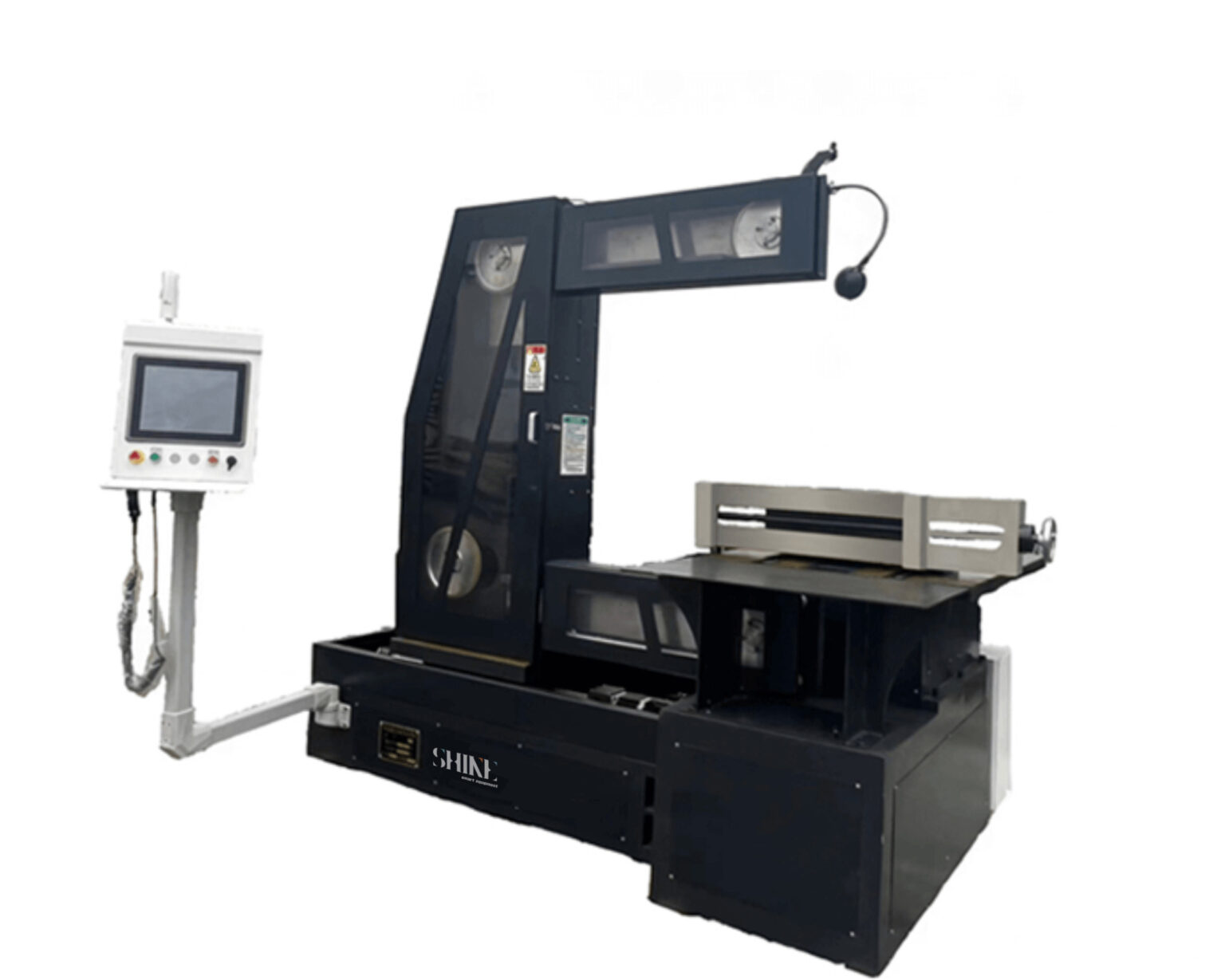

-(Wire Cutting Machine)with Highly Intelligent Remote Control System

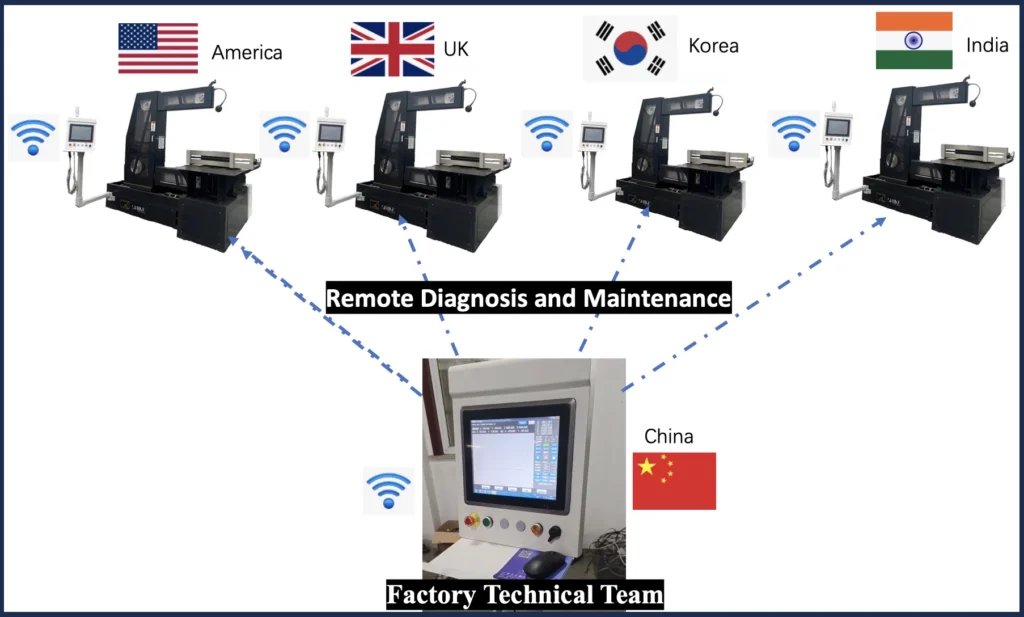

The highlight of this diamond wire cut machine is its highly intelligent operating system, which can connect to wireless networks and enable remote diagnostics and upgrades. The manufacturer can promptly diagnose and maintain equipment issues, significantly reducing the probability of equipment failure. This is a crucial advantage for overseas customers, perfectly addressing concerns regarding after-sales issues.

Click on the text above to quickly jump to the corresponding section.

Swinging Wire Cutting Machine Client On-site Video

Unique advantages of This Diamond Wire Cut Machine

1,After-sales Worry-free:

The CNC system hardware of this equipment is composed of a fully self-developed embedded specialized system, which is powerful and features wireless remote system update capability. The manufacturer can conduct remote diagnosis and maintenance anytime, anywhere, regardless of where the equipment is sold.

2,Super Simple Operation

The CNC software system is a highly intelligent software system. The dedicated main chip operates at a frequency of up to 800MHz and has been specially optimized for big data processing. Therefore, direct cutting can be performed simply and intuitively through straightforward cutting size settings.

3,comprehensive system protection

