Table of Contents

A Graphite Processing Machine is a specialized type of equipment used for precision cutting, shaping, and machining of graphite materials. Graphite, known for its unique properties like high conductivity, thermal resistance, and strength at high temperatures, requires specific machinery for processing. Here’s an overview of graphite cutting machines:

Characteristics of Graphite Processing Machines:

- Precision Cutting: Graphite cutting machines are designed to achieve high precision and accuracy. This is crucial given the typical use of graphite in detailed and sensitive applications.

- Customization for Graphite: Since graphite is a brittle material, these machines often have specialized components and settings to handle its unique properties without causing excessive breakage or dust.

- Dust Management: Graphite machining generates a significant amount of fine dust. Graphite Processing Machines are usually equipped with effective dust extraction and management systems to maintain a clean working environment and protect the machinery.

- CNC Technology: Many modern Graphite Processing Machines are CNC (Computer Numerical Control) machines. They offer automated, precise, and repeatable cutting processes which are essential for complex designs and large production runs.

Applications of Graphite Processing Machines:

- Electrode Manufacturing: Graphite is widely used in electrode manufacturing for electrical discharge machining (EDM). Graphite Processing Machines are used to shape these electrodes with high precision.

- Nuclear and Aerospace Applications: Graphite is used in nuclear reactors and aerospace engineering due to its thermal resistance and strength. Precision cutting of graphite components is crucial in these high-stakes applications.

- Industrial Applications: In various industrial applications, graphite is used for making crucibles, molds, and other components that need to withstand high temperatures. Graphite Processing Machines are essential for shaping these items.

Types of Graphite Processing Machines:

- Milling Machines: CNC milling machines are commonly used for graphite cutting, providing flexibility in creating complex shapes and fine details.

