire saw cutting, often utilizing diamond-impregnated wires, is employed for cutting large stone and concrete blocks.

- Quarrying and Construction: This method is pivotal in quarrying and preparing materials for construction projects, combining precision with the capability to handle large-scale materials.

5. Artistic Applications:

- Sculptures and Decorative Pieces: Beyond industrial applications, artists and designers use wire cutting technology for creating intricate sculptures and artworks.

- Versatility and Creativity: The technology demonstrates its versatility and adaptability in artistic endeavors.

Summary:

Diamond wire cutting has emerged as a game-changing technology in the realm of materials processing, particularly for brittle materials. Its exceptional precision, minimal material loss, and reduced risk of fractures make it an indispensable tool across various industries, from architecture to electronics to aerospace. As this technology continues to evolve, its applications are likely to expand even further, contributing to the advancement of cutting-edge industries and the creation of innovative products.