As we delve into the realm of diamond wire machines, previously highlighted in our exploration of wire cutting machines, we invite you on a journey to uncover the myriad of possibilities they offer. Whether it’s the artistry of creating mesmerizing sculptures or the precision required in semiconductor manufacturing, these machines, particularly those from SHINE, stand at the forefront of innovation. Join us as we explore the transformative impact of diamond wire machines on various industries and how they continue to shape the future of cutting technology.

Have you ever wondered what drives the precision behind the world’s most intricate designs and technologies? How do industries manage to cut through the toughest materials with immaculate precision? The answer lies in the innovative use of diamond wire machines, a technological marvel that has revolutionized the way we approach material cutting. From the crafting of delicate gemstones to the slicing of robust silicon crystals for electronics, these machines embody the pinnacle of precision and efficiency.

The Ultimate Guide to Diamond Wire Machines

In the dynamic world of cutting technologies, diamond wire machines stand out for their precision, efficiency, and versatility. These machines, employing a wire embedded with diamond particles, have revolutionized various industries by providing superior cutting capabilities for a wide range of materials. This comprehensive guide will explore the ins and outs of diamond wire machines, from their fundamental operation to advanced applications, ensuring you have the knowledge to choose and utilize these machines effectively.

Table of Contents

Overview of Diamond Wire Machines

Diamond wire machines utilize a wire impregnated with diamond, the hardest material on Earth, to cut through various substances. These machines are pivotal in industries such as construction, mining, electronics manufacturing, and stone and marble cutting, thanks to their ability to make precise cuts with minimal waste.

- Introduction to Diamond Wire Technology: Discover the cutting-edge technology behind SHINE diamond wire machines, renowned for their precision and efficiency in cutting diverse materials.

- Comparative Analysis of Diamond Wire Machine Types: Dive into a detailed comparison between mono-wire and multi-wire machines, highlighting their specific applications and benefits in various industries.

- Advantages of SHINE Diamond Wire Machines: Explore the multiple benefits these machines offer, including precision cutting, efficiency, material versatility, and safety enhancements, distinguishing them in the cutting technology sector.

- Innovative Uses Across Industries: Uncover the wide range of applications for SHINE diamond wire machines, from intricate stone and marble work to cutting-edge silicon and sapphire processing for electronics.

- Sustainability and Safety Features: Learn about the eco-friendly aspects and safety measures integrated into SHINE diamond wire machines, ensuring reduced waste and enhanced operator safety.

- Maintenance and Operation Insights: Gain valuable knowledge on maintaining and operating diamond wire machines to maximize their lifespan and performance, ensuring your investment continues to deliver exceptional results.

Understanding Diamond Wire Machines

What is a Diamond Wire Machine?

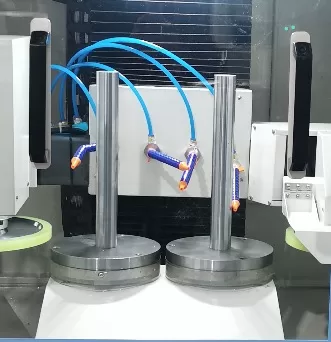

A diamond wire machine is a cutting tool that uses a wire coated with diamond particles to cut through various materials. The basic operation involves driving the diamond-impregnated wire through the material to be cut, with water often used as a coolant to reduce heat and remove debris.

Types of Diamond Wire Machines

- Mono-Wire Machines: Designed for simpler, smaller cuts, these machines use a single wire to slice through materials.

- Multi-Wire Machines: Capable of making multiple cuts simultaneously, these machines increase productivity for industrial applications.

Advantages of Using Diamond Wire Machines

- Precision Cutting: The small diameter and flexibility of the wire allow for intricate and precise cuts.

- Efficiency and Speed: These machines cut faster and more efficiently than traditional cutting methods.

- Versatility in Materials: Diamond wire machines can cut through almost any material, from soft marble to hard silicon and sapphire.

- Reduced Waste and Increased Safety: The precision of these machines minimizes material waste and enhances safety by reducing the need for manual intervention.

Choosing the Right Diamond Wire Machine

Factors to Consider

- Material Compatibility Assessment: Identify the specific materials your projects entail, from gemstones to silicon crystals, ensuring the chosen SHINE diamond wire machine meets your cutting needs.

- Precision and Quality Demands: Evaluate the precision level and cut quality required for your applications, determining which SHINE machine model aligns with your quality standards.

- Volume and Efficiency Considerations: Assess your production volume to decide if a mono-wire or multi-wire SHINE machine is more suited to your operational efficiency needs.

- Machine Features Evaluation: Focus on essential features such as wire speed, tensioning systems, and cooling mechanisms that differentiate SHINE machines,

- Cost Analysis:

- Supplier Reliability and Support: Ensure the purchase from a reputable supplier or directly from SHINE, considering the availability of customer support, parts, and service to maintain machine performance.

