-Graphite Cutting Machine/Diamond Wire Saw

Table of Contents

Graphite Cutting Wire Saw Machine Brief Description

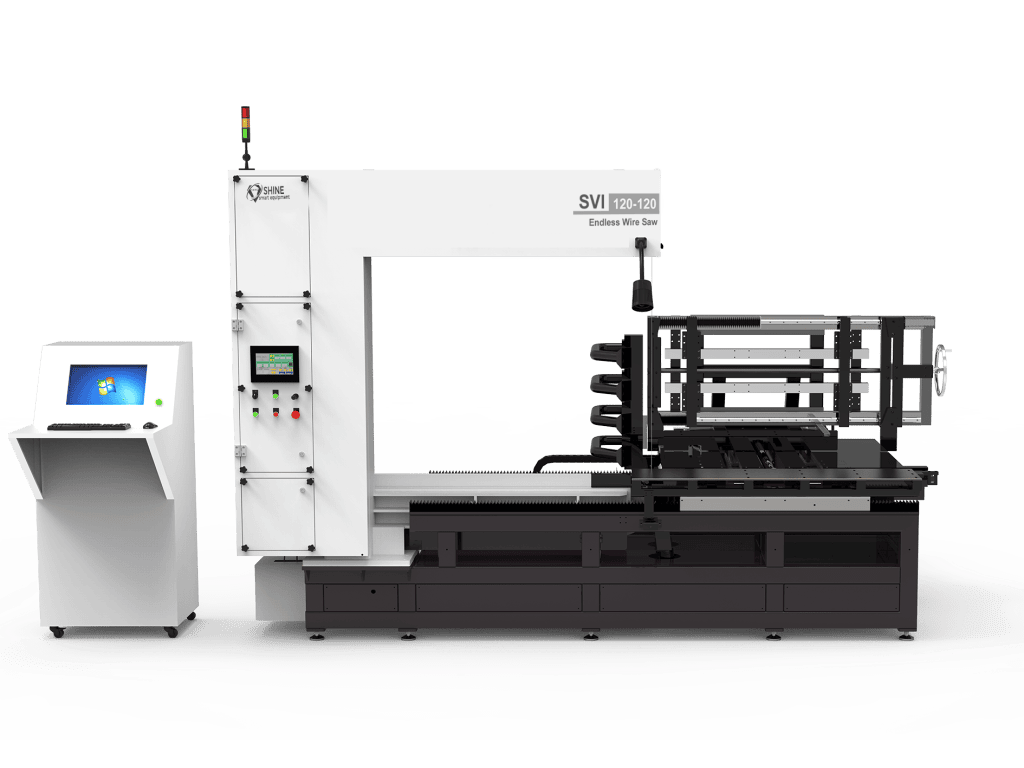

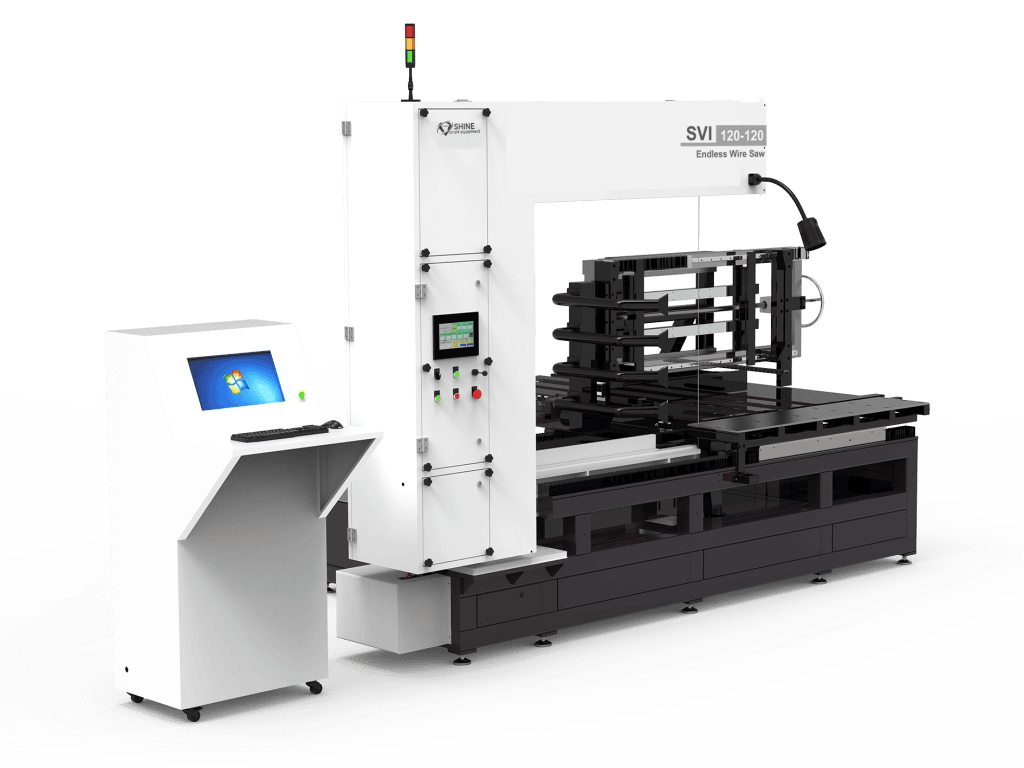

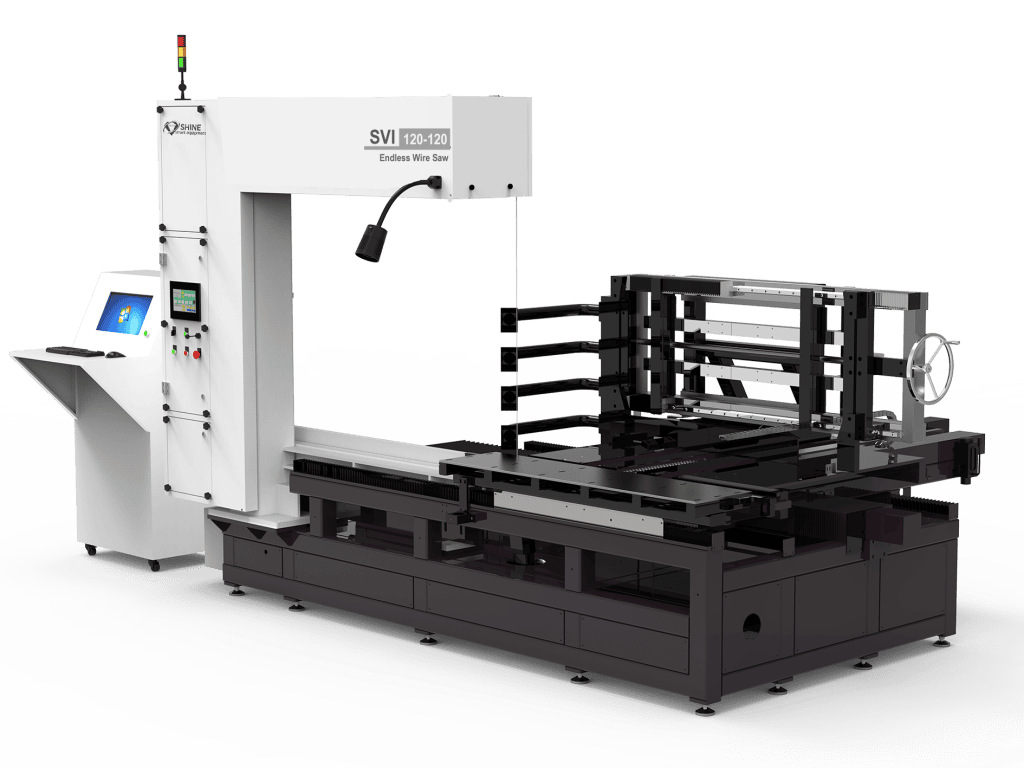

Introducing the SVS120-120 Endless Diamond Wire Cutting Machine, a breakthrough in cutting technology. With its endless diamond wire tool, it can effortlessly cut non-conductive materials without the need for electrical power. Operating at speeds up to 80 m/s, its unidirectional motion ensures precision and exceptional cut surface quality. Tailored for graphite cutting, we have a range of models to suit various material sizes. Simply provide your material dimensions, and we’ll recommend the perfect model for your needs.

