¿Está buscando un Máquina cortadora de alambre en venta ¿pero se siente abrumado por la multitud de opciones disponibles? No tema, esta guía esencial le orientará en la dirección correcta. Cuando se trata de elegir el máquina cortadora de alambreEn cualquier caso, es fundamental tener en cuenta varios factores para tomar una decisión bien informada que satisfaga sus necesidades específicas.

Cómo elegir la máquina cortadora de alambre adecuada para la venta

Lo primero y más importante es conocer sus necesidades de corte. Antes de sumergirse en el mundo de las máquinas de corte de alambre, dedique un momento a evaluar el tipo de materiales con los que va a trabajar, el grosor de los alambres y el volumen que es necesario cortar. Este paso inicial le ayudará a determinar la capacidad de corte necesaria para sus proyectos.

A continuación, profundicemos en los distintos tipos de cortadoras de hilo disponibles. Desde las máquinas manuales que ofrecen un control práctico hasta los modelos semiautomáticos y automáticos que proporcionan una mayor eficacia, cada tipo viene con su propio conjunto de características, ventajas y limitaciones. Tenga en cuenta su flujo de trabajo y sus requisitos de producción para elegir la opción más adecuada.

A la hora de elegir una cortadora de hilo, la calidad y la precisión deben ser sus prioridades. Invertir en una máquina con una construcción de calidad y capacidades de corte precisas garantizará operaciones fluidas y precisas, mejorando en última instancia la eficiencia de sus proyectos.

Por supuesto, el presupuesto desempeña un papel importante en cualquier decisión de compra. Sin embargo, esto no significa que tenga que sacrificar la calidad por la rentabilidad. Explore opciones económicas que ofrezcan un equilibrio entre asequibilidad y rendimiento, teniendo en cuenta el ahorro a largo plazo y el rendimiento de la inversión.

Antes de tomar una decisión definitiva, no olvide investigar la reputación de la marca y los comentarios de los clientes. Elegir una marca reputada con comentarios positivos de los clientes puede proporcionarle confianza en la fiabilidad y satisfacción de la cortadora de hilo elegida.

Por último, tenga en cuenta las características y accesorios adicionales que pueden mejorar la funcionalidad de su cortadora de hilo. Desde enderezadoras de alambre hasta contadores y protectores de seguridad, estos extras pueden mejorar la facilidad de uso y la eficiencia en sus operaciones de corte.

Tabla de contenido

Conozca sus necesidades de corte

A la hora de elegir la máquina de corte de alambre adecuada, es fundamental conocer sus necesidades de corte. Evaluar el tipo de materiales, el grosor y el volumen de alambre que necesita cortar le ayudará a determinar la máquina más adecuada para sus requisitos específicos.

Tenga en cuenta los siguientes factores para asegurarse de elegir una cortadora de hilo que satisfaga sus necesidades:

- Material: Determine el tipo de material que va a cortar, ya sea cobre, aluminio, acero u otros metales.

- Grosor: Tenga en cuenta el grosor del alambre con el que va a trabajar, ya que las distintas máquinas tienen distintas capacidades de corte.

- Volumen: Evalúe el volumen de alambre que necesita cortar regularmente para determinar la capacidad de carga de trabajo de la máquina.

Analizando estos aspectos, podrá reducir eficazmente sus opciones y elegir una cortadora de hilo que se ajuste a sus necesidades de corte. Tanto si se trata de un pequeño aficionado como de una operación industrial a gran escala, encontrar la máquina adecuada es esencial para un corte de alambre eficiente y preciso.

Tipos de cortadoras de hilo

A la hora de elegir la cortadora de hilo que mejor se adapte a sus necesidades, es fundamental conocer los distintos tipos disponibles. Las máquinas de corte de hilo están disponibles en diferentes modelos, cada uno de los cuales ofrece características y capacidades únicas para satisfacer requisitos de corte específicos. Profundicemos en los distintos tipos de cortadoras de hilo para ayudarle a tomar una decisión informada:

- Máquinas manuales de corte de alambre: Estas máquinas requieren un funcionamiento manual, en el que el usuario controla el proceso de corte. Las cortadoras de hilo manuales son adecuadas para operaciones a pequeña escala y ofrecen una solución rentable para las necesidades básicas de corte.