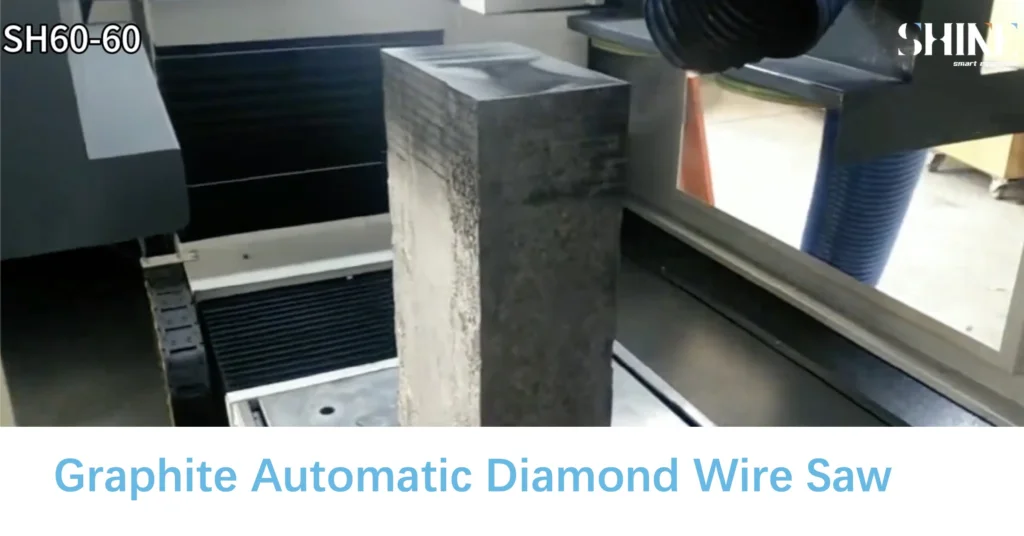

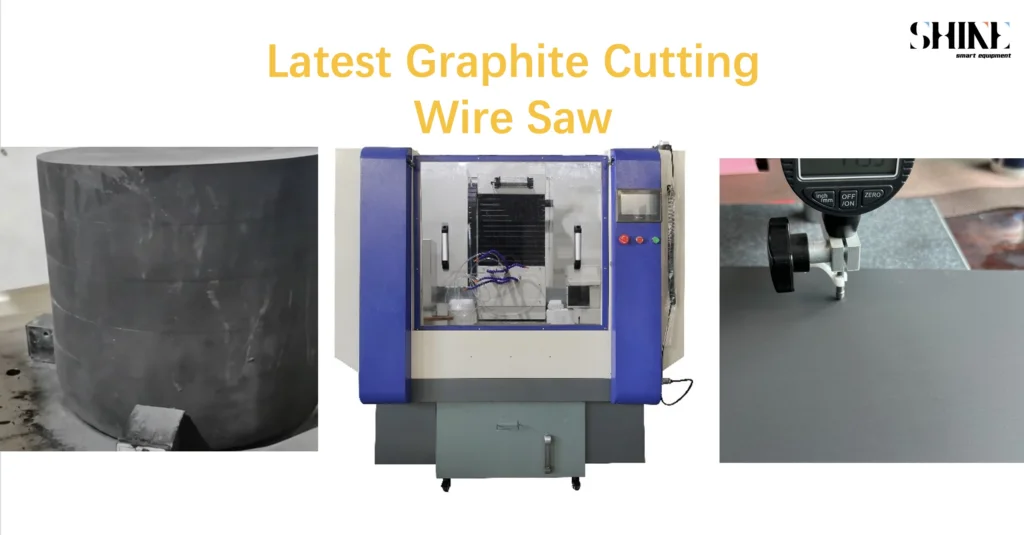

- Band Saws and Wire Saws: For simpler cuts or larger pieces of graphite, band saws and wire saws with specific blades designed for graphite can be used.

Exploring Graphite Processing Machines: Advantages, and Disadvantages

1. CNC Milling Machines

Advantages:

- Precision and Versatility: CNC milling machines offer unparalleled precision in cutting graphite, suitable for complex shapes and intricate designs.

- Automated Control: CNC technology enables automated operations, ensuring consistency and repeatability in production.

Disadvantages:

- Cost: High initial investment for advanced CNC machinery.

- Technical Skill Required: Operating and programming CNC machines require skilled personnel.

2. Band Saws

Advantages:

- Suitability for Larger Pieces: Band saws are effective for cutting larger blocks of graphite into smaller sizes.

- Simple Operation: These machines are generally straightforward to operate and maintain.

Disadvantages:

- Limited Precision: Not suitable for intricate or detailed cutting.

- Dust Management: Additional dust extraction systems may be necessary due to graphite’s dusty nature.

3. Wire Saws

Advantages:

- Intricate Cuts: Wire saws can make more intricate cuts than band saws, offering better precision for detailed work.

- Flexibility in Cutting: The wire saw is more flexible, allowing for diverse cutting patterns.

Disadvantages:

- Wire Breakage: The thin wire can be prone to breakage, requiring regular monitoring and replacement.

- Slower Cutting Speed: Generally, wire saws operate at slower speeds compared to other cutting methods.

4. Laser Cutting Machines

Advantages:

- Extreme Precision: Laser cutters provide extremely precise cuts, ideal for detailed and intricate designs.

- Non-Contact Process: Reduces the risk of material damage or deformation.

Disadvantages:

- High Energy Consumption: Laser cutters typically require significant energy, increasing operational costs.

- Limited Thickness: Not ideal for cutting very thick graphite materials.

Conclusion

Each type of Graphite Processing Machine offers unique advantages tailored to specific needs in the graphite processing industry. CNC milling machines are ideal for complex and precise cuts, while band saws and wire saws offer solutions for larger blocks and intricate patterns, respectively. Laser cutting machines, with their high precision, are suited for detailed work. The choice of machine depends on the specific requirements of the task, including the precision needed, the size of the graphite material, and the desired production speed. Understanding these nuances is essential for leveraging the right technology in graphite machining and fabrication.