Efficiency and precision are just a click away. Contact us today to embark on a cutting journey like never before.

Graphite Cutting Wiresaw Machine Video Introduction

Unique features, performance, and advantages of graphite cutting machine

1,Exceptional Sharpness:

The use of diamond as the cutting tool, combined with the high wire speed of up to 80 m/s, ensures that the SVS120-120 is exceptionally sharp. Diamond is one of the hardest materials known, providing superior cutting capabilities.

2,Superior Surface Quality:

The continuous motion of the endless diamond wire and the precision of its unidirectional movement result in a consistently smooth cutting action. This meticulous control leads to superior cut surface quality.

3,Minimal Kerf Width:

Our Machine designing concept and the thinness of the diamond wire contribute to a narrow kerf width of approximately 0.7 mm. This minimizes material wastage and maximizes efficiency.

4,Low Dust Emissions:

Unlike traditional cutting methods that generate more dust, our graphite cutting machine produces minimal dust.

5,High Precision:

The unidirectional motion of the endless diamond wire ensures precise cuts with minimal deviation. This high level of precision is a result of the machine’s advanced technology and engineering.

6,Versatile Cutting Length:

the absence of restrictions on the length of the endless diamond wire allows the machine to adapt to a wide range of product sizes, offering versatility and flexibility in cutting operations.

Comparison Between Diamond Band Saw and a Single Diamond Wire Saw

here’s a comparison sheet highlighting the differences between a Diamond Band Saw and a Diamond Wire Saw when cutting graphite:

| Aspect | Diamond Band Saw | Endless Diamond Wire Saw |

| Cutting Mechanism | Utilizes a continuous loop of diamond-coated band as the cutting tool. | Employs a continuous loop of diamond-coated wire as the cutting tool. |

| Cutting Speed | Generally slower cutting speed due to the movement of the band. | Faster cutting speed due to the continuous linear motion of the wire. |

| Kerf Width | Typically has a wider kerf width, leading to more material wastage. | Minimizes kerf width, resulting in minimal material wastage. |

| Cut Surface Quality | May require additional polishing steps to achieve a smooth finish. | Simultaneously cuts and polishes, ensuring a smooth and shiny surface. |

| Versatility | Suitable for basic cuts and straight lines. | Highly versatile, suitable for complex shapes and intricate designs. |

| Precision | Moderate precision; may not achieve intricate designs accurately. | Offers high precision, ideal for intricate graphite components. |

| Material Efficiency | Can be less material-efficient due to wider cuts. | Maximizes material efficiency with narrow cuts. |

| Dust Generation | Generates more dust, potentially requiring dust extraction systems. | Produces minimal dust, contributing to a cleaner working environment. |

| Application | Mainly used for simpler cutting tasks | Ideal for various cutting needs, especially intricate graphite parts. |

| Ideal Use Case | Basic straight cuts in graphite. | Precision cuts, intricate designs, and complex graphite components. |

