Tabla de contenido

Introducción

En el ámbito del procesamiento industrial de materiales, la evolución de las tecnologías de corte ha provocado avances notables en diversos sectores. Una innovación que ha acaparado gran atención es la sierra de hilo de diamante sin fin, una herramienta revolucionaria que ha redefinido el corte de precisión. En el ámbito del procesamiento del grafito, esta tecnología de vanguardia brilla con luz propia, ofreciendo ventajas incomparables sobre los métodos convencionales. Este artículo explora las aplicaciones y ventajas de la cortadora de hilo de diamante sinfín de Shine Wire Cut en el corte de grafito y subraya que es la mejor opción para el corte industrial moderno.

La maravilla de la tecnología de sierras de hilo diamantado sin fin

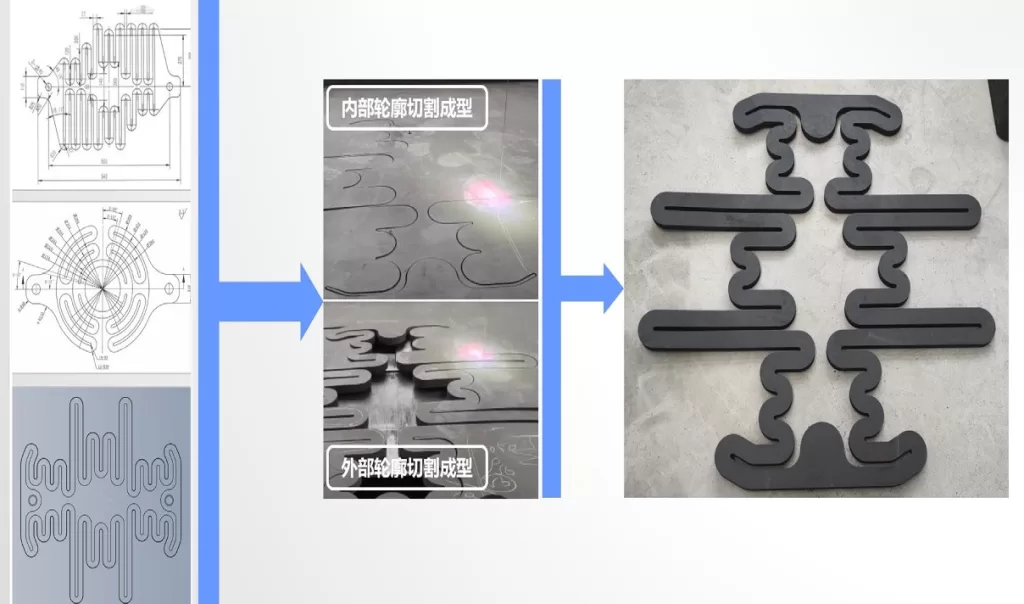

Las sierras de hilo de diamante sin fin han metamorfoseado el paisaje del corte con su bucle continuo de hilo impregnado de diamante, demostrando el poder de los diamantes en el corte de materiales duros con una precisión sin precedentes. Las sierras de hilo de diamante sin fin de Shine Wire Cut encarnan esta innovación, presentando un cambio de paradigma en el procesamiento del grafito que desbloquea nuevos niveles de eficiencia, precisión y versatilidad.

El futuro del tratamiento del grafito

El grafito, conocido por sus propiedades únicas de alta conductividad térmica, resistencia eléctrica y resistencia mecánica, es un material crucial en diversas industrias. Las sierras de hilo de diamante sinfín de Shine Wire Cut están preparadas para redefinir el procesamiento del grafito en aplicaciones clave:

Mecanizado de precisión:

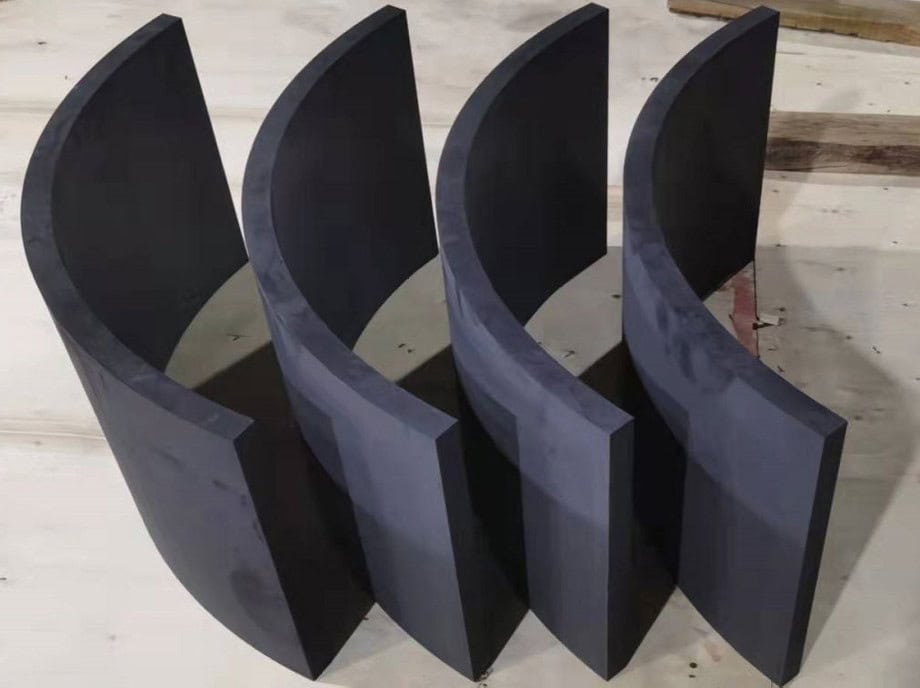

El grafito desempeña un papel vital en los sectores aeroespacial y automovilístico, donde los componentes intrincados exigen un mecanizado de precisión. Las cortadoras de hilo de diamante sinfín de Shine Wire Cut ofrecen una precisión inigualable, cortando grafito con un desperdicio mínimo de material y una generación de calor insignificante. Esto se traduce en componentes con geometrías intrincadas y acabados superficiales superiores, elevando la calidad general del producto.

Producción de moldes y matrices:

En industrias como la fundición y el moldeo por inyección, la creación de moldes y matrices exige precisión y durabilidad. Las sierras de hilo de diamante sinfín brillan en este campo, ya que permiten dar forma al grafito con precisión y eficacia para crear moldes con detalles intrincados y superficies lisas. Los moldes resultantes no sólo mejoran la eficacia de la producción, sino que también proporcionan productos finales de mayor calidad.

Fabricación de semiconductores:

El grafito es un material crítico en la fabricación de semiconductores, donde la precisión y la pureza son primordiales. Las sierras de hilo de diamante sinfín de Shine Wire Cut garantizan una contaminación mínima durante el corte, lo que da lugar a sustratos, soportes de obleas y otros componentes que cumplen las estrictas exigencias de la industria de semiconductores.

Ventajas de la sierra de hilo diamantado sin fin de Shine Wire Cut en el corte de grafito

Precisión excepcional:

La acción de corte continuo de la cortadora de hilo de diamante sin fin de Shine Wire Cut garantiza cortes precisos, incluso para formas complejas y diseños intrincados. Esta precisión se traduce en componentes que encajan a la perfección en los ensamblajes, lo que reduce los requisitos de posprocesamiento.

Pérdida de material minimizada:

Las sierras de hilo de diamante sin fin minimizan el desperdicio de material gracias a sus finos hilos de diamante y a su reducida anchura de corte. La tecnología de Shine Wire Cut optimiza la utilización del grafito, contribuyendo al ahorro de costes y a la sostenibilidad.

Reducción del impacto térmico:

Los métodos de corte tradicionales suelen generar un calor excesivo que afecta a las propiedades del material. Las sierras de hilo de diamante sin fin de Shine Wire Cut producen un calor mínimo durante el corte, preservando las características únicas del grafito.

Versatilidad en todos los grados:

El grafito existe en varios grados, cada uno con propiedades distintas. Las sierras de hilo de diamante sinfín de Shine Wire Cut se adaptan perfectamente a los distintos grados de grafito, demostrando su versatilidad y adaptabilidad.

Mayor productividad:

El movimiento de corte continuo de las cortadoras de hilo de diamante sinfín de Shine Wire Cut aumenta la productividad al permitir un procesamiento eficaz e ininterrumpido. Esto acorta los ciclos de producción y acelera la finalización de los proyectos.

Pioneros en el corte de grafito

Shine Wire Cut's sierra de hilo diamantado sin finrepresentan la cúspide de la innovación en el corte de grafito. Gracias a su excepcional precisión, la minimización del desperdicio de material, la reducción del impacto térmico, la versatilidad y la mejora de la productividad, estas herramientas de vanguardia trascienden los métodos de corte tradicionales. El procesamiento del grafito ya no está sujeto a las limitaciones convencionales, sino que está preparado para explorar nuevas fronteras de eficacia y calidad.

Conclusión

En el panorama en constante evolución del corte industrial, las sierras de hilo diamantado sinfín de Shine Wire Cut brillan como el faro del avance. Gracias a su inigualable precisión, eficacia y adaptabilidad, han redefinido el procesamiento del grafito en todas las industrias. A medida que el mundo del grafito se adentra en una nueva era de innovación y excelencia, las cortadoras de hilo de diamante sinfín de Shine Wire Cut son la luz que guía el camino, dando forma al presente y al futuro del corte de grafito con precisión y brillantez.