Table of Contents

Introduction of the advantages of diamond wire cutting equipment

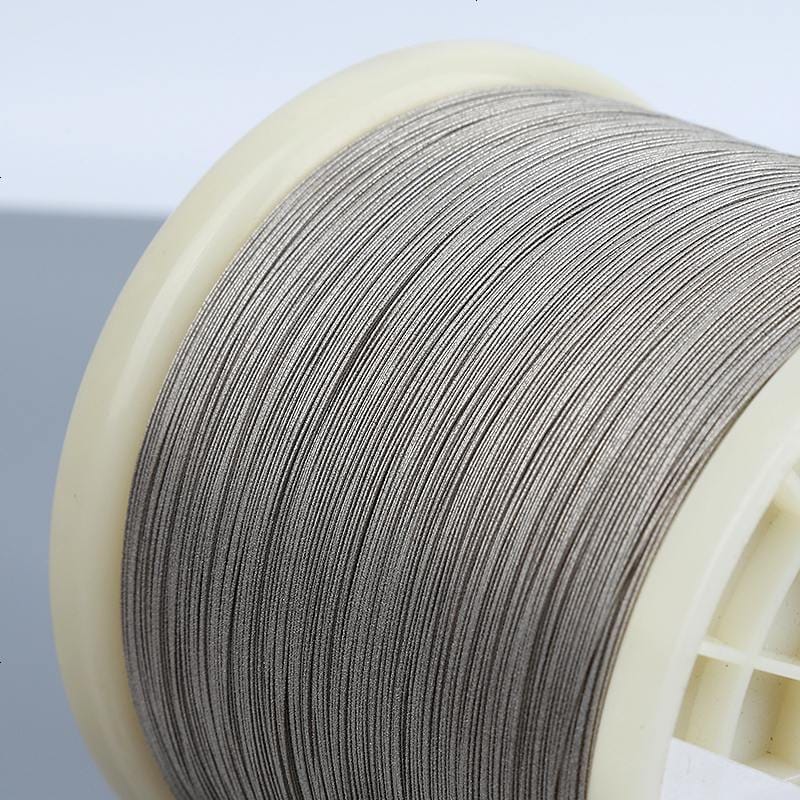

Diamond wire cutting is a cutting-edge technology that has revolutionized various industries, including construction, manufacturing, and mining. This technique employs a thin wire embedded with industrial diamonds to slice through materials with precision and efficiency. In this article, we will explore the key advantages of diamond wire cutting equipment, highlighting its contributions to increased productivity, reduced waste, and enhanced versatility.

1. Precision and Accuracy

One of the most significant advantages of diamond wire cutting equipment is its unparalleled precision and accuracy. The use of industrial diamonds in the wire’s construction enables it to cut through even the toughest materials with minimal deviation. This level of precision is particularly beneficial in industries such as electronics manufacturing, where intricate components require clean and precise cuts to maintain their functionality. Additionally, precision cutting reduces the need for extensive post-processing, saving both time and resources.

2. Reduced Material Waste

Conventional cutting methods often result in significant material wastage due to the wider cutting paths and the generation of heat, which can lead to distortion or damage. Diamond wire cutting minimizes waste by creating narrow cuts and generating less heat during the cutting process. The narrow kerf produced by the diamond wire allows for tighter nesting of parts, optimizing material usage and reducing overall waste. This advantage is especially valuable in industries that work with expensive materials or aim to meet strict sustainability goals.

3. Versatility in Materials

Diamond wire cutting equipment showcases remarkable versatility when it comes to cutting various materials. From soft and delicate materials like foam and rubber to the toughest substances like concrete and metal, this technology can adapt to diverse material characteristics without compromising quality. This adaptability has led to its adoption in industries ranging from construction and aerospace to arts and crafts. Manufacturers and artisans alike can benefit from a single cutting solution that accommodates an array of materials.

4. Minimized Environmental Impact

Compared to traditional cutting methods that rely on abrasive tools, diamond wire cutting is a more environmentally friendly option. The absence of abrasive particles and the reduction in heat generation contribute to a cleaner and safer working environment. Additionally, the reduced material wastage directly translates into fewer resources being extracted and processed, aligning with sustainable practices and minimizing the industry’s ecological footprint.

5. Enhanced Safety

Safety is paramount in any industrial setting, and diamond wire cutting equipment prioritizes this aspect as well. The technology reduces the need for manual intervention during cutting, minimizing the risk of accidents or injuries to operators. Automated systems, when combined with advanced sensors and monitoring, ensure that the cutting process is carried out with precision and minimal human involvement. This improvement in safety conditions enhances worker morale and reduces the likelihood of workplace incidents.

6. Cost Efficiency

While the initial investment in diamond wire cutting equipment might appear substantial, its long-term cost efficiency is undeniable. The precision cutting minimizes material wastage, leading to significant savings in raw materials. Moreover, the reduction in secondary processing and finishing operations further optimizes resource utilization. As a result, the overall production cycle becomes more streamlined, leading to shorter lead times and increased profitability.

Conclusion

Diamond wire cutting equipment has emerged as a game-changer in various industries due to its numerous advantages. Its precision, reduced material waste, versatility, minimized environmental impact, enhanced safety, and cost efficiency collectively contribute to a more efficient and sustainable production process. As technology continues to advance, it is likely that diamond wire cutting will play an even more pivotal role in shaping the future of manufacturing, construction, and other sectors that require precise and efficient material cutting techniques.