Introduction

In today’s advanced manufacturing landscape, material cutting machines play a crucial role. From intricate designs in aerospace to basic cuts in construction, the diversity and precision these machines offer are unparalleled. This article explores various types of material cutting machines, illustrating how they cater to different industry needs.

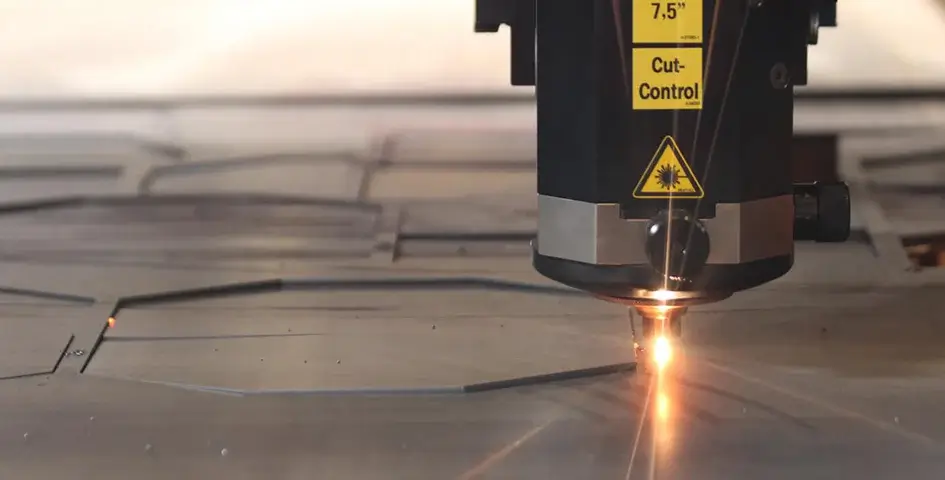

1,Laser Cutting Machines: Precision and Versatility

Laser cutting machines, known for their precision, use high-powered lasers to cut materials like metal, plastic, and glass. Their versatility makes them invaluable in industries requiring detailed and precise cuts. From automotive parts to intricate jewelry, laser cutting machines offer a combination of speed, accuracy, and flexibility.

2,Water Jet Cutting Machines: Power and Adaptability

Water jet cutting machines employ high-pressure water, sometimes with added abrasives, to cut a variety of materials. Ideal for materials sensitive to high temperatures, these machines are used in metal fabrication, stone cutting, and glass processing. Their adaptability allows for cutting complex shapes without altering the material’s inherent properties.

3,Plasma Cutting Machines: Efficiency in Metalwork

Plasma cutting machines are essential in metalworking, especially for conductive materials. Utilizing a plasma torch, they are particularly effective for thick metal sheets, used in shipbuilding, automotive, and construction industries. Their ability to cut quickly and efficiently makes them a staple in heavy fabrication work.

4,CNC Milling Machines: Computer-Controlled Precision

CNC milling machines, controlled by computerized technology, can cut, carve, and shape various materials. Their precision is crucial in creating complex parts for machinery, aerospace components, and intricate woodworking. The versatility of CNC milling machines in handling diverse materials, from wood to titanium, is a testament to their adaptability.

5,Band Saws and Circular Saws: Essential Woodworking Tools

Band saws and circular saws are common in woodworking and metalworking. Band saws, known for cutting curves and irregular shapes, and circular saws, used for straight and rapid cuts, are indispensable in construction and furniture making. Their ease of use and ability to handle various materials make them fundamental in any workshop.

6,Chainsaws: Beyond Timber Cutting

While primarily used in forestry for cutting trees, chainsaws also find applications in artistic fields like ice and wood sculpting. Their portability and power make them ideal for outdoor and artistic uses, demonstrating the versatility of material cutting machines.

7,Die Cut Machines: Crafting and Fabrication

Die cut machines are perfect for softer materials like paper, fabric, and thin plastic. Used extensively in crafting, fashion, and graphic design, they offer precision in replicating shapes and designs. These machines highlight the importance of material cutting machines in creative industries.

8,Oxy-Fuel Cutting Machines: Handling Thick Metals

Oxy-fuel material cutting machines use a combination of fuel gases and oxygen to cut through thick metals. Essential in industrial metal fabrication, they are particularly effective for dismantling and recycling heavy machinery. Their robustness makes them ideal for environments where electric cutting tools might not be suitable.