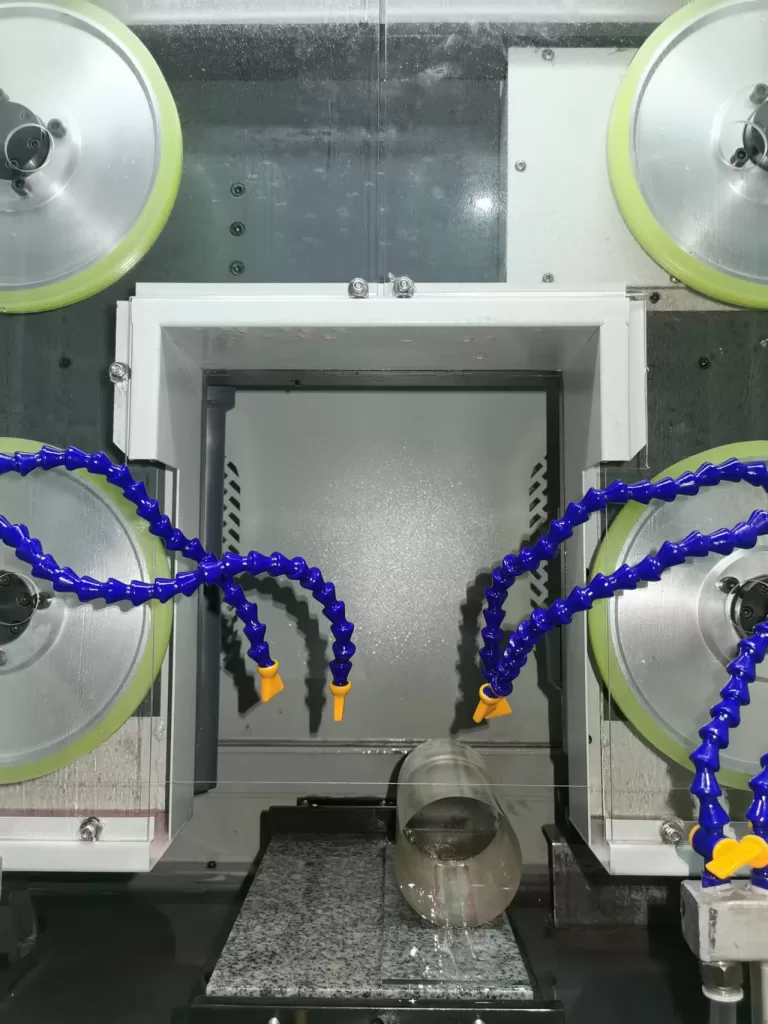

- Cortadoras de hilo semiautomáticas: Las cortadoras de hilo semiautomáticas, que combinan el control manual con funciones automatizadas, ofrecen un equilibrio entre la intervención del usuario y la precisión de la máquina. Estas máquinas son ideales para proyectos de tamaño medio que requieren una precisión de corte constante.