By thoroughly considering these factors, users can make informed decisions when selecting a diamond wire machine, optimizing their cutting operations with the reliability and innovation of SHINE technology.

Buying Guide for Diamond Wire Machines

When venturing into the realm of diamond wire machines, whether for industrial, construction, or artistic applications, selecting the right equipment is crucial. This guide focuses on the SHINE brand, known for its precision and reliability, offering insights into making an informed purchase.

Understanding Your Needs

- Material Specifics: Begin by identifying the materials you plan to cut. SHINE diamond wire machines are versatile, capable of handling everything from marble and stone to silicon and sapphire.

- Cutting Precision: Determine the level of precision required for your projects. Higher precision demands might necessitate advanced SHINE models.

- Production Volume: Assess your expected production volume to choose between mono-wire and multi-wire configurations, ensuring efficiency and throughput align with your needs.

Evaluating Machine Features

- Wire Speed: The cutting speed affects both the efficiency of your operations and the finish of the cut material. SHINE machines offer adjustable wire speeds to accommodate different materials and cutting conditions.

- Tensioning System: A robust tensioning system is vital for consistent cutting performance. SHINE’s innovative tensioning solutions ensure smooth, precise cuts.

- Cooling System: Given the intense friction generated during cutting, an effective cooling system is essential. SHINE machines come equipped with cooling systems that prolong wire life and prevent material damage.

New vs. Used Machines

- New Machines: Opting for a new SHINE diamond wire machine ensures you get the latest technology with full manufacturer support and warranty. Ideal for businesses looking for long-term reliability and performance.

- Used Machines: While more budget-friendly, used machines require thorough inspection to ensure they meet operational standards. Consider the machine’s age, wear, and availability of replacement parts.

Where to Buy

- Direct from SHINE: Purchasing directly ensures authenticity and access to comprehensive customer support and service.

- Authorized Dealers: Authorized dealers can offer localized support and service, often with additional benefits such as installation assistance.

- Online Marketplaces: While potentially offering competitive prices, ensure you verify the seller’s credibility and the machine’s condition when buying through online platforms.

Investment Considerations

- Initial Cost vs. Operational Costs: Weigh the initial investment against potential operational costs, including maintenance and parts replacement. SHINE machines, while possibly higher in initial cost, offer lower long-term expenses due to their durability and efficiency.

- Support and Service: Factor in the availability and cost of ongoing support and service. SHINE’s global network of dealers and service centers provides accessible assistance and spare parts.

Final Thoughts

Selecting the right diamond wire machine is a significant decision that impacts your operational efficiency and product quality. By focusing on your specific needs, evaluating key features, and considering both new and used options, you can find a SHINE machine that meets your requirements. Always prioritize quality, support, and performance to ensure your investment delivers the desired returns in precision cutting applications.

Elevate your cutting precision with our Quartz Cutting Machinery, a state-of-the-art solution designed for those who demand the utmost accuracy and efficiency. Ideal for a broad range of applications, from intricate jewelry design to high-tech manufacturing, this machine embodies the innovative spirit of SHINE, offering unparalleled performance. Discover the difference precision makes and transform your cutting process today.

WHERE TO BUY THE Quartz Cutting Machinery?

Operating a Diamond Wire Machine

Setting Up Your Machine

Proper installation and safety checks are crucial before operation. This includes ensuring the wire is correctly installed and tensioned, and that all safety features are functional.

Best Practices for Operation

- Regularly inspect the wire and machinery for wear.

- Follow the manufacturer’s guidelines for wire speed and material handling.

- Maintain a consistent flow of coolant to prevent overheating.

Maintenance Tips

Regular maintenance extends the lifespan of both the wire and the machine, including timely replacement of worn parts and routine checks of the cooling and tensioning systems.

Troubleshooting Common Issues

Common problems include wire breakage, uneven cuts, and machine overheating, which can often be resolved by adjusting the tension, speed, or cooling flow.

Comparing Diamond Wire Machines

In the market for diamond wire machines, the options vary significantly in terms of functionality, performance, and application. A detailed comparison focusing on SHINE machines versus other brands reveals crucial distinctions that can guide users in making an informed decision tailored to their cutting needs.

Performance and Precision

- SHINE Diamond Wire Machines: Known for their exceptional precision, SHINE machines are engineered to produce the finest cuts with minimal material waste. The advanced tensioning and wire speed control systems contribute to their superior performance, making them ideal for intricate and demanding cutting tasks.

- Other Brands: While many offer satisfactory performance, they may not match the precision level of SHINE machines, especially in complex or delicate cutting operations. The efficiency of tensioning systems and speed control can vary, affecting the overall cut quality.