Get In Touch

Graphite Cutting Machine Product Detail

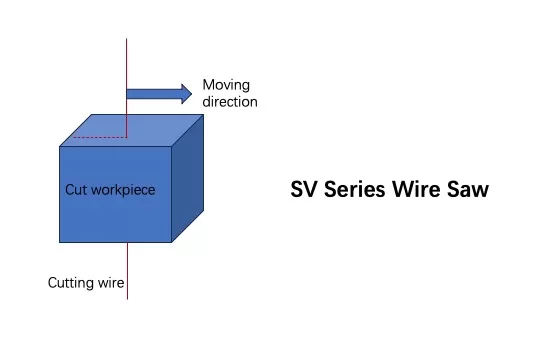

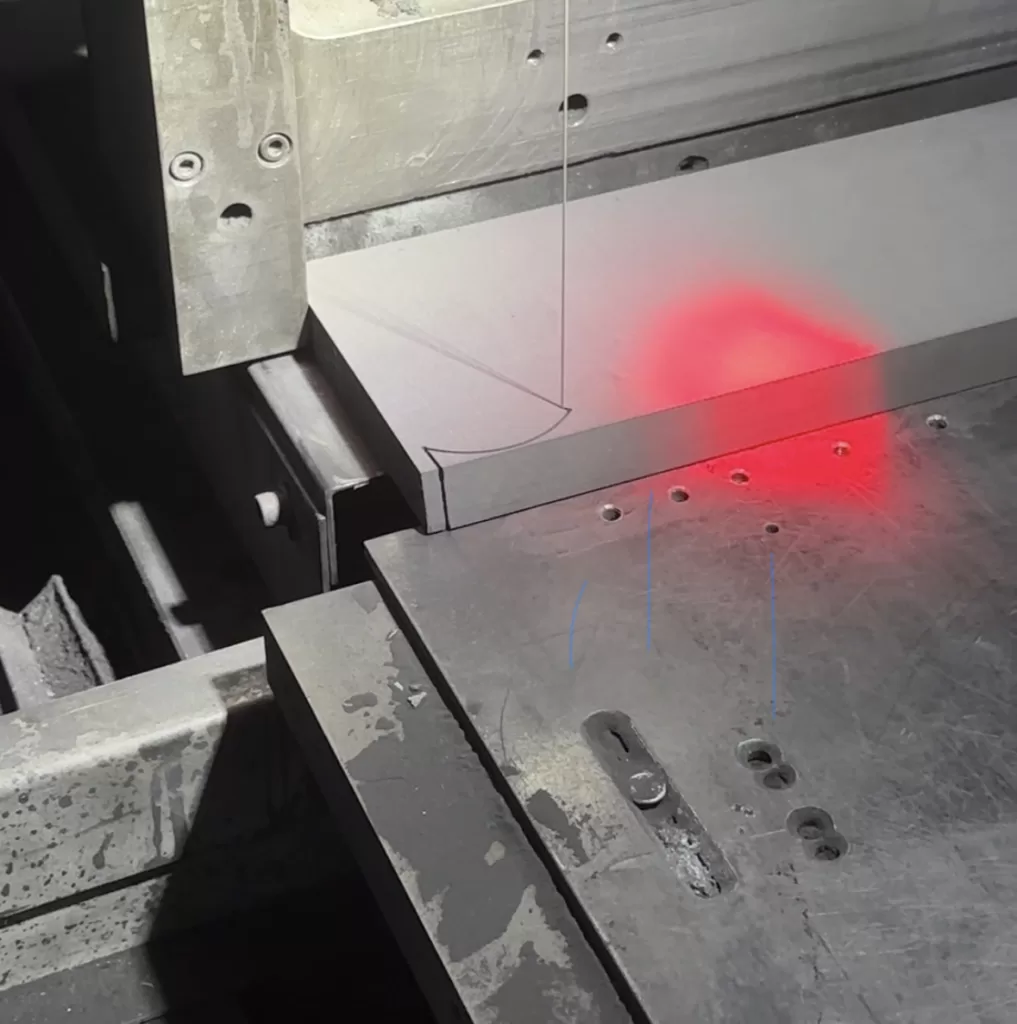

The working principle of this Graphite Wire Cutting Machine

The cutting line of the equipment is perpendicular to the ground, and the workpiece is securely fastened to the equipment’s loading platform with a fixture. The cutting line moves in one direction at a speed of approximately 80 m/s while simultaneously performing the cutting through horizontal movement facilitated by the guide wheel system

1,Vertical cutting:

As the cutting wire moves, whole wheel system move from left to right, allowing for Vertical cutting of the workpiece.

Drawing of vertical cutting

How vertical cutting machine works

2,Control and Precision:

This wire cutting equipment comes with two sets of systems. The standard model is equipped with a linear cutting system, which is used for slicing the workpiece. Additionally, there is a contour cutting system, which can be used for cutting both internal and external contours of the workpiece. This contour cutting system is an optional feature and comes with an additional charge.

The equipment offers exceptionally high cutting precision, with accuracy ranging from 0.05mm to 0.1mm, depending on the workpiece size.

