In the vast landscape of cutting technology, the introduction of the silicone cutting machine marked a significant advancement, offering precision in silicone material handling. Yet, in the specialized field of gemstone cutting, the SHINE Gemstone Cutting Machine emerges as a paramount tool, symbolizing the epitome of precision and craftsmanship.

The SHINE Gemstone Cutting Machine, designed for the intricate demands of gemstone artistry, seamlessly complements the utility of silicone cutting machines, broadening the horizons for creative possibilities in both jewelry and detailed silicone projects. This machine stands as a testament to SHINE’s commitment to quality, transforming raw gemstones into dazzling treasures with unparalleled accuracy.

As we explore the features of the SHINE Gemstone Cutting Machine, we see how it elevates the craft of gemstone cutting, ensuring each piece reflects the brilliance achievable with top-tier equipment. Let the SHINE Gemstone Cutting Machine guide you through the world of gemstone artistry, where precision meets beauty in every cut.

The Ultimate Guide to Gemstone Cutting Machines

Gemstone cutting, a craft that combines artistry with precision engineering, transforms raw gemstones into stunning jewels. This guide delves into the world of gemstone cutting machines, covering everything from the types available to tips on choosing the right one for your needs. By understanding these machines, enthusiasts and professionals alike can elevate their gem cutting skills and produce exquisite pieces.

Types of Gemstone Cutting Machines

Faceting Machines

Faceting machines are the artisans’ choice for creating gems with multiple flat surfaces. These machines consist of a head that holds the stone, a motor to rotate the stone, and a control system for precise cuts.

- Manual Faceting Machines: Offer a hands-on approach, allowing the cutter to adjust angles and depth of cut manually.

- Automated Faceting Machines: Use computer controls to ensure uniform facets and highly accurate cuts.

Cabochon Machines

Cabochon machines specialize in shaping and polishing stones into a dome shape, perfect for stones that show their color and pattern best without facets.

