私たちが毎日使っているテクノロジーの絶え間ない進歩の原動力は何だろうと考えたことはあるだろうか。ポケットの中のスマートフォンから家庭の電力をまかなうソーラーパネルまで、その秘密はシリコン・クリスタル切断機の心臓部にある。しかし、これらの技術的驚異は、どのようなハードルに直面し、どのようにハイテク産業の成長し続ける要求に応えるために進化し続けているのでしょうか?

精度と革新が出会うシリコン結晶切断の世界へ。以下のような技術で サファイア・ワイヤー切断 シャインのようなブランドが先導するこの革命は、私たちの技術力を再定義することを約束します。未加工のシリコンの結晶がテクノロジーの大国へと変貌を遂げる過程は驚くべきものであり、この魅惑的なプロセスをより深く掘り下げることをお勧めします。

目次

導入

現代社会において、シリコンは無数のデバイスや技術革新のバックボーンとして、テクノロジー分野で極めて重要な役割を果たしています。シリコンの原材料から技術の礎石への道のりの中心には、シリコン結晶切断機の精度と創意工夫があります。本ガイドは、シリコン結晶切断機の重要性、技術、選択基準、用途、そして解決すべき課題について解説し、これらの機械の包括的な概要を提供することを目的としています。

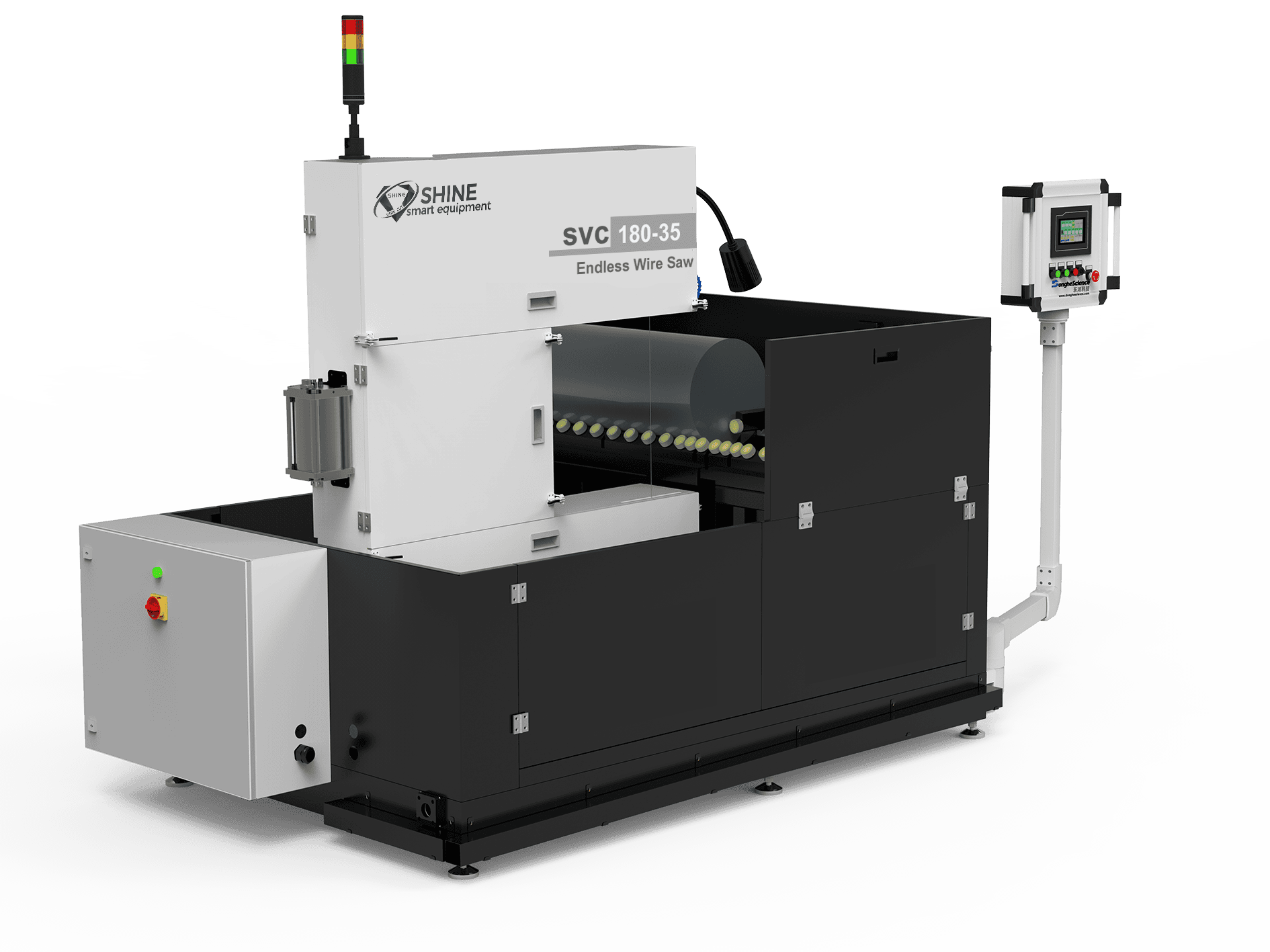

SHINEはこの分野のトップブランドとして、シリコン結晶切断技術の革新と卓越性を実証しています。切断の基本から最新の進歩やトレンドまで、このガイドブックは複雑なシリコン切断の世界をナビゲートし、今日の技術状況における重要な役割を深く理解できるようにします。

パート1:シリコン結晶切断の基本

1.1 シリコン・クリスタル・カッティングとは?