Typical specifications for this Graphite Cutting Machine:

Machine Spec

1, Machine Dimension: L3200 mm*W2600 mm*H2400 mm

2 Power:7.5 kw 380V

3 Motor speed:2840 RMP

4 Total Weight:3500 KG

5 loading capacity: 1200 KG

6 Max linear speed:84 m/s

Material Dimension

Material dimension : smaller than 1.2 *1.2*1.2 M

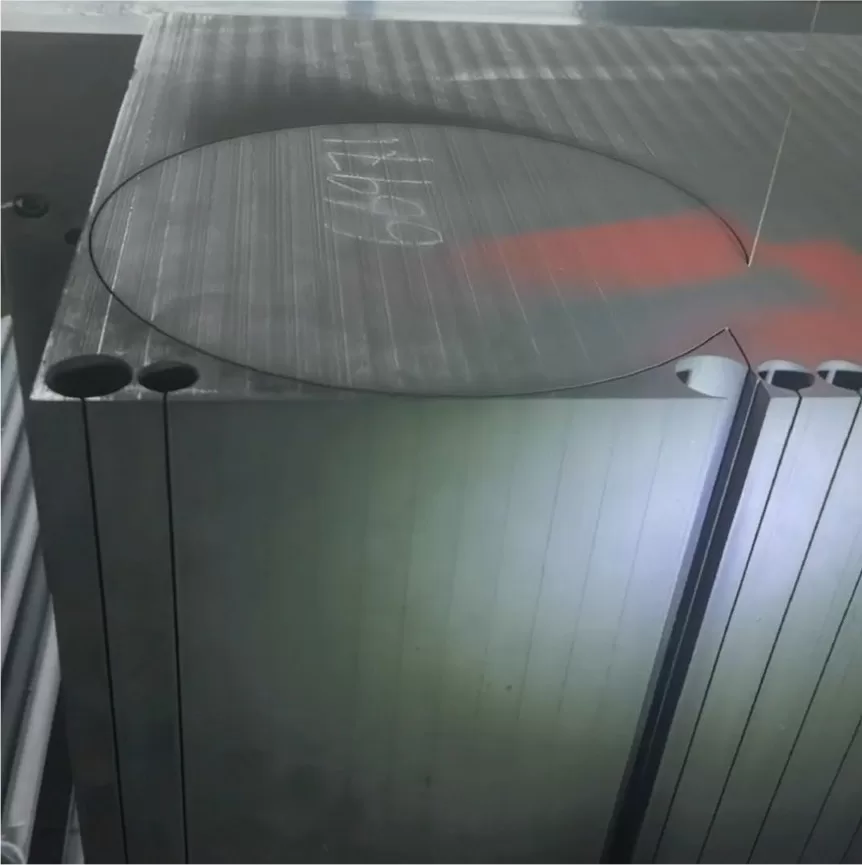

Machine Pre-shipment Inspection

Client bring their product to our factory to make cut test, once the end product meet their request, the machine will be sent to their factory.