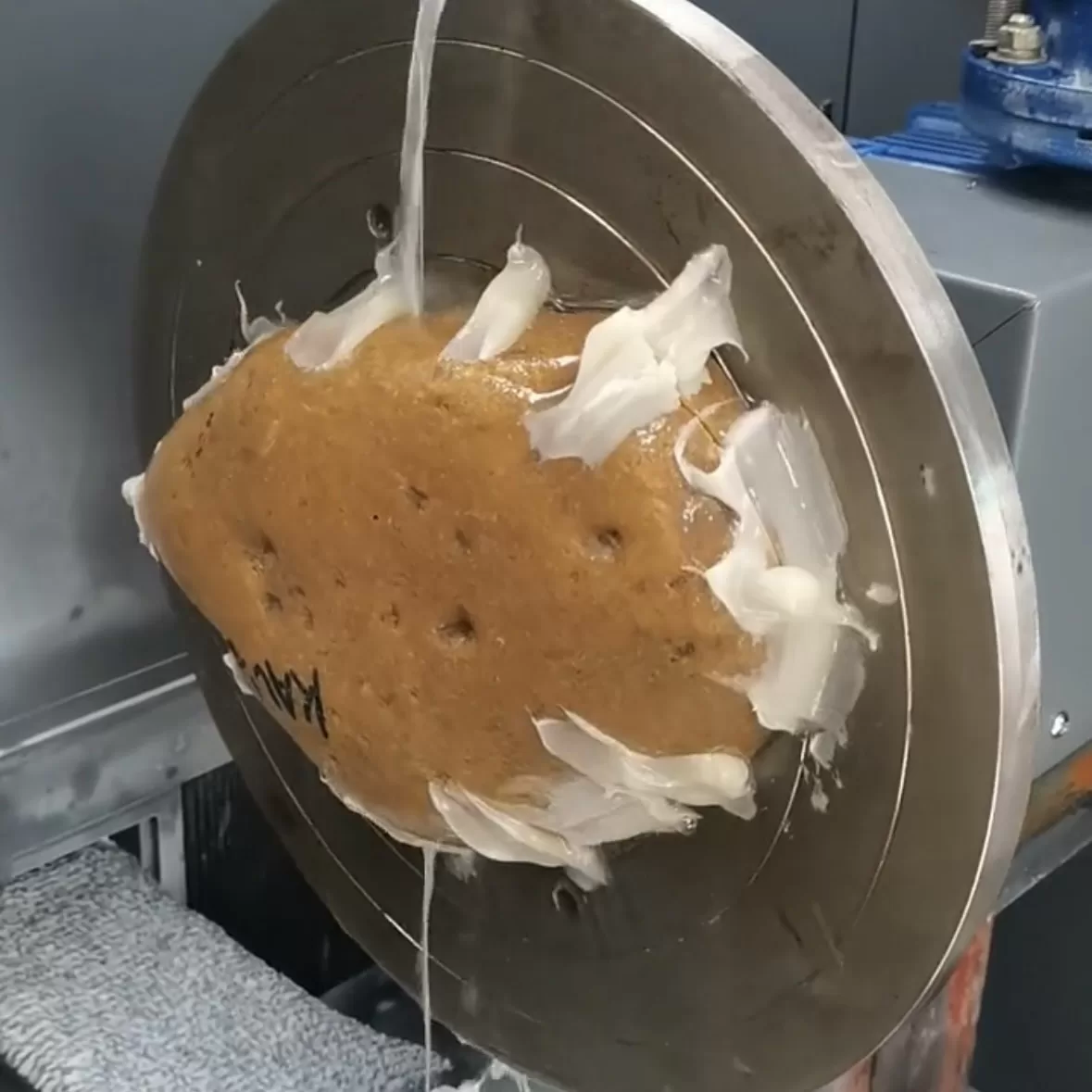

Sawing Machines

These are essential for initial cutting, allowing the user to slice through rough gemstones. The precision of the blade determines the smoothness of the cut.

Drilling Machines

Used for adding holes to gemstones for jewelry making, drilling machines must be precise to avoid cracking the stone.

Factors to Consider When Choosing a Gemstone Cutting Machine

Precision and Accuracy

The essence of gemstone cutting lies in the precision and accuracy of the cuts. A high-quality cutting machine should offer precise control over the cutting angles, depth, and speed. Look for machines that boast of advanced calibration systems and can maintain consistent performance over time. Precision in cutting not only affects the beauty of the final product but also its symmetry, which is crucial for the value of faceted gems.

- Adjustable Settings: Machines with easily adjustable settings allow for more precise cuts.

- Stability: A stable machine reduces vibration, enhancing accuracy during cutting.

Speed and Efficiency

Time is a valuable commodity in gemstone cutting, whether you’re a hobbyist or a professional. The speed at which a machine can cut without sacrificing quality is an important consideration. Efficient machines save time, allowing for higher productivity. However, speed should not compromise the quality of the cut. Balanced machines offer a good speed-to-quality ratio.

- Motor Power: A powerful motor can handle harder gemstones more efficiently.

- Cooling Systems: Machines with effective cooling systems can operate for longer periods without overheating.

Versatility

The ability to cut various types of gemstones and perform different cuts (faceting, cabochon, sawing, etc.) makes a machine more versatile. If your work or hobby involves a wide range of gemstone types and shapes, consider a machine that can accommodate your diverse needs.

- Interchangeable Parts: Look for machines with interchangeable laps, blades, or heads for different cutting tasks.

- Adjustment Range: A broader range of adjustable angles and heights caters to more complex and varied cutting styles.

Size and Portability

The physical size of the machine and its portability may be crucial, depending on your workspace or if you need to move the machine frequently. Compact machines are ideal for small workshops or home environments, but ensure they still have the necessary power and features to meet your cutting needs.

- Footprint: Measure your available space before purchasing to ensure a good fit.

- Weight and Design: Consider how easy it is to move or transport the machine if needed.

Cost

Gemstone cutting machines come in a wide price range, from affordable basic models to expensive professional-grade machines. The cost is often reflective of the machine’s precision, durability, and features. Determine your budget beforehand but be prepared to invest in a higher-quality machine if gemstone cutting is more than just a casual hobby for you.

- Initial Investment vs. Long-Term Value: Higher-priced machines may offer better durability and precision, providing more value over time.

- Included Accessories: Some machines come with additional accessories, which may save money in the long run.

How Gemstone Cutting Machines Work

Gemstone cutting is a multi-step process:

- Initial Cutting: Rough stones are cut into smaller pieces.