定義と重要性

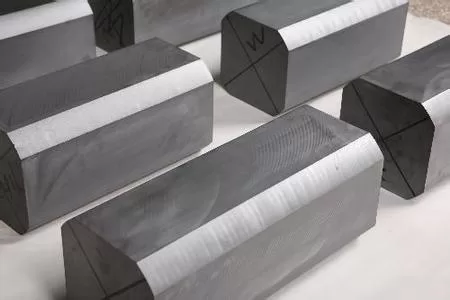

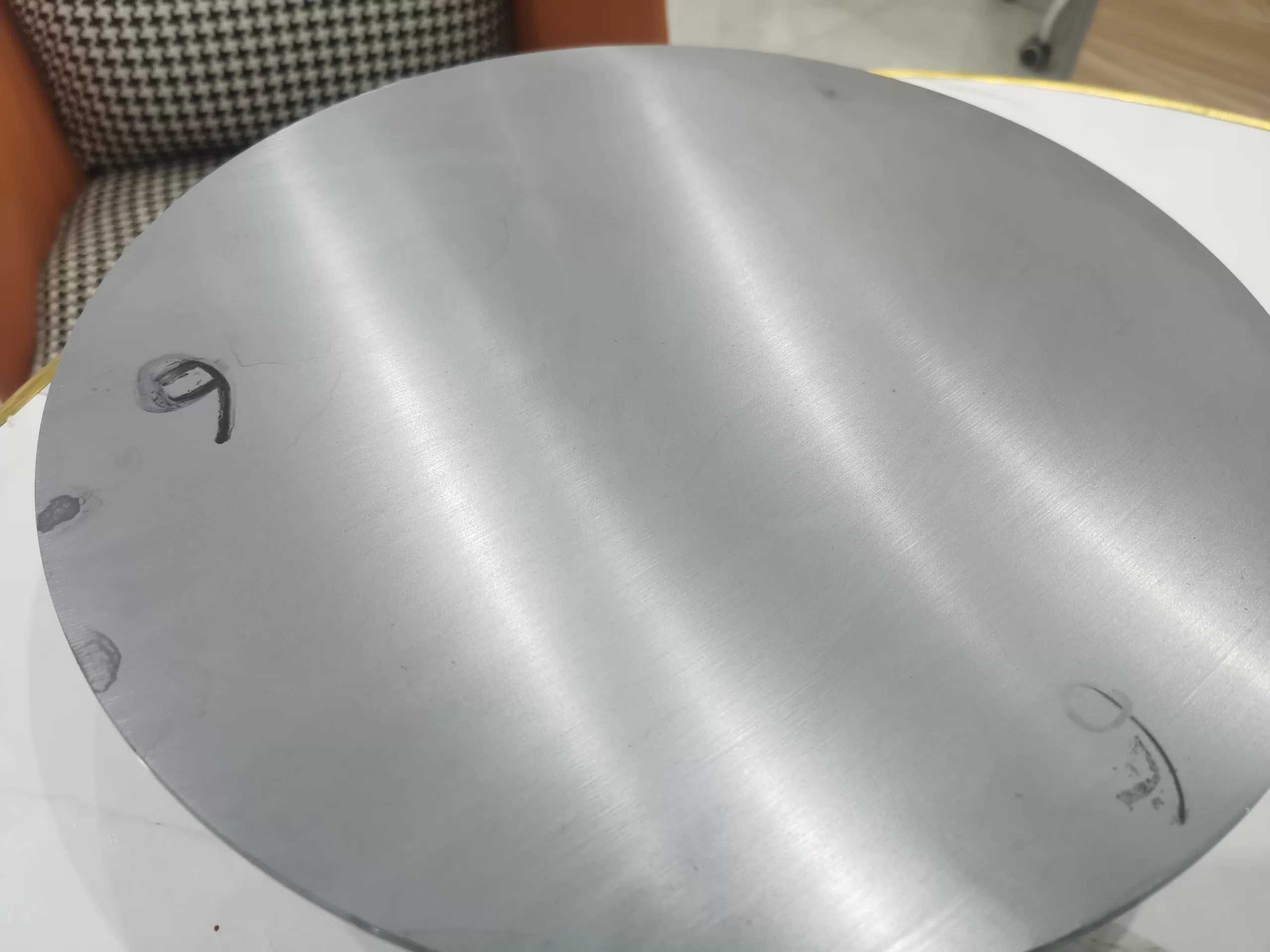

シリコン結晶の切断は、シリコン結晶を薄いウェハーにスライスする工程であり、半導体、太陽電池、その他さまざまな電子機器の製造に使用される。切断の精度は最終製品の効率や性能に直接影響するため、半導体や太陽エネルギーの分野では切断工程が非常に重要となっている。

1.2 シリコン結晶の種類

- 単結晶シリコン:純度と均一性で知られ、半導体用途に高い効率をもたらす。

- 多結晶シリコン:単結晶シリコンよりも安価だが、効率はやや劣る。

1.3 カッティングマシンを理解する

シリコン切断機の仕組み

シリコン切断機は、様々な技術を駆使してシリコン結晶を正確にスライスする。主なコンポーネントには、切断機構(ブレード、レーザー、ワイヤー)、アライメントシステム、精度を保証する制御装置などがあります。

第2部:シリコン結晶切断の技術

2.1 伝統的な裁断技術と現代的な裁断技術

比較と進化

機械的な鋸切断のような伝統的な方法は、レーザー切断やダイヤモンドワイヤー切断のような、より洗練された技術へと進化し、精度の向上と無駄の削減を実現している。

2.2 レーザー切断技術

利点と応用

レーザー切断は、比類のない精度、最小限の材料損失、切断パターンの柔軟性を提供し、複雑な半導体設計に理想的です。

2.3 ダイヤモンドワイヤー切断

プロセスとメリット

ダイヤモンドをちりばめた細いワイヤーを使用するこの方法は、従来のソーイングに比べ、材料の無駄を大幅に減らし、高速で正確な切断を実現する。

2.4 シリコン切断におけるフォトリソグラフィー

役割とイノベーション

