Diamond Wire Cut Machine With

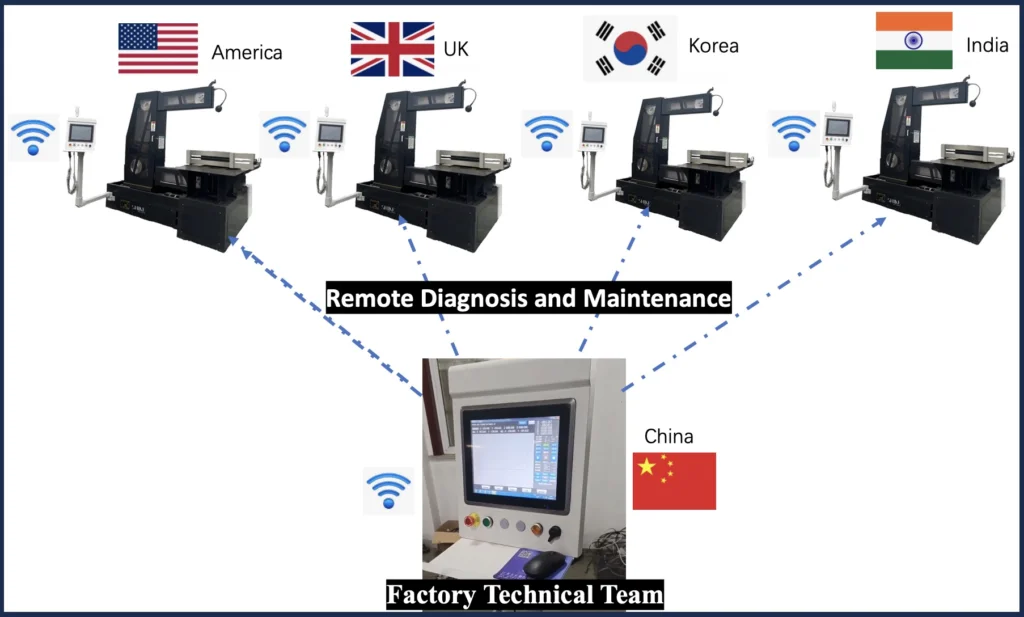

Remote Technical Guidance

Connected to wireless network, enabling remote diagnosis and maintenance of equipment.

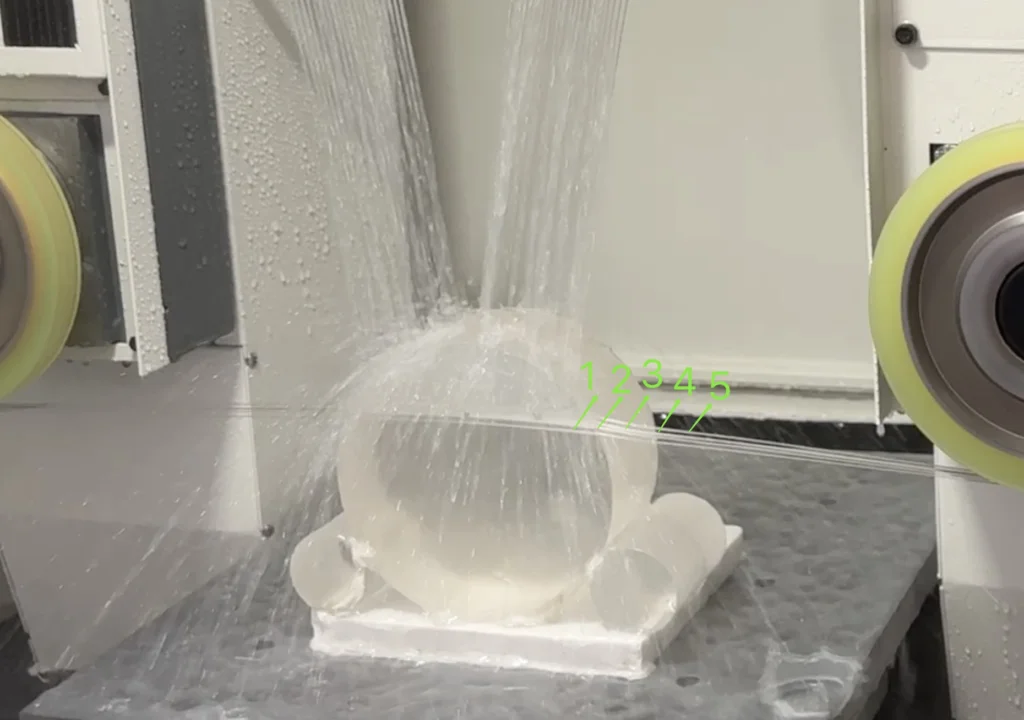

5 Wire Cutting Machine

Cutting with 5 wires simultaneously results in the production of 5 finished pieces at once, directly increasing efficiency by 5 times.