Other Graphite Wire Cutting Models

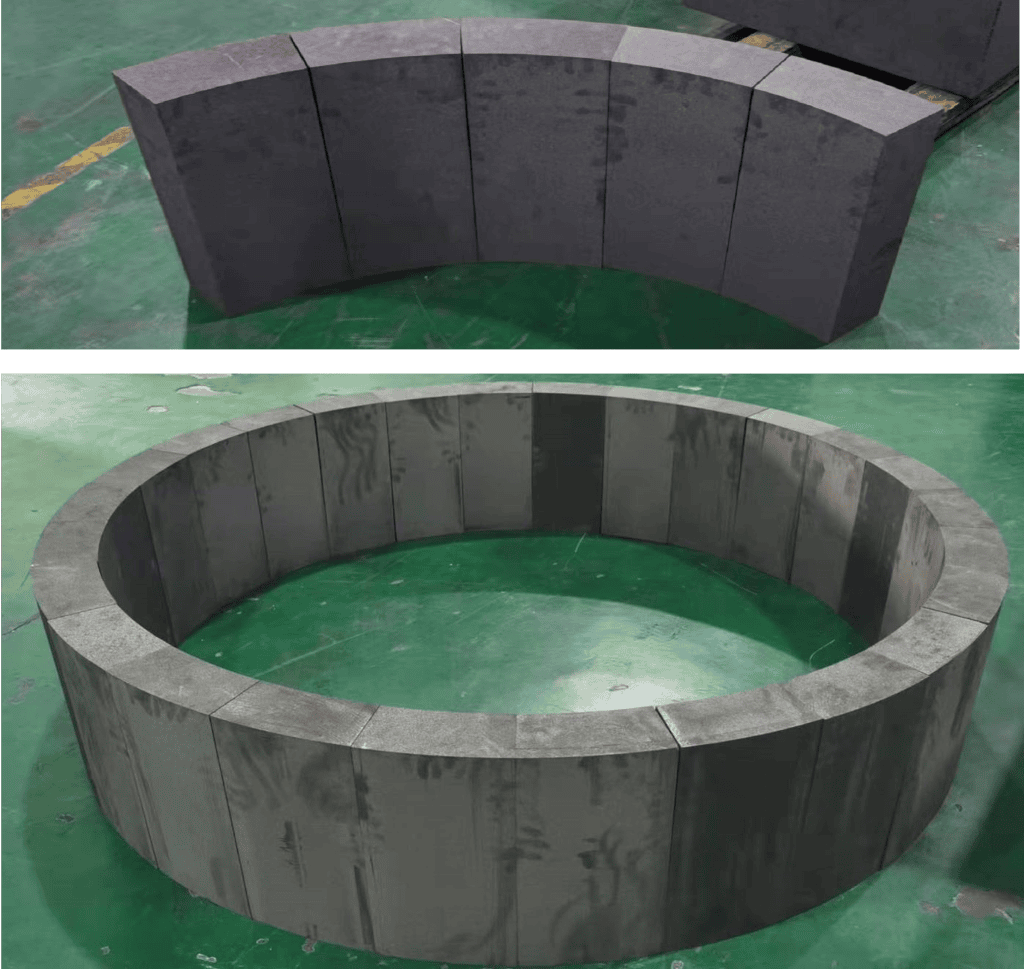

We have a wide range of equipment models available. Please contact us for recommendations on the equipment that suits your needs. Below is an overview of the SV Remote Series equipment. Due to our strong customization capabilities, we also offer some non-standard equipment, such as cutting circles and cutting squares.

