Table of Contents

Introduction

In the vast landscape of manufacturing and construction, cutting equipment plays a pivotal role in shaping materials into final products. From heavy-duty industrial machines to precision tools, the variety of cut machine available today is as diverse as the materials they process. This guide delves into the world of cut machine, exploring its different forms and functions.

Understanding Cutting Equipment

Cut machine refers to tools and machines designed to cut, shape, or remove material from a workpiece. This broad category includes everything from hand tools to sophisticated computer-controlled machines, each serving specific purposes in various industries such as manufacturing, construction, woodworking, and metalworking.

Types of Cutting Equipment

1. Mechanical Cutting Tools

- Saws: From handheld saws to large band saws and circular saws, these are fundamental in woodworking and metalworking.

- Shears: Used for cutting sheet metal, shears are essential in metal fabrication.

- Lathes: Although primarily used for shaping, lathes can also perform cutting operations in metalworking and woodworking.

2. Thermal Cutting Equipment

- Oxy-Fuel Cutting Torches: These torches use a combination of fuel gases and oxygen to cut through metal, commonly used in industrial fabrication.

- Plasma Cutters: Ideal for cutting metal, plasma cutters offer speed and precision and are used in various industrial applications.

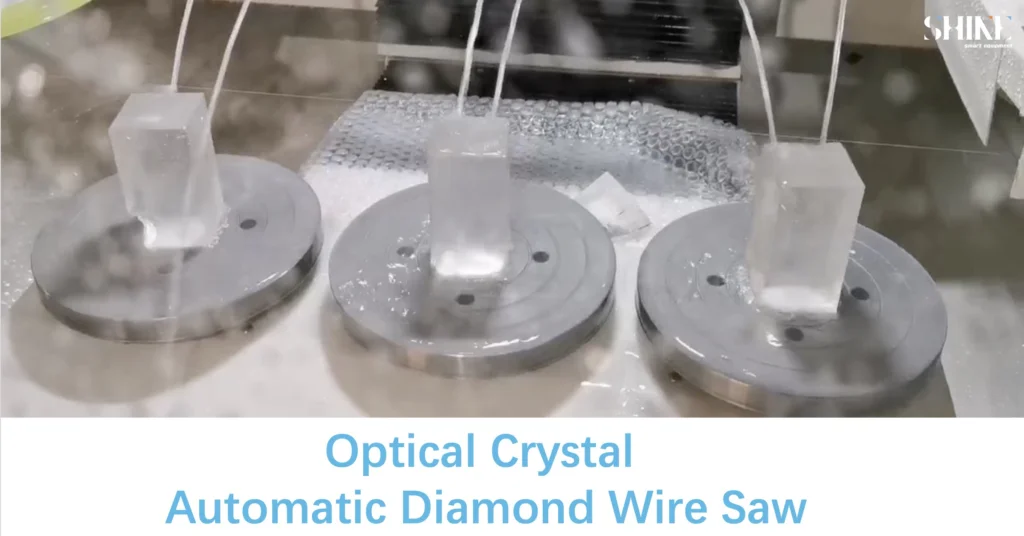

3. endless diamond wire cutting equipment

4,Abrasive Cutting Tools

- Grinders: Grinders use an abrasive wheel to cut and finish metals and other materials.

- Water Jet Cutters: Utilizing high-pressure water, often with added abrasives, water jet cutters can slice through a variety of materials, including metal, stone, and glass.

- Diamond Wire cut: use a steel wire coated with diamond grains to cut materials.