The system features cutting adaptive control, automatic tracking of machining trajectories, real-time display of cutting processes, and convenient operation functions such as machining preview. At the same time, it also has an automatic memory protection function for power failure, ensuring comprehensive protection against various faults such as power outages and system crashes.

4,Exceptional Sharpness:

The use of diamond as the cutting tool, combined with the high wire speed of up to 80 m/s, ensures that the SVS120-120 is exceptionally sharp. Diamond is one of the hardest materials known, providing superior cutting capabilities.

5,Superior Surface Quality:

The continuous motion of the endless diamond wire and the precision of its unidirectional movement result in a consistently smooth cutting action. This meticulous control leads to superior cut surface quality.

6,Minimal Kerf Width:

Our Machine designing concept and the thinness of the diamond wire contribute to a narrow kerf width of approximately 0.7 mm. This minimizes material wastage and maximizes efficiency.

7,Low Dust Emissions:

Unlike traditional cutting methods that generate a lot dust, The diamod wire cut machine SVI80-80 is equipped with a dust extraction device, which prevents dust from dispersing into the air.

8,High Precision:

The unidirectional motion of the endless diamond wire ensures precise cuts with minimal deviation. This high level of precision is a result of the machine’s advanced technology and engineering.

9,Versatile Cutting Length:

the absence of restrictions on the length of the endless diamond wire allows the machine to adapt to a wide range of product sizes, offering versatility and flexibility in cutting operations.

