Table of Contents

Introduction:

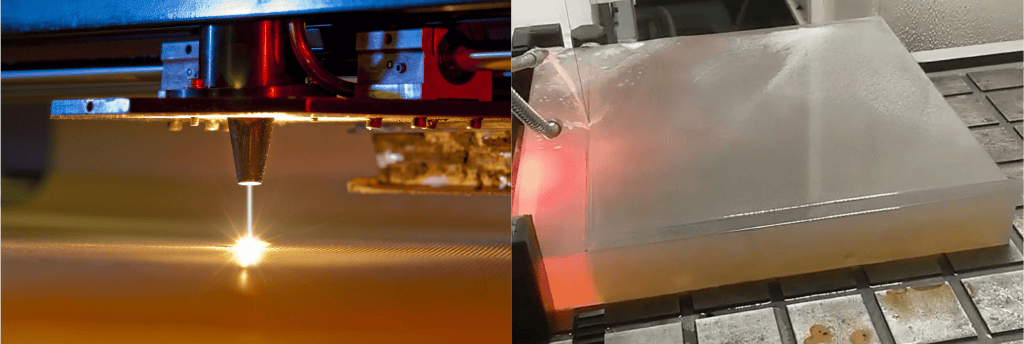

In modern manufacturing and material processing, cutting technologies have evolved significantly, catering to diverse industries’ specific needs. Two prominent cutting methods that have gained widespread popularity are the endless diamond wire saw and the laser cutter. Each technology possesses unique capabilities and advantages, making them suitable for different applications. In this article, we will explore the key differences between the endless diamond wire saw and the laser cutter, shedding light on their respective features, benefits, and ideal use cases.

1,Endless Diamond Wire Saw:

The endless diamond wire saw 500is a cutting-edge tool that utilizes a continuous loop of diamond-impregnated wire to slice through various materials with precision. This technology excels in cutting hard and brittle materials, such as stone, glass, ceramics, and semiconductor wafers. Here are the significant characteristics of the endless diamond wire saw:

a. Precision and Versatility:

Endless diamond wire saws are renowned for their exceptional cutting precision and versatility. They can achieve intricate and complex cuts, making them ideal for applications that require high accuracy, like producing specialized components or intricate shapes for industrial use.

b. Reduced Material Loss:

The thin diamond wire minimizes kerf width, resulting in reduced material wastage. This aspect is particularly valuable when working with expensive or scarce materials, as it optimizes material utilization and reduces production costs.

c. Enhanced Safety:

Endless diamond wire saws generally involve less heat generation during the cutting process compared to some other cutting methods. This aspect minimizes the risk of thermal damage to the material and ensures safety during operation.

d. Brittle Material Handling:

Endless diamond wire saws are particularly well-suited for cutting delicate and brittle materials without causing cracks or damage. This makes them indispensable in industries like electronics, where fragile materials need precise processing.

2,Laser Cutter:

Laser cutters utilize high-intensity laser beams to cut through various materials. This technology is highly versatile and applicable to a wide range of materials, including metal, wood, plastics, fabrics, and more. Let’s explore the defining characteristics of laser cutters:

a. High Speed and Accuracy:

Laser cutters are known for their high cutting speeds and exceptional accuracy. The focused laser beam allows for swift and precise cuts, making them a popular choice for rapid prototyping and high-volume manufacturing.

b. Non-Contact Cutting:

One significant advantage of laser cutters is their non-contact cutting method. The absence of physical contact with the material minimizes wear and tear on cutting tools, reducing maintenance requirements and prolonging the machine’s lifespan.

c. Complex Shapes and Intricate Designs:

Due to their non-contact nature and high precision, laser cutters excel in producing complex shapes and intricate designs. This aspect is advantageous for applications in various industries, such as arts, crafts, and custom manufacturing.

d. Versatility of Materials:

Laser cutters offer unparalleled versatility when it comes to the types of materials they can handle. They can cut through various thicknesses and densities, making them ideal for applications that involve different materials within a single project.

3,Endless Diamond Wire Saw vs. Laser Cutter: Ideal Applications:

The choice between an endless diamond wire saw and a laser cutter depends on the specific requirements of the project and the materials involved. Here are some examples of ideal applications for each technology:

a. Endless Diamond Wire Saw:

- Processing hard and brittle materials like semiconductors, glass, and ceramics.

- Creating precise and intricate shapes for industrial components.

- Cutting large blocks of stone or slabs into thinner slices for construction and monument fabrication.

b. Laser Cutter:

- Rapid prototyping and production of custom designs in various materials.

- Cutting intricate patterns and designs in fabrics and textiles for the fashion industry.

- Precision cutting of metal sheets and foils for industrial applications.

Conclusion:

Both the endless diamond wire saw and the laser cutter are remarkable cutting technologies with distinct advantages and applications. The endless diamond wire saw excels in handling hard and brittle materials, offering enhanced precision and reduced material wastage. On the other hand, the laser cutter boasts high speed, versatility, and non-contact cutting capabilities, making it ideal for various materials and intricate designs. The choice between these cutting methods depends on the specific needs of the project and the materials being processed, ensuring that manufacturers and industries can achieve optimal results with the appropriate cutting technology.