Table of Contents

The Endless Wire Saw Cut Machine: Precision Cutting for Straight Lines and Curves

In the world of manufacturing and materials processing, precision cutting plays a vital role. Among the cutting-edge technologies available, the Endless Wire Saw Cut Machine stands out as a versatile and highly efficient solution. This large vertical cutting equipment is designed to seamlessly cut both straight lines and complex curves, making it an indispensable tool in various industries.

Unraveling the Endless Wire Saw Cut Machine:

At its core, the Endless Wire Saw Cut Machine is a marvel of engineering. This specialized equipment employs a continuous loop of wire, immersed in a cutting fluid, to precisely and consistently cut various materials. What sets it apart is its ability to handle both straight-line cuts and intricate curves with ease.

Precision and Versatility:

One of the standout features of this machine is its unmatched precision. Whether you’re working with silicon wafers, ceramics, glass, or other brittle materials, the Endless Wire Saw Cut Machine ensures minimal material wastage and reduced production costs. Its programmable cutting path allows for high accuracy, making it a preferred choice for industries like semiconductors, solar cells, and optoelectronics, where precision is paramount.

Automation and Efficiency:

The Endless Wire Saw Cut Machine can also be seamlessly integrated into automated production lines, enhancing overall efficiency. This means that once the cutting path is programmed, it can operate independently, reducing the need for constant human intervention and increasing throughput.

A Multitude of Applications:

Its versatility extends beyond the industrial sector. Researchers and innovators often turn to this machine for materials research and prototyping, as its ability to cut various materials and create complex shapes is unmatched.

Maintenance and Safety:

To ensure consistent performance, regular maintenance is essential. Manufacturers typically provide guidelines for wire replacement, upkeep of the cutting fluid system, and general machine maintenance. Moreover, safety precautions, such as wearing protective gear and adhering to operational guidelines, are critical when operating the Endless Wire Saw Cut Machine.

In conclusion, the Endless Wire Saw Cut Machine represents a pinnacle of cutting technology, offering precision, versatility, and efficiency in one package. Its ability to cut both straight lines and curves makes it a top choice for industries requiring high-precision cutting, and its applications continue to expand as innovators explore its capabilities. Whether you are in the semiconductor industry or a materials researcher, this machine is an indispensable tool in the pursuit of precision and excellence.

According to the latest report from the International Federation of Robotics (IFR), automation cutting equipment, such as the Endless Wire Saw Cut Machine, plays a crucial role in modern manufacturing. The IFR is a leading authority in the global robotics field, providing reliable information on automation technologies and robot applications.