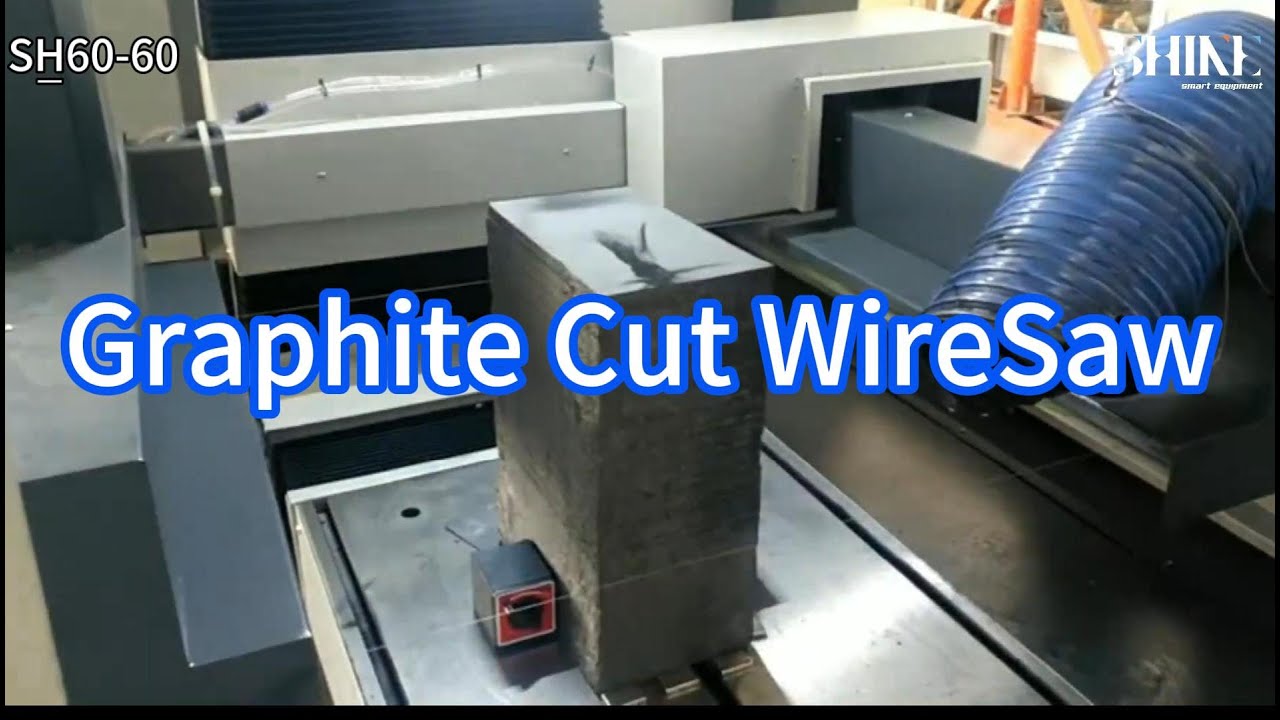

SH60-60 graphite cutting machine:

SV80-80 smart graphite cutting machine

Successful application in different industries which need to cut Graphite:

1,Battery Manufacturing Industry:

Graphite is used as an electrode material in lithium-ion batteries and fuel cells. The battery manufacturing industry requires cutting graphite to prepare electrode sheets.

2,Semiconductor Industry:

In semiconductor manufacturing, graphite is used for making masks for silicon wafers and other process steps. Graphite cutting is employed to customize the shape and size of these masks.

3,Mechanical Manufacturing Industry:

The mechanical manufacturing industry may require graphite components and needs to cut and machine graphite to create parts or molds.

4,Aerospace Industry:

The aerospace industry may use graphite to manufacture aerospace components such as rudders, steam nozzles, and heat-resistant materials. These materials may require cutting and machining.

5,Chemical Industry:

Some chemical processes require graphite as a corrosion-resistant material, necessitating cutting to fit specific reactors or equipment.

6,Glass Industry:

Graphite molds are often made in the glass manufacturing industry and require cutting and machining.

7,Solar Cell Manufacturing Industry:

Silicon wafers used in solar cells typically need to be cut to the appropriate size using graphite cutting processes.

8,Electronic Equipment Manufacturing Industry:

In electronic devices, materials like thermal conductive substances or encapsulation materials may require graphite and, consequently, cutting.

9,Chemical Equipment Manufacturing Industry:

Graphite finds applications in manufacturing chemical equipment such as heat exchangers, reactors, and pipelines, necessitating cutting processes.

Pictures of successful case our Graphite Cutting Machine

Support and Services

Maintenance and Servicing:

We provide comprehensive maintenance and servicing services to ensure the long-term reliable operation of the silicon rod cutting equipment. Our dedicated maintenance team possesses extensive experience and technical knowledge to promptly respond to and resolve equipment issues. We made check list to conduct regular preventive maintenance, inspecting and adjusting critical components to ensure optimal performance and accuracy. Whether it’s routine maintenance or emergency repairs, we are committed to delivering fast and efficient servicing to minimize equipment downtime.

And we have local service available in Canada.

Training:

We offer comprehensive training programs designed to empower customers with in-depth knowledge and proficiency in operating and maintaining the silicon ingot cutting machine. Our training courses cover basic equipment operation, safe usage practices, maintenance procedures, and troubleshooting. Customized training content and flexible training methods, including on-site training, remote training, and provision of training materials, are provided based on customer needs and backgrounds. Through our training programs, customers can enhance their operational skills, improve equipment efficiency, and ensure long-term reliable performance.

Consulting:

We provide professional consulting services to meet customer needs regarding silicon ingot cutting machine and related areas. Our team of experts offers tailored advice and solutions based on specific requirements. Whether it’s equipment selection, process optimization, production line layout, or quality control, we collaborate with customers, providing professional guidance and technical support. We strive to establish long-term partnerships with customers, working together to address various technical and engineering challenges, meet their needs, and achieve mutual success.

Perfectly Solve Your Cutting Problems

Vertical wirecutting machine can be adapted to all cutting scene with an satisfying performance

We accept sample cutting service, leave your information and enjoy our free cutting test service →

-1536x1024.jpg)

-1-1536x886.jpg)

.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1-1536x861.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1536x1024.jpg)