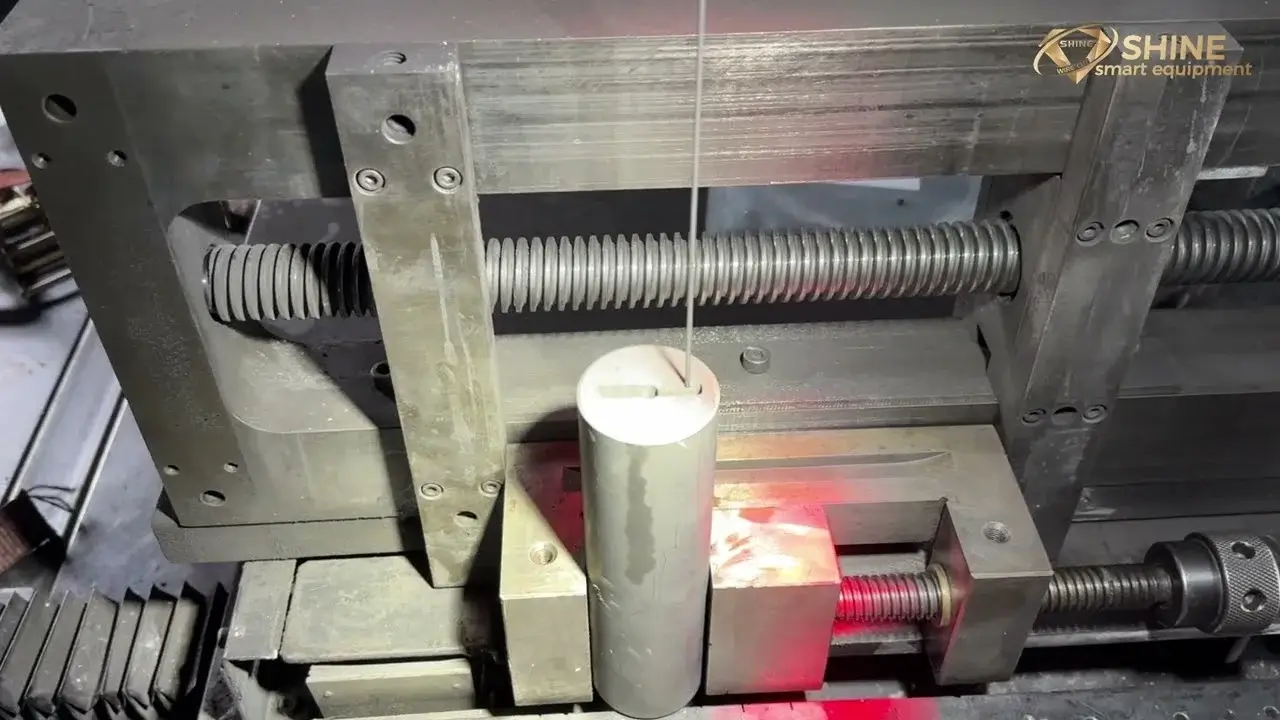

- Máquinas automáticas de corte de alambre: Totalmente automatizadas, estas máquinas son capaces de realizar tareas de corte de forma independiente una vez configuradas. Las máquinas automáticas de corte de alambre están diseñadas para entornos de producción de gran volumen en los que la eficiencia y la velocidad son primordiales.

Cada tipo de máquina de corte de alambre tiene sus ventajas y limitaciones, por lo que es esencial evaluar sus necesidades de corte y requisitos de producción antes de hacer una elección. Tenga en cuenta factores como el volumen de alambre a cortar, el nivel de precisión necesario y la eficacia general de la máquina en su aplicación específica.

Factores a considerar antes de la compra

Si está pensando en comprar un Máquina cortadora de alambre en ventaSin embargo, hay varios factores cruciales que debe tener en cuenta para tomar la decisión correcta. Profundicemos en los aspectos clave que deben influir en su decisión:

- Reputación de marca: La marca de la cortadora de hilo desempeña un papel importante a la hora de determinar su calidad y fiabilidad. Optar por una marca de renombre como Brille puede ofrecer la garantía de una máquina bien construida y duradera.

- Velocidad y precisión de corte: Evalúe la velocidad de corte y la precisión de la máquina, ya que estos factores repercuten directamente en la eficacia de sus operaciones. Una máquina que ofrezca alta precisión y corte rápido puede mejorar la productividad.

- Requisitos de mantenimiento: Tenga en cuenta las necesidades de mantenimiento de la cortadora de hilo. Elija un modelo fácil de mantener para evitar averías frecuentes y garantizar un rendimiento constante.

- Características de seguridad: Dé prioridad a elementos de seguridad como botones de parada de emergencia, protecciones y mecanismos de desconexión automática para salvaguardar a los operarios durante el uso.

- Compatibilidad: Asegúrese de que la cortadora de hilo es compatible con una gran variedad de tipos y grosores de hilo para satisfacer sus diversas necesidades de corte.

Si evalúa detenidamente estos factores, podrá tomar una decisión informada a la hora de seleccionar una máquina de corte por hilo que se ajuste a sus necesidades y ofrezca un rendimiento óptimo. Recuerde que invertir en una máquina de calidad puede reportarle beneficios y eficiencia operativa a largo plazo.

Calidad y precisión

Cuando se trata de seleccionar una máquina de corte de alambre para la venta, son factores primordiales a considerar. La marca Brille ofrece una gama de máquinas de vanguardia que sobresalen en la realización de cortes precisos y de alta calidad para diversas aplicaciones de corte de alambre.