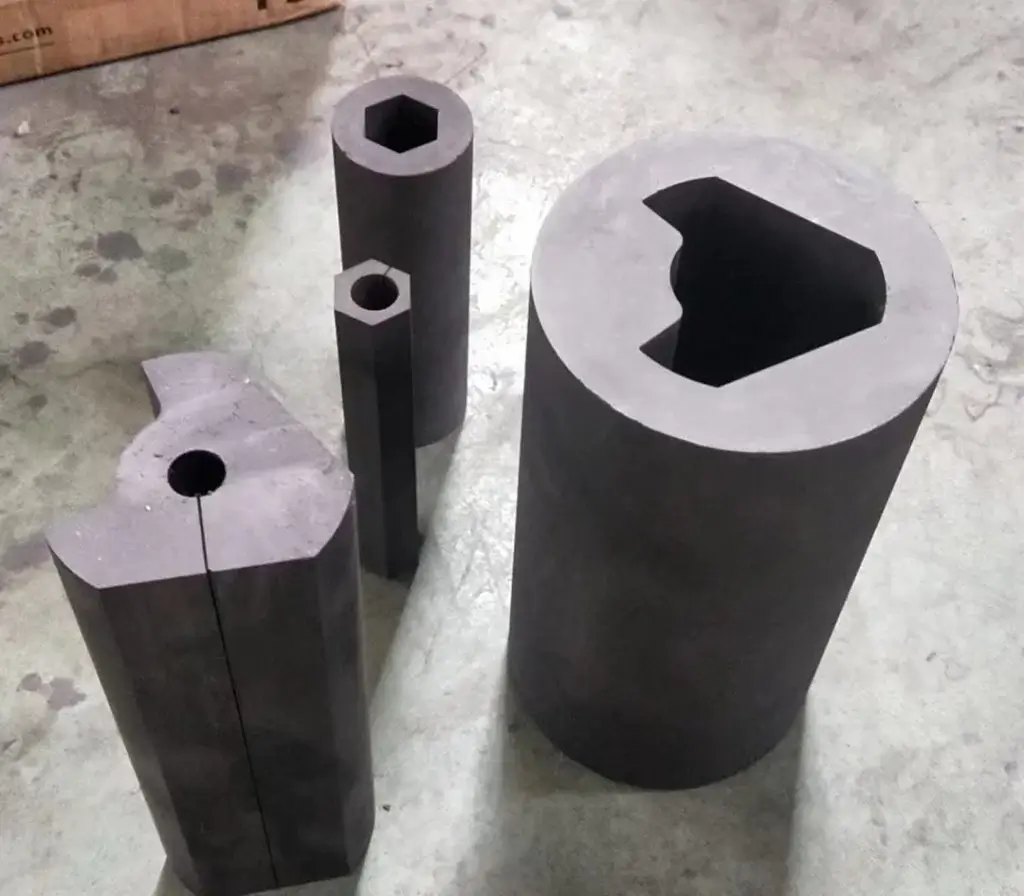

The video records the process of cutting a circular shape on customer’s graphite material.

The Endless Wire Saw Cut Machine

Q:What is an Endless Wire Saw Cut Machine?

An Endless Wire Saw Cut Machine is a precision cutting device commonly used for cutting brittle materials such as silicon wafers, ceramics, and glass. It employs a continuous loop of wire for cutting.

Q:What types of materials can be processed by this cutting system?

A: The Endless Wire Saw Cut Machine is adept at slicing through a wide range of hard materials, such as granite, marble, and reinforced concrete. Its design allows for precise and efficient cutting, making it a versatile tool in various industrial applications.

Q: How does the accuracy of this cutting tool compare to traditional saws?

A: This machine offers superior precision, especially beneficial for intricate designs and detailed architectural projects. The continuous wire movement ensures clean and exact cuts, surpassing many conventional cutting methods.

Q: What safety protocols should be observed when operating this equipment?

A: Operating the Endless Wire Saw Cut Machine requires adherence to strict safety measures. This includes wearing appropriate protective gear, ensuring regular maintenance checks, and adhering to operational guidelines to prevent accidents and ensure safe usage.

Q: What maintenance is needed for the wire in this cutting device?

A: Regular maintenance of the Endless Wire Saw Cut Machine involves monitoring the wire for signs of wear, maintaining optimal tension, and replacing the wire as needed. This ensures consistent cutting efficiency and prolongs the machine’s lifespan.

Q: Is this machine suitable for large-scale industrial projects?

A: Absolutely. The Endless Wire Saw Cut Machine is designed to handle large-scale projects efficiently. Its capability to cut large blocks of material makes it an ideal choice for significant industrial applications.

Q: Can you detail the precision level offered by this machine?

A: The Endless Wire Saw Cut Machine is renowned for its high precision. It is particularly suitable for projects requiring detailed and complex cuts, with the continuous wire movement enabling accurate and clean slicing.

Q: How does this cutting method impact the environment?

A: The environmental impact of the Endless Wire Saw Cut Machine is relatively minimal. Its precision cutting reduces material wastage, and the operation produces less dust and debris than some traditional methods, making it a more eco-friendly option.

Q: Is the Endless Wire Saw Cut Machine capable of slicing through reinforced materials?

A: Yes, the machine can cut through reinforced materials. However, the effectiveness depends on the wire used and the machine’s specifications. It’s crucial to select the appropriate wire type for reinforced materials to ensure efficient and smooth cutting.

Q: What are the power requirements for this cutting machine?

A: The power requirements for the Endless Wire Saw Cut Machine vary based on the model and its intended use. Generally, these machines are designed for industrial applications and may require a significant power supply to operate efficiently.

Q: How does the wire’s speed affect the cutting process?

A: The speed of the wire in the Endless Wire Saw Cut Machine plays a crucial role in the cutting process. Faster wire speeds can increase cutting efficiency but may also wear the wire quicker. It’s essential to balance speed with the material being cut for optimal results.