Unveiling the Key Differences

Table of Contents

Introduction:

In the world of stone cutting and processing, diamond wire saw machines have become indispensable tools for various industries. These machines utilize the remarkable cutting capabilities of diamonds to slice through hard materials with precision and efficiency. However, within this category of equipment, two prominent variations exist: the diamond wire saw and the endless diamond wire saw machine.

In this article, we will delve into the key differences between these two technologies, exploring their features, advantages, and applications.

1,Diamond Wire Saw Machine:

The diamond wire saw is a highly versatile and widely used tool in the stone cutting industry. It employs a continuous loop of diamond-impregnated wire as the cutting medium. This wire is tensioned and guided through a series of pulleys, which drive the cutting process. The primary characteristics of diamond wire saw machines include:

a. Cutting Performance:

Diamond wire saw machines are renowned for their exceptional cutting performance, enabling precise and clean cuts on a wide range of materials, including granite, marble, concrete, and other natural or engineered stones.

b. Flexibility:

These machines offer flexibility in terms of cutting direction and shape. They can be used for straight-line cutting as well as complex curves, making them suitable for intricate designs and architectural elements.

c. Application Range:

Diamond wire saw machines are extensively employed in various industries, such as construction, mining, and monument fabrication. They are particularly useful for large-scale operations that require high-speed cutting and reduced material wastage.

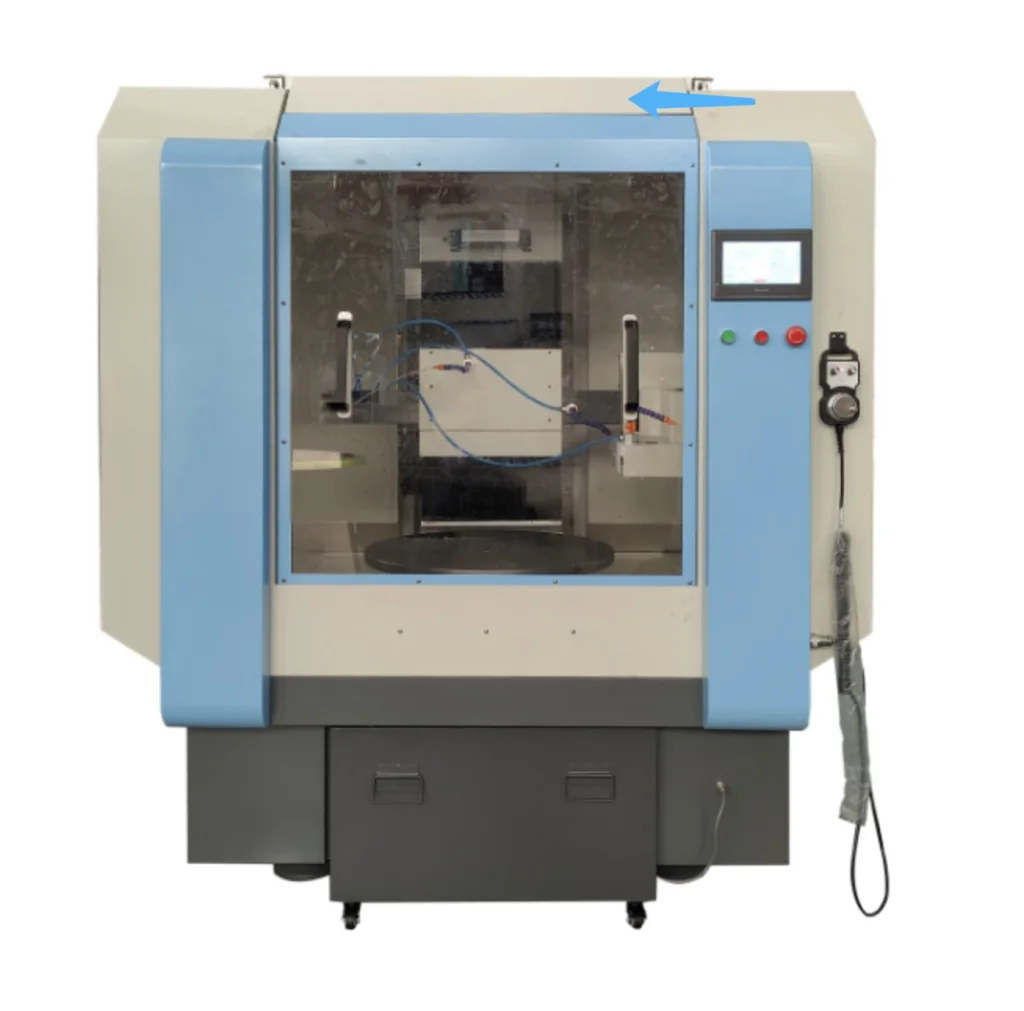

2,Endless Diamond Wire Saw Machine:

The endless diamond wire saw represents an advancement in cutting technology, offering distinct features that set it apart from traditional diamond wire saw machines. In this design, the diamond wire is transformed into a continuous loop with no visible joint. The key differentiating factors of endless diamond wire saw machines include:

a. Enhanced Cutting Speed:

Endless diamond wire saw machines boast significantly higher cutting speeds compared to their counterparts. The absence of visible joints reduces friction and resistance, enabling smoother movement and faster cutting rates. This feature leads to increased productivity and reduced processing time.

b. Improved Lifespan:

The continuous loop of the endless diamond wire minimizes stress concentration points, which often result in wire breakage. As a result, these machines offer enhanced durability and longevity, reducing downtime and maintenance costs.

c. Precision and Surface Quality:

Endless diamond wire saws deliver superior cutting precision and surface quality due to their smooth and uninterrupted cutting motion. The absence of joints eliminates the possibility of irregularities or uneven cuts, resulting in higher-quality finished products.

d. Specialized Applications:

The advanced features of endless diamond wire saw make them ideal for specific applications, such as cutting fragile or brittle materials that require delicate handling. Additionally, they are well-suited for cutting large blocks or slabs into thinner slices, maximizing material utilization.

Conclusion:

Diamond wire saw machines and endless diamond wire saws are both valuable tools in the stone cutting industry, each offering unique advantages and applications. While diamond wire saw machines provide flexibility and versatility, endless diamond wire saws excel in terms of cutting speed, durability, and precision. Choosing the right machine depends on the specific needs and requirements of the project at hand. By understanding the key differences between these technologies, professionals can make informed decisions to enhance productivity, optimize cutting processes, and achieve superior results in stone cutting and processing operations.