Un aspecto clave que hay que buscar en una cortadora de hilo es la calidad de construcción. Una máquina robusta y duradera como las que ofrece Brille garantiza una fiabilidad a largo plazo y un rendimiento constante. Las capacidades de corte de precisión son esenciales para lograr resultados exactos, especialmente cuando se trabaja con diseños de alambre delicados o intrincados.

Para garantizar el máximo nivel de calidad y precisión, Brille están equipadas con avanzados mecanismos de corte que garantizan cortes limpios y afilados en todo momento. Tanto si corta alambres finos como cables gruesos, estas máquinas están diseñadas para satisfacer los requisitos de corte más exigentes con precisión y eficacia.

Además, Brille están diseñadas para proporcionar velocidades de corte óptimas sin comprometer la precisión. Este equilibrio entre velocidad y precisión es crucial para maximizar la productividad y lograr resultados uniformes en sus proyectos de corte de hilo.

Además, la sencilla interfaz de Brille permiten un manejo y control sencillos, garantizando que incluso las tareas de corte más complejas puedan realizarse con facilidad. El diseño intuitivo y las características ergonómicas de estas máquinas mejoran la experiencia del usuario y contribuyen a la eficiencia general en las operaciones de corte de alambre.

Invertir en un Brille no sólo le garantiza calidad y precisión, sino que también le ofrece un valor a largo plazo por su dinero. Estas máquinas están construidas para durar y requieren un mantenimiento y una conservación mínimos, lo que se traduce en un ahorro de costes a largo plazo.

En conclusión, a la hora de elegir una cortadora de hilo en venta, es esencial dar prioridad a la calidad y la precisión para garantizar un rendimiento y una eficacia óptimos en sus operaciones de corte de hilo. Con Brille puede confiar en la calidad superior y la ingeniería de precisión que las distinguen en el sector.

Opciones asequibles

Este artículo ofrece una guía completa para ayudarle a seleccionar la cortadora de hilo más adecuada a sus necesidades, teniendo en cuenta factores como la capacidad de corte, la precisión, la durabilidad y la rentabilidad.

Cuando busque económico máquinas cortadoras de alambre, la Brille ofrece una gama de opciones que proporcionan un rendimiento de calidad sin arruinarse. Estas son algunas consideraciones clave a tener en cuenta:

- Modelos rentables: Las cortadoras de hilo Shine son conocidas por su precio asequible sin comprometer la calidad. Puede encontrar modelos que se ajustan a su presupuesto al tiempo que ofrecen capacidades de corte fiables.

- Ahorro a largo plazo: Invertir en una máquina de corte de alambre económica de Shine puede suponer un ahorro a largo plazo. Estas máquinas están diseñadas para ser duraderas y eficientes, ofreciendo una solución rentable para sus necesidades de corte.

- Retorno de la inversión: Si elige una cortadora de hilo Shine que se ajuste a su presupuesto, puede esperar un importante retorno de la inversión. Estas máquinas están fabricadas para durar y ofrecer un buen rendimiento, lo que garantiza que su inversión se amortice con el tiempo.

A la hora de considerar opciones económicas, es importante dar prioridad tanto a la asequibilidad como a la calidad. Las cortadoras de hilo Shine logran el equilibrio perfecto, lo que las convierte en una opción excelente para quienes buscan ahorrar dinero sin renunciar al rendimiento.

Reputación de marca y opiniones de clientes

A la hora de elegir la cortadora de hilo adecuada para su venta, la reputación de la marca y las opiniones de los clientes desempeñan un papel crucial para garantizar la calidad y fiabilidad de su compra. La marca "Shine" destaca en el mercado por sus excepcionales cortadoras de hilo que combinan precisión, durabilidad y rentabilidad.

Antes de tomar una decisión, es esencial investigar la reputación de Shine en el sector y explorar las opiniones de los clientes para calibrar los niveles de satisfacción y los comentarios sobre el rendimiento. Al dar prioridad a la reputación de la marca, puede obtener información sobre la calidad general y la fiabilidad de las cortadoras de hilo Shine.

Una de las principales ventajas de elegir Shine como proveedor de máquinas de corte por hilo es el compromiso de la marca con la satisfacción del cliente y la mejora continua. La dedicación de Shine a la innovación y su enfoque centrado en el cliente garantizan que sus productos cumplan los más altos estándares de rendimiento y fiabilidad.