9,Wire EDM Machines: The Choice for Conductive Materials

Wire EDM (Electrical Discharge Machining) machines use electrical discharges to cut conductive materials. They are ideal for creating intricate components in tool and die manufacturing, especially for hard metals that are difficult to machine with traditional methods.

10, Fiber Laser Cutting Machines: Cutting-Edge Technology

Fiber laser material cutting machines, similar to traditional laser cutters, use a fiber laser source. They are particularly effective for cutting reflective metals and are widely used in electronics and automotive industries. Their high efficiency and speed make them a preferred choice for precision metal cutting.

11, Guillotine Shears: Precision in Sheet Metal Cutting

Guillotine shears are used in metal fabrication for cutting sheet metal. Their ability to make straight, clean cuts with minimal waste makes them a valuable tool in the fabrication of metal parts and components.

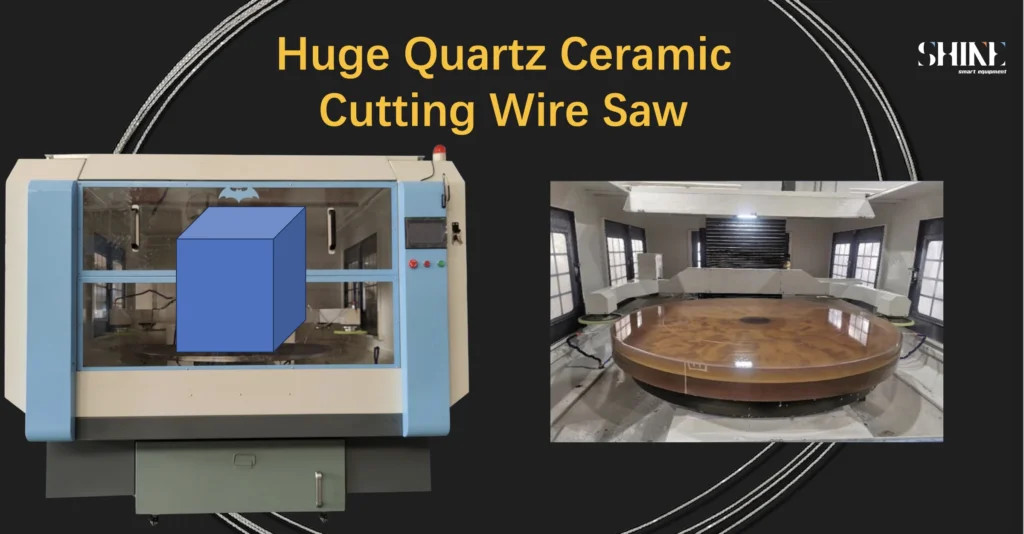

12, Diamond Wire Cutting Machines: Cutting Hard Materials

Diamond wire cutting machines use a wire impregnated with diamond particles to cut hard materials like stone, glass, and concrete. Their precision is crucial in quarrying and construction, where accuracy and minimal material waste are important.

13, Endless Diamond Wire Cutting Machines: A Step Ahead

Endless diamond wire cutting machines represent an advancement in diamond wire cutting technology. Their continuous loop of diamond wire allows for uninterrupted cutting, making them more efficient than traditional diamond wire cutters.

14, Router Machines: Versatility in Woodworking

Router machines, often used in woodworking, are ideal for cutting and shaping wood. They can also be used on materials like plastics and foams, demonstrating their versatility.

15, 3D Water Jet Cutting Machines: Three-Dimensional Precision

3D water jet material cutting machines are advanced versions of traditional water jet cutters, capable of making intricate cuts in various materials in three dimensions. They represent the cutting edge of material cutting technology, offering unparalleled precision and flexibility.

Conclusion of different material cutting machine

Material cutting machines, encompassing a wide range of technologies and applications, are indispensable in modern manufacturing and creative industries. From laser cutting machines to advanced 3D water jet cutters, these tools offer precision, efficiency, and versatility. As technology continues to evolve, the role of material cutting machines in shaping the future of manufacturing and design remains pivotal.