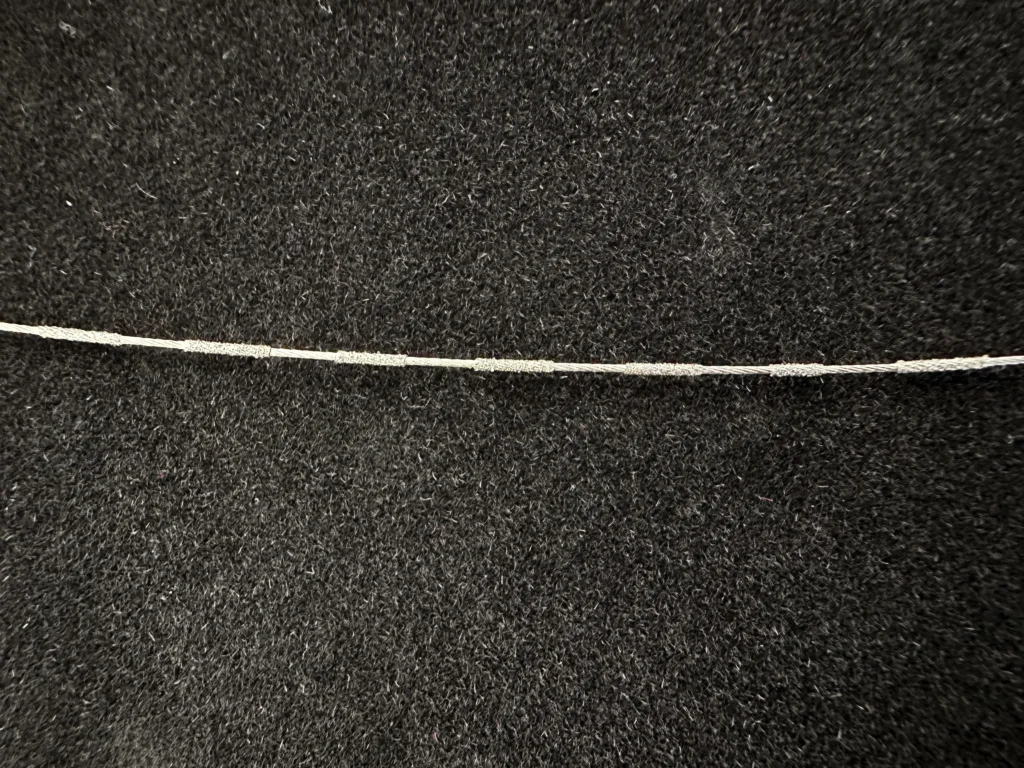

Thread Coated Diamond Wire Loop

Improving the surface coating of traditional loop diamond wires to a threaded pattern enhances chip removal and heat dissipation capabilities. This advancement can increase cutting lifespan by 2 to 3 times.

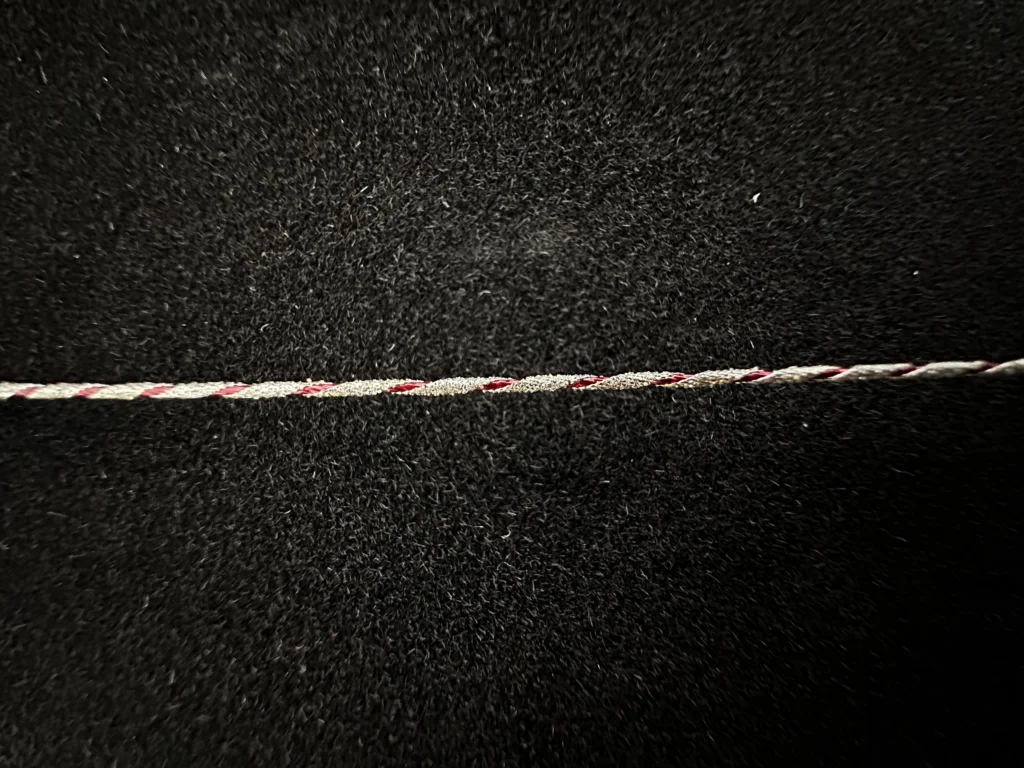

Segment Coated Diamond Wire Loop

The intermittent coating makes the diamond wire more flexible, allowing for a thicker diameter of up to 3.5mm. This versatility enables its application in various cutting scenarios.