Palabras clave: corte por ultrasonidos, corte con hilo de diamante anular, tecnologías de corte de precisión, tratamiento de materiales

Tabla de contenido

Introducción

El panorama de la fabricación sigue siendo remodelado por tecnologías de vanguardia que prometen precisión, eficacia y versatilidad. En este artículo, nos embarcamos en un viaje de exploración de dos tecnologías de corte extraordinarias: el corte por ultrasonidos y el innovador corte con hilo de diamante cerrado. Profundizaremos en los detalles de estas tecnologías, sus aplicaciones y el impacto que están teniendo en el procesamiento moderno de materiales.

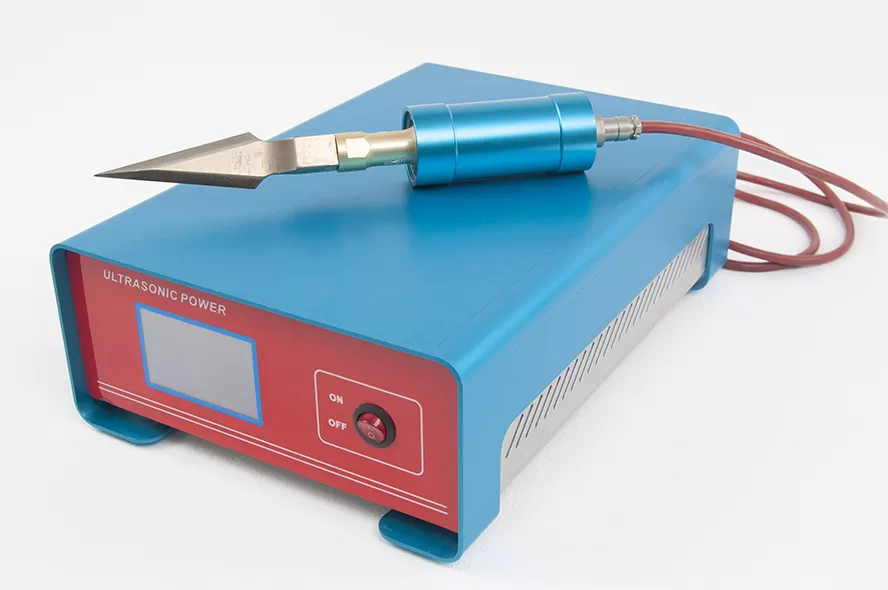

Corte por ultrasonidos: Precisión en las vibraciones

El corte por ultrasonidos es una técnica que emplea vibraciones de alta frecuencia para lograr cortes increíblemente precisos en diversos materiales. Es un método que ofrece toda una serie de ventajas.

Principio de funcionamiento:

El corte por ultrasonidos funciona según el principio de convertir energía eléctrica de alta frecuencia en vibraciones mecánicas. Una cuchilla o bocina, que vibra a frecuencias normalmente superiores a 20.000 Hz, crea un rápido movimiento de vaivén que le permite cortar materiales con gran precisión.

Ventajas:

- Precisión submilimétrica: El corte por ultrasonidos ofrece un nivel de precisión sin precedentes, con cortes que alcanzan una exactitud submilimétrica. Por eso es ideal para aplicaciones en las que la precisión es primordial.

- Cortes limpios: La ausencia de calor en el proceso de corte significa que no hay fusión ni deformación del material. El resultado son cortes limpios y afilados que requieren un procesamiento posterior mínimo o nulo.

- Versatilidad de materiales: El corte por ultrasonidos puede aplicarse a una amplia gama de materiales, desde plásticos y caucho hasta productos alimentarios delicados, textiles e incluso compuestos.

- Reducción de los residuos materiales: La naturaleza precisa del corte por ultrasonidos reduce el desperdicio de material, lo que contribuye a unas prácticas de fabricación más sostenibles.

Desventajas:

- Espesor de corte limitado: El corte por ultrasonidos es más eficaz para materiales de grosor moderado. Para materiales muy gruesos, podrían ser más adecuados otros métodos de corte.

- Inversión inicial: Los equipos de corte por ultrasonidos pueden ser costosos de adquirir y montar.

Aplicaciones:

- Industria alimentaria: El corte por ultrasonidos se utiliza para cortar con precisión tartas, productos de panadería y otros productos alimentarios.

- Industria electrónica: Encuentra aplicaciones en el corte de sustratos delicados en el sector de la electrónica.

Corte con hilo de diamante cerrado: Una revolución en precisión

Por el contrario, corte con hilo de diamante cerrado es una tecnología relativamente reciente en el campo del corte de precisión. Esta tecnología emplea un hilo ultrafino incrustado con partículas microscópicas de diamante para cortar diversos materiales, tanto conductores como no conductores. Está causando sensación en varias industrias.

Principio de funcionamiento:

Hilo diamantado cerrado utiliza un hilo fino incrustado con partículas microscópicas de diamante. Este hilo es guiado a través del material, y la naturaleza abrasiva de las partículas de diamante permite un corte preciso.

Ventajas:

- Versatilidad de materiales: El corte con hilo de diamante anular destaca por su capacidad para cortar tanto materiales conductores como no conductores, ofreciendo una gama de aplicaciones inigualable.

- Eficacia inigualable: Este método ofrece velocidades de corte superiores a las de los métodos convencionales, con una mayor adaptabilidad a diversos tamaños de material, lo que mejora significativamente la eficacia del proceso de corte.

- Reducción de los residuos materiales: El proceso destaca por la reducción de residuos de material, lo que lo convierte en una opción responsable con el medio ambiente.

Aplicaciones:

- Fabricación de semiconductores: Su precisión y mínimo desperdicio son inestimables en la producción de componentes semiconductores.

- Conformación de vidrio óptico: Esta tecnología se utiliza para dar forma a componentes de equipos ópticos que requieren gran precisión.

- Producción de células solares: El corte con hilo diamantado anular se aplica al corte de obleas finas de silicio en la producción de células solares.

Perspectivas de futuro

En el mundo en constante evolución de la fabricación y el procesamiento de materiales, la búsqueda de precisión y eficacia es incesante. El corte por ultrasonidos y el corte con hilo de diamante en anillo surgen como poderosos contendientes, cada uno con sus capacidades únicas. A medida que estas tecnologías sigan avanzando y adaptándose, desempeñarán un papel fundamental en la configuración del futuro de la fabricación, ofreciendo soluciones que satisfagan a las industrias que requieren precisión y un desperdicio mínimo. Tanto si se trata de los delicados cortes que permite el corte por ultrasonidos como de la versatilidad del corte con hilo de diamante en anillo, estos métodos están redefiniendo los límites de la precisión en el procesamiento de materiales.