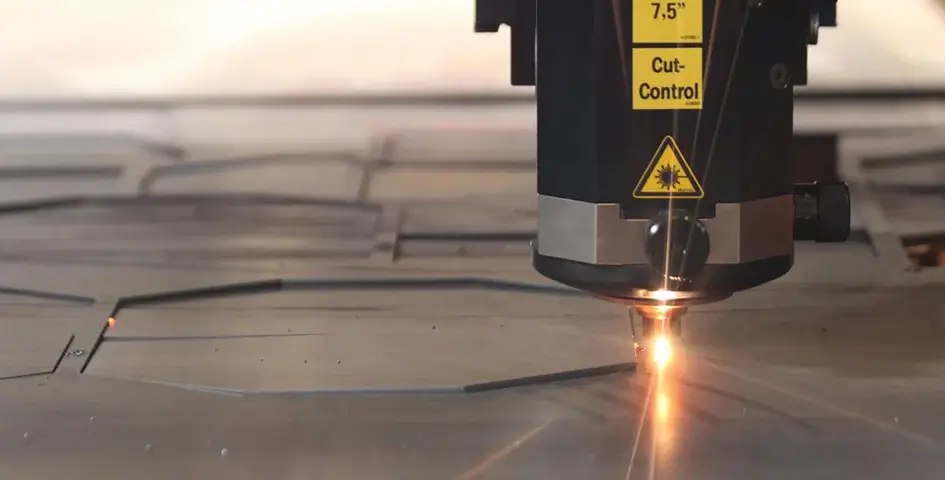

4. Laser Cutting Machines

- Laser Cutters: These machines use a high-powered laser beam to cut materials like metal, plastic, and wood. They are renowned for their precision and are widely used in industries requiring detailed and intricate cutting.

5. Electron Beam and Ion Cutting Tools

- Electron Beam Machines: Employed primarily in specialized industrial applications, these machines use a focused beam of electrons to cut materials.

- Ion Cutting Equipment: Similar to electron beam machines, ion cutting tools use ionized gas to perform cutting tasks, though they are less common.

The Role of Cut machine in Manufacturing

Precision and Efficiency

- Cutting machine is essential for achieving precision and efficiency in manufacturing. From creating intricate parts in aerospace to basic components in everyday appliances, these tools ensure accuracy and consistency.

Material Flexibility

- With a range of cut machine available, manufacturers can process a wide array of materials, from metals and woods to composites and plastics.

Cost-Effectiveness

- By reducing material waste and improving production speed, cut machine helps manufacturers minimize costs and increase profitability.

Innovations in Cutting machine Technology

Technological advancements have significantly transformed cut machine, making it more efficient, precise, and versatile.

CNC Technology

- Computer Numerical Control (CNC) technology in cutting machine has revolutionized precision machining, allowing for automation and high accuracy.

Laser and Plasma Technology

- The development of laser and plasma cut equipment has provided industries with tools for high-precision and high-speed cutting, essential in complex manufacturing processes.

Applications of Cutting Equipment Across Industries

Construction

- In construction, cutting machinery is used for preparing structural materials, from steel beams to wooden frames.

Automotive and Aerospace

- These industries rely on cutting machinery for fabricating parts with tight tolerances and complex geometries.

Metal Fabrication

- Cutting machine is at the heart of metal fabrication, used for shaping metal sheets and components.

Woodworking and Furniture Making

- From basic cuts to intricate designs, cutting machinery is crucial in woodworking and furniture production.

Challenges and Solutions in Cutting machine Use

Maintenance and Upkeep

- Regular maintenance is essential for ensuring the longevity and performance of cutting machine.

Safety Concerns

- The operation of cutting machinery involves safety risks. Proper training and adherence to safety protocols are mandatory to prevent accidents.

Future Trends in Cutting Equipment

Automation and AI Integration

- The future of cutting machinery lies in automation and artificial intelligence, enhancing precision and reducing manual labor.

Sustainable Practices

- Eco-friendly and energy-efficient cutting solutions are becoming increasingly important, aligning with global sustainability goals.

Selecting the Right Cutting Equipment

Understanding Needs

- Choosing the right cutting machinery requires an understanding of the specific needs of the task, including material type, desired precision, and production volume.

Cost-Benefit Analysis

- A careful cost-benefit analysis is vital to select equipment that offers the best value for investment.

Conclusion

Cutting equipment is an indispensable part of modern manufacturing and construction. Its evolution continues to drive industries forward, offering solutions that are precise, efficient, and adaptable. As technology progresses, the capabilities of cutting equipment will only expand, further solidifying its role as a cornerstone in industrial and creative applications.