それ自体は切断技術ではないが、フォトリソグラフィは切断後のシリコンウェーハのパターニングに重要な役割を果たし、半導体上に複雑な回路を作ることを可能にしている。

パート3:適切なシリコン結晶切断機の選択

3.1 考慮すべき要因

- 精度と正確さ:半導体やソーラーパネル製造の厳しい仕様を満たすために不可欠。

- スピードと効率:生産スループットと全体的な費用対効果を決定します。

- 耐久性とメンテナンス:長期的な運転コストと機械の稼働時間に影響する。

3.2 トップメーカーとブランド

シャインを含む主要メーカーの比較分析から、シリコン結晶切断の領域における革新と品質への取り組みが明らかになりました。

3.3 コスト分析

初期投資と運用コスト

カッティングマシンの初期費用と、継続的なメンテナンスや運用費用とのバランスをとることは、費用対効果の高い生産を行う上で非常に重要である。

SHINEによるシリコン結晶切断機のコスト分析

- 初期投資:シャインのシリコン結晶切断機は、その高度な技術と信頼性で知られています。これにはマシン本体の価格と追加セットアップ費用が含まれます。

- 運営コスト:電気代、切断ワイヤー(ダイヤモンドまたはサファイア)などの消耗品、定期的なメンテナンス材料が毎月の運用費に含まれます。シャインのマシンは省エネ設計で、消耗品の無駄を最小限に抑え、効果的なコスト管理を行っています。

- メンテナンスとアップグレード:定期的なメンテナンスは、シャインのシリコン結晶切断機の寿命と最適な性能を保証します。定期的なアップグレードや部品交換のための予算を組むことは、最新の技術を維持するために不可欠です。

- トレーニングとサポート:オペレーター向けの総合的なトレーニングに投資することで、シャインのカッティングマシンの効率性と生産性を最大限に引き出します。サポート契約により、継続的なサポートとソフトウェアのアップデートが可能です。

