Table of Contents

Jadeite, a precious gemstone known for its vibrant colors and exquisite translucency, has captivated the hearts of people for centuries. The intricate art of cutting and shaping jadeite is a testament to human craftsmanship, and one technique that stands out in achieving precise and efficient cuts is the Diamond Wire Cutting Technology. This advanced method revolutionizes the way jadeite is transformed into stunning pieces of art.

Introduction to Diamond Wire Cutting Technology

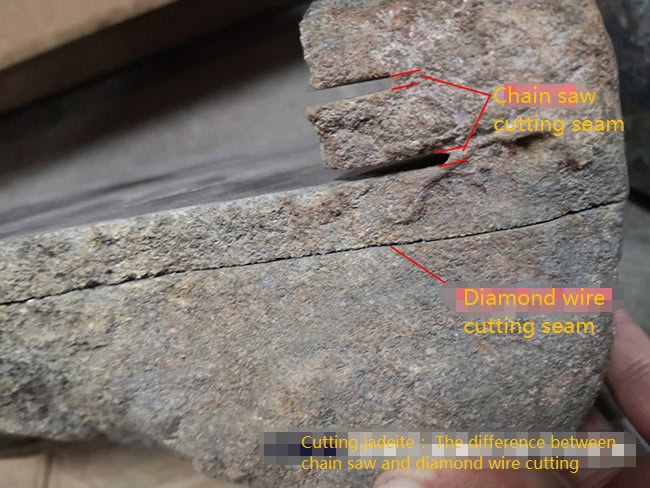

Diamond Wire Cutting Technology is a cutting-edge process that employs a thin, flexible wire embedded with industrial diamonds to slice through materials with exceptional precision. Originally developed for cutting hard and brittle materials in the construction industry, this technology has found its way into the world of gemstone processing, particularly in shaping jadeite. The technique has proven to be highly effective, minimizing wastage and enhancing the overall yield of top-quality jadeite pieces.

The Mechanism Behind Diamond Wire Cutting

At the core of Diamond Wire Cutting Technology is the use of industrial-grade diamonds. Diamonds are the hardest natural material known, and they are well-suited for cutting and shaping even the toughest gemstones like jadeite. The diamonds are securely fixed to a flexible wire, creating a cutting tool that can move in a controlled manner.

The process begins with securing the jadeite material and configuring the cutting parameters, such as wire speed and tension. The diamond-embedded wire is then set into motion, gently slicing through the jadeite. Unlike traditional methods that might generate excessive heat and vibration, diamond wire cutting generates minimal heat and leaves a smoother surface finish, preserving the natural beauty of the gemstone.

Advantages of Diamond Wire Cutting for Jadeite

1. Precision

Diamond Wire Cutting Technology enables intricate and detailed cuts that were previously challenging to achieve. This precision allows artisans to create complex designs that accentuate the natural patterns and colors of the jadeite.

2.Reduced Material Loss

Traditional cutting methods often result in substantial material wastage due to the width of the cutting tool. Diamond wire, being thin, reduces this wastage significantly, maximizing the utilization of the raw jadeite material.

3.Efficiency

The efficiency of diamond wire cutting translates into shorter production times. This is especially valuable for meeting the demands of the market while maintaining high-quality standards.

4.Minimized Damage

The controlled cutting process minimizes the risk of damaging the gemstone due to excessive force or heat. This is essential when working with valuable and delicate materials like jadeite.

5.Versatility

Diamond wire cutting is adaptable to various shapes and sizes, making it suitable for custom orders and unique designs. Whether it’s intricate sculptures or polished cabochons, the technology can cater to a wide range of creative visions.

Challenges and Future Developments

While Diamond Wire Cutting Technology has transformed the jadeite cutting landscape, challenges remain. The initial setup costs and maintenance of the equipment can be substantial. Moreover, specialized training is required to operate the machinery effectively. However, as technology advances and becomes more accessible, these challenges are likely to diminish.

Looking ahead, the integration of automation and computerized controls holds promise for further enhancing the precision and efficiency of diamond wire cutting. The use of AI-driven algorithms to optimize cutting paths and parameters could lead to even finer results, reducing human error and boosting productivity.

Conclusion

In the realm of crafting exquisite jadeite pieces, Diamond Wire Cutting Technology has emerged as a game-changer. Its precision, reduced material wastage, and efficiency have elevated the art of jadeite cutting to new heights. As this technology continues to evolve and become more refined, it is set to carve a dazzling future for the world of jadeite craftsmanship, where innovation and tradition harmoniously converge.