Wire saw cutting technology is a unique device that effectively cuts different substances. It uses a wire, generally covered with diamond or any other strong material, to make precise cuts. The taper design allows the saw to cut through diverse shapes and sizes. This tool may be very beneficial if you’re in industries like creation, manufacturing, or jewelry making. But did you recognize there are distinctive varieties of 3D wire saw applications? Let’s check the available types and see how they could assist in distinct duties.

Different Types Of 3d Taper Cut Wire Saw

Manual 3-D Taper Cut Wire Saw

The manual 3D taper-cutting wire saw is a simple gadget version. It’s typically smaller and requires more significant effort from the operator to make specific cuts. You control the device by hand, meaning you have complete control over the route and speed of the cut. This kind is ideal for smaller projects where the first-class element is essential, such as in art and jewelry paintings.

Automatic 3D Taper Cut Wire Saw

An automatic 3-D taper cut wire saw is powered by energy and doesn’t need as much guide work. It can cut much faster and with greater precision than a manual saw. These machines are programmable, meaning you may set precise instructions, and the device will observe them without having you guide it all the time.

This type is ideal for industries in which time is critical, like manufacturing. Since it operates independently, the automated 3-D taper cutting wire saw is best for large-scale tasks with critical accuracy and velocity.

CNC 3-D Taper Cut Wire Saw

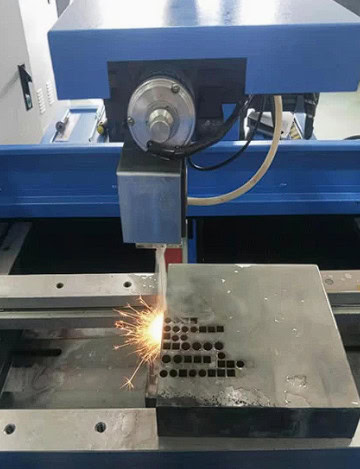

CNC stands for Computer Numerical Control. This type of 3D taper cutting wire saw is the most superior. It uses a computer to manipulate the slicing process. The machine is pre-programmed with precise commands, allowing for exact and specific cuts. CNC 3-D taper cutting wire saws are frequently used in aerospace, automotive, and architecture industries.

One of the most important blessings of this type is its capacity to deal with complicated designs without problems. A CNC wire saw is a satisfactory option if you have an undertaking that calls for a lot of precision and wants to make genuine cuts.

Waterjet-Assisted 3-D Taper Cut Wire Saw

This type of wire saw combines the power of waterjet technology with wire slicing. It uses high-strain water circulation at the side of the wire to make very easy cuts. Waterjet-assisted wire saws slice substances that are sensitive to heat, such as solid metals and plastics.

The water cools the fabric as it cuts, stopping damage or warping. This type is perfect for industries that must preserve the material’s temperature stability throughout the reduction process.

Portable 3D Taper Cut Wire Saw

A transportable 3D taper-cut wire saw is small and lightweight. It’s designed to move around smoothly, making it ideal for on-site jobs. Construction workers frequently use transportable wire saws to slice through stone, concrete, or steel after they want to move from one area to another.

Where Can I Buy a 3-D Taper Cut Wire Saw Machine?

If you want to buy a diamond wire cutting saw deviceEl Shine Smart Equipment Industry is a super place to start. They are regarded for his or her remarkable machines and outstanding customer support. Shine Smart offers a variety of models to fit your particular needs. Whether you are running on small initiatives or massive-scale manufacturing, they have options that can help. Their reliable CNC taper cut wire saw offers a guide that will help you make the proper desire. You can visit their website or contact them immediately to research their offerings.

What is the Best 3D Taper Cut Wire Saw Machine?

Regarding the tremendous 3D taper cutting wire saw machinesEl SVT 60-60 sticks out. This gadget is praised for its precision and performance. It is designed to address various substances, making it a versatile desire for distinctive industries. The SVT 60-60 is person-friendly, which means even beginners can operate it readily. Its superior functions allow for clean and correct cuts, saving time and effort.

Preguntas frecuentes

What is a 3D taper cut wire saw?

A precision wire saw machine saw is a device that uses a wire to make specific cuts in substances like metal, stone, or timber. It is used in many industries to reduce distinct shapes and designs.

What is the difference between a manual and automatic 3-D taper cut wire saw?

A manual wire saw requires hand manipulation, while an automated saw is powered by electricity and might follow programmed commands. Automated wire saw systems are faster and more unique, but manual saws are inexpensive and better for small projects.

Can a 3-D taper-cut wire saw cut through any fabric?

Yes, depending on the type of wire and the system’s strength. Some fashions can be cut through metal, stone, timber, and plastic. Special saws like the waterjet-assisted kind can even cut warm-touchy materials without harming them.

En resumen

Depending on your desires, one-of-a-kind Sierras de hilo de corte cónico 3D will be available. Whether you need a manual saw for the best information or a CNC machine for exact cuts, a wire saw is suitable. Automatic and waterjet-assisted saws provide more velocity and precision, even as portable saws offer flexibility on process websites. Knowing the kinds of 3D taper-cutting wire saws lets you make the quality choice for your projects.