Table of Contents

Introduction of diamond wire cutting equipment

In the domain of industrial cutting, diamond wire cutting technology stands as a paradigm of innovation and precision. This 1500-word article delves into the intricacies of diamond wire cutting, a method that has revolutionized material cutting across various industries. The core of this technology lies in its use of diamond-impregnated wire, offering unmatched cutting capabilities.

Understanding Diamond Wire Cutting

Diamond wire cut is a method where a wire impregnated with diamond grit is used to cut through materials. The diamonds, being the hardest material on the Earth, allow the wire to cut through almost any material with precision. This technology is highly valued in sectors that demand accuracy and minimal damage to the material, such as construction, mining, electronics, and gemstone processing.

Types of Diamond Wire Cutting Equipment

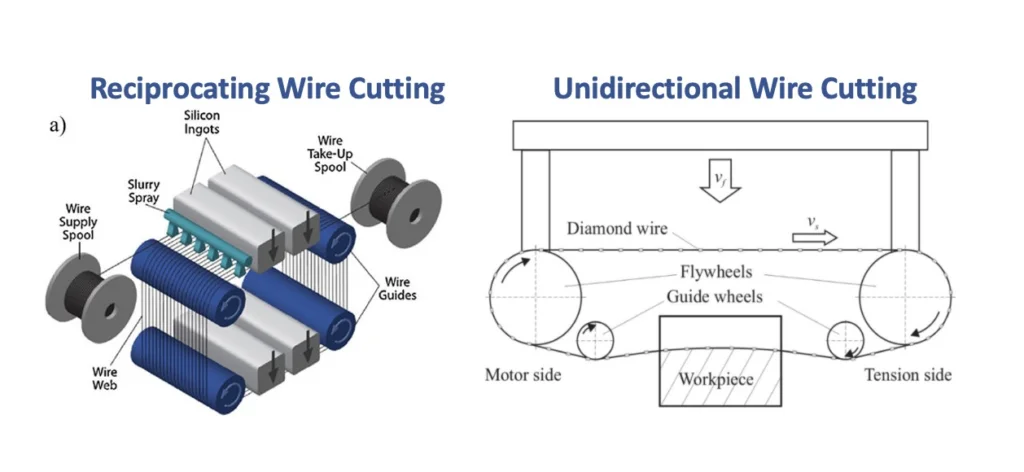

Diamond wire cut equipment can be categorized based on its structural design and the type of wire used.

1. Multi Wire Structure

- Overview: Multi wire structures use several diamond wires mounted on spools. This setup is ideal for simultaneous cutting, enhancing efficiency and productivity.

- Applications: Commonly used in stone quarrying and in industries where large-scale, parallel cutting of materials is required.

2. Single Wire Structure

Single wire structures are further divided into two types, each with unique characteristics:

a. Endless Diamond Wire Type

- Design: This innovative design features a continuous loop of diamond wire, eliminating the need for frequent wire changes.

- Advantages: Offers consistency in cutting, reduced downtime, and increased efficiency, making it ideal for precision cutting tasks.

b. Diamond Wire on Spool Type

- Design: A traditional setup where the diamond wire is wound on a spool.

- Usage: Versatile and adaptable for various cutting applications, though it may not match the efficiency of the endless wire type.

The Advantages of Diamond Wire Cutting

Diamond wire cut technology offers several advantages over traditional cutting methods:

- Precision Cutting: The fine, diamond-impregnated wire allows for precise cuts, reducing material waste and enhancing the quality of the cut.

- Versatility: Capable of cutting a wide range of materials, from concrete and stone to metals and delicate semiconductor wafers.

- Efficiency: Especially with the endless diamond wire type, this method offers increased efficiency, reducing the time and cost involved in cutting processes.

Innovations in Diamond Wire Cutting

The field of diamond wire cutting is ripe with innovations:

- Improved Diamond Impregnation: Advances in how diamonds are impregnated into the wire have enhanced the cutting ability and life of the wire.

- Automation and Control: Integration of CNC technology and automated controls has improved the precision and repeatability of cuts.

- Eco-Friendly Methods: Modern diamond wire cut methods are being developed to be more environmentally friendly, reducing water and energy consumption.

Applications of Diamond Wire Cut

Diamond wire cutting technology has found applications in numerous fields:

- Construction and Demolition: Used for cutting concrete, stone, and reinforced structures.

- Mining: In quarrying, diamond wire cut allows for precise extraction of stone and minerals.

- Semiconductor Manufacturing: Essential for slicing silicon wafers in the production of microchips.

- Gemstone and Glass Cutting: Used for delicate and precise cutting tasks in gemstone processing and glass manufacturing.

Challenges and Solutions in Diamond Wire Cutting

While diamond wire cut offers many advantages, it also faces challenges such as wire breakage, maintenance, and the need for specialized skills. Ongoing research and development are focused on creating more durable wires, enhancing machine reliability, and developing user-friendly interfaces.

Future Trends in Diamond Wire Cut

The future of diamond wire cut looks promising with trends like:

- Advanced Material Science: Development of new materials for wires to enhance durability and cutting efficiency.

- Integration of AI and IoT: Use of artificial intelligence and the Internet of Things for smarter, more efficient cutting processes.

- Sustainability Focus: Greater emphasis on eco-friendly cutting processes.

Selecting the Right Diamond Wire Cutting Equipment

Choosing the right diamond wire cut equipment involves considering the material type, desired precision, and specific application. Factors such as the size of the project, cutting speed, and cost efficiency play crucial roles in this decision.

Maintenance and Safety in Diamond Wire Cut

Proper maintenance is essential for the longevity and optimal performance of diamond wire cutting machines. Regular checks and timely replacements are key, along with strict adherence to safety guidelines to prevent accidents.

Conclusion

Diamond wire cut technology, with its various equipment types and cutting-edge applications, represents a significant advancement in industrial cutting. From the multi-wire to the single wire, and particularly the endless diamond wire types, this technology offers a blend of precision, efficiency, and versatility. As industries evolve, the role of diamond wire cut is set to become even more pivotal, driving innovation and efficiency in material cutting processes.