- Shaping: Stones are shaped into the desired form, using cabochon or faceting machines.

- Polishing: The final step involves polishing the stone to a brilliant shine.

Maintenance and Safety Tips

- Regular Cleaning: Keep your gemstone cutting machine free from dust and residue to prevent mechanical wear and ensure optimal performance.

- Lubrication: Apply lubricant to moving parts as per the manufacturer’s instructions to maintain smooth operation.

- Blade and Bit Inspection: Check and replace worn blades and bits to ensure precise cuts and reduce the risk of breakage.

- Water Cooling System: For machines equipped with a water cooling system, ensure it is functioning correctly to prevent overheating and damage to both the machine and gemstones.

- Safety Gear: Always wear appropriate safety gear, including safety glasses and gloves, to protect against flying debris and accidental cuts.

- Stable Setup: Ensure the gemstone cutting machine is securely mounted or placed on a stable surface to avoid vibration and potential accidents.

- Electrical Safety: Regularly inspect power cords and plugs for damage, and ensure your workspace is dry to prevent electrical hazards.

- Training and Manuals: Familiarize yourself with the machine’s manual and seek proper training, if necessary, to use the machine safely and effectively.

- Emergency Stop: Know how to quickly turn off your gemstone cutting machine in case of an emergency to prevent injury or damage.

Innovations in Gemstone Cutting Technology

Technological advancements have introduced machines that are faster, more accurate, and user-friendly. Benefits of modern machines include:

- Enhanced Precision: Improved control systems allow for more intricate cuts.

- Increased Efficiency: Faster cutting and polishing save time.

- User-Friendliness: Automated options reduce the learning curve for beginners.

The Role of Gemstone Cutting Machines in Jewelry Making

Gemstone cutting machines play a crucial role in jewelry design, allowing for:

- Unique Gem Shapes: Custom cuts set apart designer pieces.

- Enhanced Gemstone Value: Well-cut gems fetch higher prices due to their enhanced beauty and brilliance.

How to Purchase a Gemstone Cutting Machine: Featuring SHINE

Understanding Your Needs

Before diving into the world of gemstone cutting machines, it’s crucial to assess your needs. Whether you’re a hobbyist looking to explore the art of gemstone cutting or a professional seeking to enhance your workshop’s capabilities, understanding the scope of your projects helps in making an informed decision.

- Project Scope: Consider the types of gemstones you plan to cut and the styles (faceting, cabochon, etc.) you wish to achieve.

- Skill Level: Match the machine’s complexity with your expertise to ensure a smooth learning curve.

Researching Gemstone Cutting Machines

With a clear understanding of your needs, the next step involves researching the options available in the market. The SHINE brand, known for its quality and reliability, offers a range of gemstone cutting machines suitable for various levels of expertise and project sizes.

- Read Reviews: Look for user reviews and professional recommendations to gauge the performance and reliability of SHINE gemstone cutting machines.

- Compare Features: Assess the features of different models, focusing on precision, speed, and versatility to find a machine that meets your requirements.

- Attend Demonstrations: If possible, attend trade shows or demonstrations where SHINE machines are showcased. This provides a hands-on understanding of the machine’s capabilities.

Key Features to Look For

In your quest for the perfect gemstone cutting machine, prioritize the following features to ensure you get the best value for your investment:

- Precision and Accuracy: SHINE machines are celebrated for their precision and accuracy, making them a top choice for professionals and enthusiasts alike.

- Durability: Opt for a machine that promises longevity and robustness, ensuring that your investment stands the test of time.

- Ease of Use: Especially important for beginners, SHINE machines offer user-friendly interfaces and controls, making them accessible to cutters of all skill levels.

- After-Sales Support: Consider the warranty and after-sales support offered by SHINE. Access to maintenance tips, replacement parts, and customer service can significantly enhance your cutting experience.

Budgeting for Your Machine

While the allure of a top-tier gemstone cutting machine is strong, it’s essential to align your choice with your budget. SHINE offers options across various price points, ensuring that quality isn’t compromised for affordability.

- Initial Investment vs. Ongoing Costs: Remember to account for maintenance and accessory costs when budgeting for your SHINE gemstone cutting machine.