Versatility

- SHINE Machines: SHINE stands out for its versatility across a wide range of materials, including but not limited to stone, marble, silicon, and sapphire. Their machines are designed to accommodate different wire types and sizes, enhancing their adaptability to various cutting scenarios.

- Other Brands: Most competitors offer machines tailored to specific materials or cutting conditions. While effective within their niche, they may lack the broad adaptability of SHINE machines, potentially limiting their application in diverse operational settings.

Durability and Maintenance

- SHINE Machines: Durability is a hallmark of SHINE diamond wire machines, built to withstand the rigors of continuous operation. They are designed for easy maintenance, with accessible components and a global network for support and parts.

- Other Brands: Durability can be inconsistent among other brands, with some machines requiring frequent maintenance or part replacements, which can increase operational costs and downtime.

Cost-Effectiveness

- SHINE Machines: Initially, SHINE machines might appear as a higher investment compared to some competitors. However, their efficiency, lower maintenance costs, and longer lifespan ensure a better return on investment over time.

- Other Brands: While some brands may offer lower upfront costs, the total cost of ownership can be higher due to increased maintenance, higher operational costs, and potentially shorter machine lifespans.

Customer Support and After-Sales Service

- SHINE Machines: SHINE provides exemplary customer support and after-sales services, including comprehensive training, a global service network, and readily available parts. This commitment to customer satisfaction ensures users can maximize machine uptime and performance.

- Other Brands: The level of customer support varies significantly among competitors. Some may offer limited after-sales services or have a smaller network for parts and maintenance, impacting long-term usability and satisfaction.

Advanced Applications of Diamond Wire Machines

Beyond traditional cutting, diamond wire machines are used for innovative applications such as artistic creations and custom fabrication, showcasing their adaptability.

- Stone and Marble Sculpting: Explore the artistry possible with SHINE diamond wire machines, transforming blocks of stone and marble into intricate sculptures and architectural elements.

- Silicon Wafer Production: Dive into the high-tech world of semiconductor manufacturing, where SHINE machines excel in slicing silicon crystals into thin wafers with precision, critical for electronics and solar panels.

- Sapphire Cutting for Electronics: Uncover the role of SHINE diamond wire machines in cutting sapphire substrates, a process essential for creating durable screens and components in consumer electronics.

- Construction Material Shaping: Learn how SHINE machines are employed in cutting and shaping construction materials, from reinforced concrete to natural stone, enabling precise cuts for complex building designs.

- Artistic Creations in Glass and Metal: Investigate the use of SHINE diamond wire machines in the artistic domain, enabling creators to work with tough materials like glass and metal to produce innovative art pieces.

- Custom Fabrication for Industrial Applications: Discover the versatility of SHINE diamond wire machines in custom fabrication tasks, allowing for the production of specialized parts and components with unparalleled precision.

Conclusion

As we conclude our journey through the world of diamond wire machines, it’s clear that these tools are not just about cutting materials; they’re about unlocking potential and pushing boundaries across industries. From the meticulous creation of gemstone cutting machines to the precision of silicon crystal cutting, the versatility and efficiency of these machines are unparalleled. SHINE’s diamond wire machines represent the epitome of this innovation, offering solutions that transcend traditional cutting methods.

Are you ready to elevate your cutting capabilities to new heights? Explore our range of diamond wire machines, including our featured Quartz Cutting Machinery, and discover how SHINE can transform your production process. Embrace the future of cutting technology and take the first step towards unmatched precision and efficiency. Click to discover more and make your purchase today.

For in-depth tutorials and operational insights on diamond wire machines, check out our official YouTube channel: Watch Now! Your one-stop destination for mastering cutting-edge cutting technology.

4. FAQs

Q: How does a diamond wire machine differ from traditional cutting methods? A: Diamond wire machines offer superior precision and efficiency by using a wire impregnated with diamond particles, allowing them to cut through materials traditional methods cannot.

Q: Can diamond wire machines cut through any material? A: Yes, diamond wire machines are incredibly versatile and can cut through a wide range of materials, including gemstones, silicon, and construction materials, thanks to the hardness of the diamonds.

Q: What are the environmental impacts of using a diamond wire machine? A: While diamond wire machines are efficient and reduce waste, it’s important to consider the energy consumption and the source of the diamonds, aligning with SHINE’s commitment to sustainable practices.

Q: How often does the wire in a diamond wire machine need to be replaced? A: The lifespan of the wire depends on the material being cut and the frequency of use. Regular maintenance and proper use can extend its life.

Q: Can I use a diamond wire machine for custom fabrication? A: Absolutely, diamond wire machines are perfect for custom fabrication, allowing for precise cuts and creativity in designs, especially with SHINE’s advanced models.

Q: Where can I find tutorials or guides on operating a diamond wire machine? A: For authoritative tutorials and operational guides, visit SHINE’s YouTube channel at https://www.youtube.com/@endlessdiamondwireloop, offering a wealth of information for users at all levels.