Comparison Between Diamond Band Saw and a Single Diamond Wire Saw

here’s a comparison sheet highlighting the differences between a Diamond Band Saw and a Diamond Wire Saw when cutting graphite:

| Aspect | Diamond Band Saw | Endless Diamond Wire Saw |

| Cutting Mechanism | Utilizes a continuous loop of diamond-coated band as the cutting tool. | Employs a continuous loop of diamond-coated wire as the cutting tool. |

| Cutting Speed | Generally slower cutting speed due to the movement of the band. | Faster cutting speed due to the continuous linear motion of the wire. |

| Kerf Width | Typically has a wider kerf width, leading to more material wastage. | Minimizes kerf width, resulting in minimal material wastage. |

| Cut Surface Quality | May require additional polishing steps to achieve a smooth finish. | Simultaneously cuts and polishes, ensuring a smooth and shiny surface. |

| Versatility | Suitable for basic cuts and straight lines. | Highly versatile, suitable for complex shapes and intricate designs. |

| Precision | Moderate precision; may not achieve intricate designs accurately. | Offers high precision, ideal for intricate graphite components. |

| Material Efficiency | Can be less material-efficient due to wider cuts. | Maximizes material efficiency with narrow cuts. |

| Dust Generation | Generates more dust, potentially requiring dust extraction systems. | Produces minimal dust, contributing to a cleaner working environment. |

| Application | Mainly used for simpler cutting tasks | Ideal for various cutting needs, especially intricate graphite parts. |

| Ideal Use Case | Basic straight cuts in graphite. | Precision cuts, intricate designs, and complex graphite components. |