Los comentarios de los clientes sobre las máquinas de corte de alambre Shine suelen destacar la precisión de corte superior, la facilidad de uso y la durabilidad a largo plazo de los equipos. Los comentarios positivos de clientes satisfechos pueden darle confianza en la calidad y el rendimiento de las cortadoras de hilo Shine.

Si tiene en cuenta la reputación de la marca y las opiniones de los clientes, podrá tomar una decisión informada a la hora de comprar una cortadora de hilo en venta. La sólida presencia de Shine en el mercado y los comentarios positivos de los clientes la convierten en una opción fiable para quienes buscan una solución de corte de alambre eficiente y de alta calidad.

Características adicionales y accesorios

Cuando se busca una cortadora de hilo en venta, es esencial tener en cuenta las características y accesorios adicionales que pueden mejorar la funcionalidad y facilidad de uso del equipo. Una marca destacada conocida por su calidad e innovación en máquinas de corte por hilo es Shine. Si explora las funciones y accesorios adicionales que ofrece Shine, podrá optimizar sus operaciones de corte de alambre para obtener eficiencia y precisión.

Algunas de las características adicionales que Shine proporciona con sus máquinas de corte de alambre incluyen:

- Enderezadores de alambre: Garantizan que el alambre esté correctamente alineado antes del corte, lo que da como resultado cortes precisos y limpios.

- Contadores: Llevan la cuenta del número de cables cortados, lo que le ayuda a controlar la productividad y a gestionar el inventario con eficacia.

- Protectores de seguridad: Protegen a los operarios de posibles peligros durante el proceso de corte, dando prioridad a la seguridad en el lugar de trabajo.

Estos accesorios no sólo mejoran el rendimiento de la cortadora de hilo, sino que también contribuyen a la seguridad general y a la eficacia de sus operaciones. El compromiso de Shine con la calidad y la satisfacción del cliente se refleja en el cuidado diseño de estas características adicionales, lo que las convierte en valiosas adiciones a su configuración de corte de hilo.

Preguntas frecuentes

- P: ¿Qué factores debo tener en cuenta al elegir una cortadora de hilo?R: Al seleccionar una máquina de corte de alambre, es esencial tener en cuenta factores como la capacidad de corte, la precisión, la durabilidad, la velocidad de corte, la exactitud, los requisitos de mantenimiento, las características de seguridad y la compatibilidad con distintos tipos de alambre para asegurarse de que satisface sus necesidades específicas.

- P: ¿Cuáles son los distintos tipos de cortadoras de hilo disponibles?R: Existen varios tipos de máquinas cortadoras de alambre: manuales, semiautomáticas y automáticas. Cada tipo tiene sus propias características, ventajas y limitaciones, por lo que es importante entender las diferencias para elegir el que mejor se adapte a sus necesidades.

- P: ¿Qué importancia tienen la calidad y la precisión de una cortadora de hilo?R: La calidad de construcción y la capacidad de corte de precisión son cruciales para que las operaciones de corte de alambre sean eficaces y precisas. Invertir en una máquina con componentes de alta calidad y mecanismos de corte precisos puede repercutir significativamente en el resultado de sus proyectos.

- P: ¿Existen opciones económicas para las máquinas de corte por hilo?R: Sí, hay máquinas de corte de alambre rentables que ofrecen calidad y rendimiento sin arruinarse. Es importante tener en cuenta el ahorro a largo plazo y el retorno de la inversión a la hora de elegir una máquina que se ajuste a su presupuesto.

- P: ¿Cómo puedo garantizar la fiabilidad de una marca de máquina cortadora de hilo?R: Investigar marcas reputadas, leer opiniones de clientes y buscar recomendaciones de expertos del sector puede ayudarle a calibrar la fiabilidad y la satisfacción de los clientes asociadas a una marca concreta de máquinas de corte por hilo.

- P: ¿Qué características y accesorios adicionales debo buscar en una cortadora de hilo?R: Al seleccionar una máquina de corte de hilo, tenga en cuenta la disponibilidad de funciones y accesorios adicionales, como enderezadoras de hilo, contadores y protecciones de seguridad. Estos componentes adicionales pueden mejorar la funcionalidad y facilidad de uso de la máquina para sus necesidades específicas.