Table of Contents

Introduction

In the realm of quartz cutting , the mastery of cutting techniques is a cornerstone for progress. The emergence of advanced tools has revolutionized how we shape and manipulate materials. One such transformative innovation is the endless diamond wire saw, a remarkable solution that transcends conventional limitations in cutting hard materials, particularly challenging quartz specimens. This article delves into the remarkable capability of endless diamond wire saws to effortlessly and swiftly cut even the most formidable quartz specimens.

The Challenge of Large Quartz Cutting

Quartz, renowned for its unique combination of hardness and transparency, is a material of choice across various industries, from electronics to optics and solar energy. However, the inherent hardness of quartz also poses a challenge in processing. Large quartz specimens, whether for semiconductor applications, precision optics, or architectural uses, present a formidable challenge. Conventional cutting methods often struggle with these larger specimens due to the material’s hardness and potential for cracking.

Endless Diamond Wire Saw: A Cutting-Edge Solution

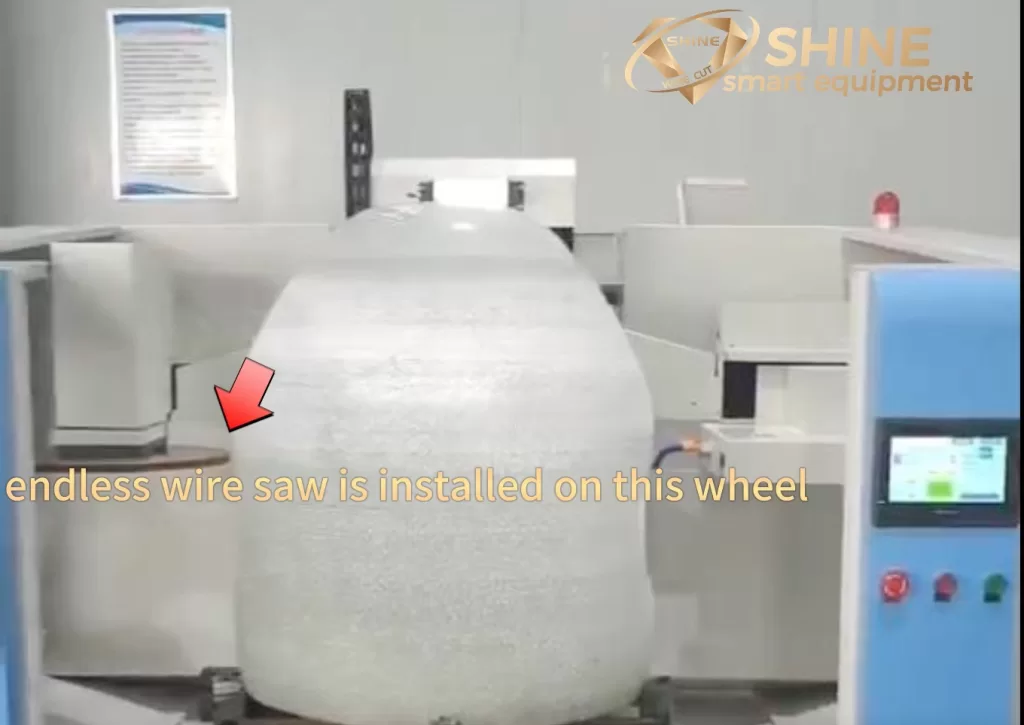

Endless diamond wire saws, equipped with their continuous loop of diamond-impregnated wire, are rewriting the rules of cutting. The remarkable capabilities of these machines are particularly evident when facing the challenge of cutting large quartz specimens. Here’s how endless diamond wire saws conquer this challenge:

- Efficiency in Action: The videos capturing the process reveal the seamless efficiency of endless diamond wire saws. The continuous motion of the diamond-impregnated wire gliding through the quartz demonstrates the technology’s ability to tackle large specimens with unparalleled ease.

- Swift Precision: The speed at which endless diamond wire saws operate is truly impressive. Despite the hardness of quartz, the wire saw effortlessly slices through the material, demonstrating the technology’s ability to cut large specimens quickly, without compromising precision.

- Minimized Material Waste: Large quartz specimens often come at a premium. The thinness of the diamond wire and its minimal kerf width ensure minimal material wastage. This not only optimizes material utilization but also reduces costs associated with cutting larger specimens.

- Enhanced Surface Quality: Cutting large quartz specimens often introduces the risk of surface imperfections due to the material’s hardness. However, the videos of endless diamond wire saws in action show that the technology achieves clean cuts with superior surface quality, eliminating the need for additional finishing steps.

- Reduced Risk of Cracking: The consistent, even pressure applied by endless diamond wire saws during cutting minimizes the risk of cracking, a significant concern with large quartz specimens. The videos showcase how the wire saw technology mitigates this issue, resulting in intact and usable pieces.

Video Evidence: A Testament to Endless Diamond Wire Saw’s Capability

The adage “seeing is believing” couldn’t be more apt in showcasing the prowess of endless diamond wire saws in cutting large quartz specimens. The videos depicting the process provide a visual testament to the technology’s ability to triumph over the challenges posed by hard, large quartz. These videos highlight the continuous, swift, and precise cutting motion that is at the heart of endless diamond wire saws’ success.

Unlocking New Possibilities

The implications of endless diamond wire saws’ capability to cut large quartz specimens are profound. Industries that rely on quartz, from semiconductor manufacturing to architectural design, can now explore new possibilities. Large and intricate quartz cutting components that were once deemed difficult or even impossible to cut can now be realized with precision and efficiency.

Conclusion

Endless diamond wire saws have not only transformed cutting technology but have also opened the door to new frontiers in processing challenging materials like large quartz specimens. The videos capturing the process provide compelling evidence of the technology’s ability to effortlessly cut through even the most formidable quartz cutting . As industries continue to seek innovative solutions for their cutting needs, endless diamond wire saws stand as a beacon of advancement, enabling the realization of intricate and large-scale quartz components with unmatched precision and efficiency.