Get In Touch

Diamond Wire Cut Machine SVI 80-80 Details

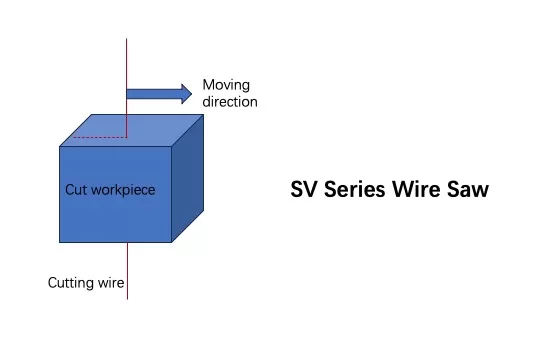

The working principle of this diamond wire saw

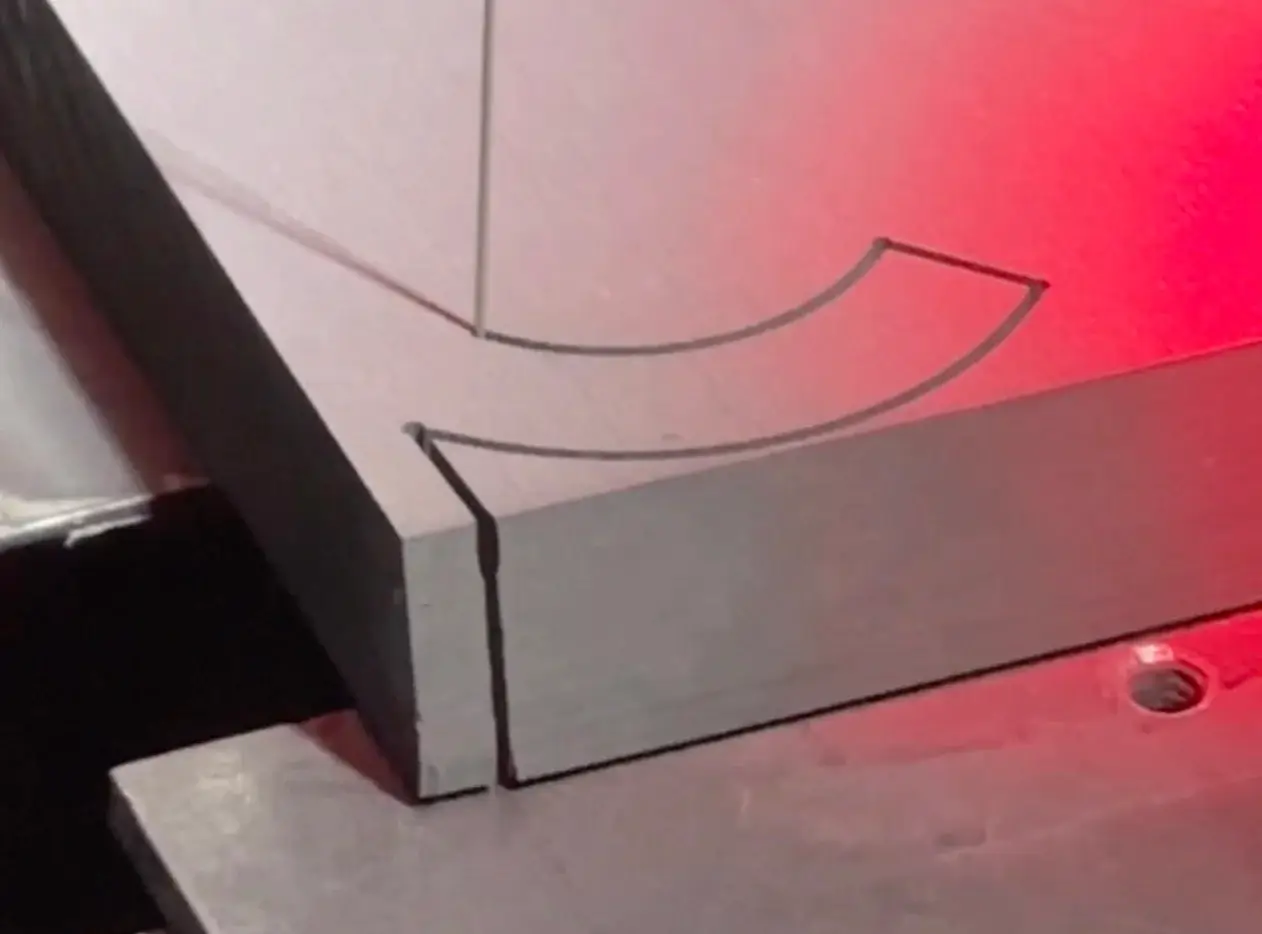

1,Vertical-style Cutting

Drawing of Vertical-style Cutting

2,Control and Precision:

The equipment offers exceptionally high cutting precision, with accuracy ranging from 0.05mm to 0.1 mm, depending on the workpiece size.

Parameter of this SVI80-80 Diamond Wire Cut Machine:

| No. | Name | Specification |

| 1 | Maximum Workpiece Length (mm) | 800 |

| 2 | Maximum Workpiece Width (mm) | 800 |

| 3 | Maximum Workpiece Height (mm) | 700 |

| 4 | Worktable X-Axis Travel (mm) | 800 |

| 5 | Worktable Y-Axis Travel (mm) | 800 |

| 6 | Maximum Diamond Wire Speed (m/s) | 38 |

| 7 | Minimum Feed Increment Y-Axis (mm) | 0.01 |

| 8 | Minimum Feed Increment Z-Axis (mm) | 0.01 |

| 9 | Repeat Positioning Accuracy Y-Axis (mm) | 0.03 |

| 10 | Repeat Positioning Accuracy Z-Axis (mm) | 0.03 |

| 11 | Total Power Consumption (kW) | 4 |

| 12 | Power Supply | 220V 50Hz |

| 13 | Machine Size(mm) | 2500*1700*2200 |

| 14 | Machine Weight(kg) | 2000 |

| 15 | Air Pressure(MPa) | 0.15-0.25 |

Other Models with Same Structure

there are machines of different size and additional function similar to this Machine type.