- Financing Options: Explore financing options or payment plans if available. This can make higher-end models more accessible without a significant upfront investment.

Making the Purchase

With your research complete and budget in mind, making the purchase becomes the final step. Whether buying directly from SHINE or through an authorized dealer, ensure you receive the genuine product along with all its benefits.

- Verify Authenticity: Purchase your SHINE gemstone cutting machine from reputable sources to ensure authenticity and warranty coverage.

- Check for Special Offers: Look out for promotions or bundle deals that can provide additional value.

DIY Gemstone Cutting: Tips and Tricks

- Start with Simple Projects: Begin your journey with easier cuts to gain confidence using your gemstone cutting machine.

- Choose the Right Machine: Invest in a gemstone cutting machine that matches your skill level and project needs, ensuring it has the capability for both cutting and polishing.

- Practice on Affordable Stones: Before working on valuable gemstones, practice cutting techniques on less expensive stones to minimize costly mistakes.

- Understand Your Machine: Spend time learning about your gemstone cutting machine’s features and maintenance needs for optimal performance.

- Maintain Proper Safety: Always wear safety equipment, like goggles and gloves, to protect yourself from flying debris when operating the machine.

- Keep Blades Sharp: Regularly check and replace the cutting blades or wheels to ensure clean and precise cuts.

- Use Water Cooling: If your machine has a water cooling system, use it to prevent overheating of the gemstone and reduce dust.

- Study Gemstone Properties: Familiarize yourself with the physical properties of different gemstones to adapt your cutting technique accordingly.

- Join Online Communities: Engage with online forums or social media groups focused on gemstone cutting to gain insights, tips, and support from fellow enthusiasts.

Professional Advice for Gemstone Cutters

Experienced cutters suggest:

- Mastering basic cuts before attempting more complex designs.

- Continuously learning about new techniques and machine capabilities.

The Future of Gemstone Cutting

The gemstone cutting industry continues to evolve, with a focus on sustainability and efficiency. Future trends may include:

- Eco-friendly Practices: Reducing waste and using environmentally friendly materials.

- Advanced Technologies: Further automation and precision in cutting machines.

Conclusion

In summary, selecting the ideal gemstone cutting machine is a crucial decision that can significantly impact the quality and efficiency of your gemstone crafting endeavors. By considering your needs, doing thorough research, and prioritizing key features such as precision, durability, and ease of use, you’re well on your way to making an informed choice. The SHINE brand stands out as a beacon of quality and reliability in the gemstone cutting machine market, offering a range of machines that cater to both novices and seasoned professionals.

With SHINE gemstone cutting machines, you’re not just purchasing a tool; you’re investing in an opportunity to elevate your gemstone cutting artistry to new heights. These machines are designed to help you achieve impeccable precision and stunning results, whether you’re working on small personal projects or large professional endeavors.

As you consider your next steps, remember that choosing a SHINE gemstone cutting machine is an investment in your craft’s future. The brand’s commitment to quality, combined with its range of products, ensures that there’s a machine perfectly suited to your requirements. We encourage you to explore the options available, consult with SHINE experts, and select a machine that will not only meet but exceed your expectations.

Call to Action: Don’t let the perfect gemstone remain hidden in the rough. Embrace the precision and quality of SHINE gemstone cutting machines and unlock the true potential of your gemstones today. Visit the SHINE website or contact a SHINE authorized dealer to discover how you can transform your gemstone cutting experience and bring your artistic visions to life.

FAQs

- What is the best gemstone cutting machine for beginners?

- A simple faceting machine or a basic cabochon machine is ideal for beginners due to their ease of use and learning curve.

- How do I maintain my gemstone cutting machine?

- Regular cleaning, oiling, and replacing worn parts are key to maintaining your machine’s performance.

- Can I cut any type of gemstone with a standard cutting machine?

- While standard machines can handle many types of gemstones, extremely hard or soft stones may require specialized equipment.

- How much does a good gemstone cutting machine cost?

- Costs vary widely based on features and precision, ranging from a few hundred to several thousand dollars.

- Are there any safety precautions I should take while using a gemstone cutting machine?

- Always wear safety glasses, follow the manufacturer’s guidelines, and ensure proper machine guarding for safety.