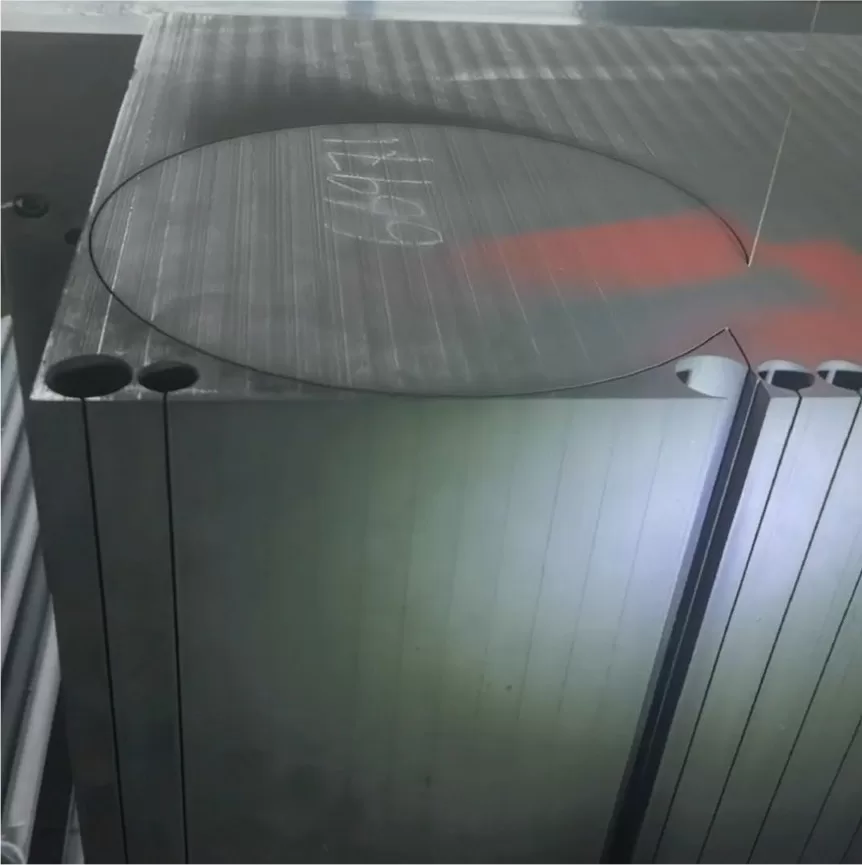

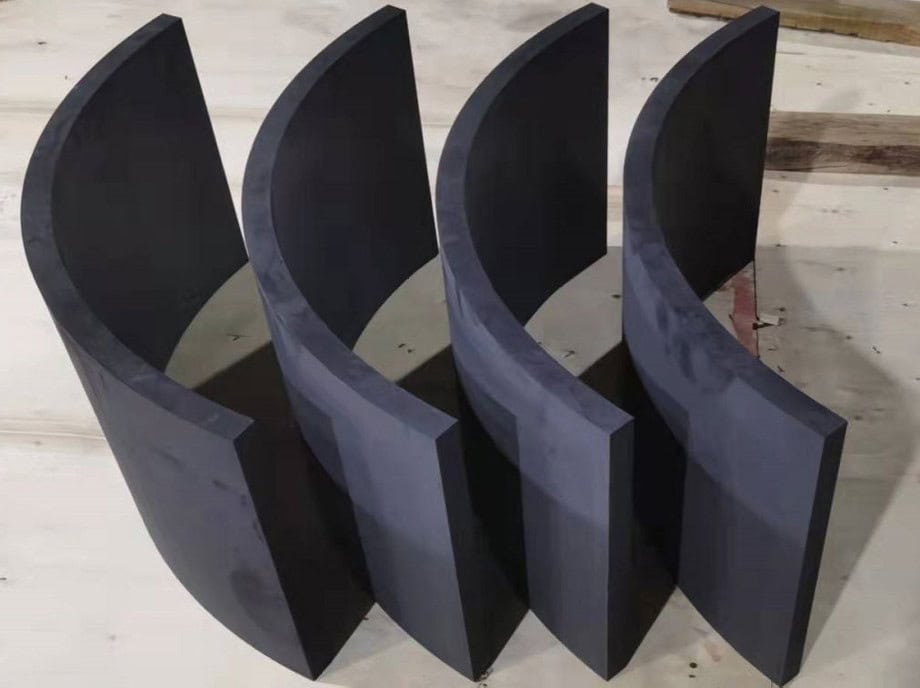

Successful Applications of this SVI80-80

Support and Services

Maintenance and Servicing:

We provide comprehensive maintenance and servicing services to ensure the long-term reliable operation of the Swinging Wire Cutting Machine. Our dedicated maintenance team possesses extensive experience and technical knowledge to promptly respond to and resolve equipment issues. We made check list to conduct regular preventive maintenance, inspecting and adjusting critical components to ensure optimal performance and accuracy. Whether it’s routine maintenance or emergency repairs, we are committed to delivering fast and efficient servicing to minimize equipment downtime.

Training:

We offer comprehensive training programs designed to empower customers with in-depth knowledge and proficiency in operating and maintaining . Our training courses cover basic equipment operation, safe usage practices, maintenance procedures, and troubleshooting. Customized training content and flexible training methods, including on-site training, remote training, and provision of training materials, are provided based on customer needs and backgrounds. Through our training programs, customers can enhance their operational skills, improve equipment efficiency, and ensure long-term reliable performance.

Consulting:

We provide professional consulting services to meet customer needs for this Swinging Wire Cutting Machine. Our team of experts offers tailored advice and solutions based on specific requirements. Whether it’s equipment selection, process optimization, production line layout, or quality control, we collaborate with customers, providing professional guidance and technical support. We strive to establish long-term partnerships with customers, working together to address various technical and engineering challenges, meet their needs, and achieve mutual success.

Perfectly Solve Your Cutting Problems

Vertical wirecutting machine can be adapted to all cutting scene with an satisfying performance

We accept sample cutting service, leave your information and enjoy our free cutting test service →

-1536x1024.jpg)

-1-1536x886.jpg)

.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1-1536x861.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1536x1024.jpg)