- コスト・ベネフィット分析:シャインシリコン結晶切断機の生産性向上、材料浪費の削減、精度の向上に対する総コストの評価は、長期的な経済的利益を示しており、この機械を製造工程を将来にわたって維持するための賢明な投資として位置づけています。

第4部:シリコン結晶切断機の用途

4.1 半導体業界において

チップとマイクロプロセッサの生産

シリコンウエハーの精密切断は、チップやマイクロプロセッサの製造において基礎となるもので、その性能と効率を左右する。

4.2 太陽エネルギー部門

太陽電池の製造

シリコン切断機は、ソーラーパネルの生産において重要な役割を果たし、その効率とコストに影響を与える。

4.3 研究開発

実験的応用

シリコン切断技術の革新は、しばしば研究開発努力から生まれ、半導体技術や太陽エネルギーソリューションのブレークスルーにつながる。

パート5:課題と解決策

5.1 技術的課題

材料の無駄への対応

ダイヤモンドワイヤーカットのような革新的な切断技術は、材料のロスを最小限に抑え、全体的な持続可能性と効率を高めることを目的としている。

切断精度の確保

制御システムと切断技術の進歩は、シリコン結晶切断の精度の限界を押し広げ続けている。

5.2 環境問題

サステナビリティの実践

業界では、廃棄物の削減からエネルギー効率の高い操業に至るまで、環境への影響を軽減する慣行の採用が進んでいる。

5.3 今後の動向

シリコン切断におけるAIと自動化

人工知能と自動化はシリコン切断に革命をもたらし、精度、効率を向上させ、人的ミスを減らす。

パート6:メンテナンスと安全性

6.1 定期メンテナンスのヒント

シャインシリコン結晶切断機の寿命、効率、信頼性を確保するためには、定期的なメンテナンスが極めて重要です。定期的なメンテナンススケジュールを守ることで、ダウンタイムを最小限に抑え、性能を最適化し、装置の寿命を延ばすことができます。ここでは、SHINEマシンを最高の状態に保つための詳しいヒントをご紹介します。

デイリーチェック

- 清潔さ:毎日、マシンの外装と作業エリアの清掃から始めてください。マシンの動作や精度に影響を及ぼす可能性のあるシリコン屑や埃、残留物を取り除いてください。

- 目視検査:切断工具、ワイヤー、レーザーシステムに磨耗や損傷の兆候がないか調べる。問題を早期に発見することで、より重大な問題を未然に防ぐことができる。

ウィークリー・メンテナンス

- 潤滑:スムーズな動作を確保するため、可動部やベアリングは毎週点検し、注油してください。互換性の問題を避けるため、シャインが推奨する潤滑剤を使用してください。

- 冷却システムチェック:オーバーヒートを防止するために、冷却シス テムが正しく機能しているか点検します。フィルタを清掃し、クーラントレベルを点 検して、必要に応じて補充または交換します。

月次検査

- アライメントチェック:すべての切断部品が正しく配置されていることを確認してください。アライメントがずれていると、正確なカットができず、部品の摩耗が大きくなります。

- ワイヤーとブレードの検査:ダイヤモンドまたはサファイアのカッティングワイヤーとブレードに摩耗や損傷がないか点検します。切断の精度と効率を維持するために、必要に応じて交換してください。

- ソフトウェア・アップデート:シャインのソフトウェア・アップデートをチェックし、インストールすることで、最新の改善や機能をご利用いただけます。

四半期ごとのサービシング

- プロフェッショナル検査:四半期ごとにシャインの技術者による専門的な点検を予定してください。定期点検ではわからない問題を特定し、校正を行うことができます。

- ディープクリーニング:日常清掃や週1回の清掃では手が届きにくい場所を中心に、マシン内部を徹底的に清掃する。

年間メンテナンス

- 総合的なオーバーホール:年に一度、消耗部品の交換、マシンの機能テスト、必要な調整など、総合的なメンテナンスチェックを行う。

- パフォーマンス・レビュー:過去1年間のマシンのパフォーマンスを評価し、最適な運転に必要な潜在的な改善や調整を特定する。

文書と記録

- メンテナンス・ログ:シャインシリコン結晶切断機の詳細なメンテナンス記録を保管してください。すべての点検、交換、サービスを記録し、機械のメンテナンス履歴を追跡し、今後の対策を立てる。

- SHINEへのご意見・ご感想:ご使用のマシンのパフォーマンスやメンテナンスに関する問題を、シャインにフィードバックしてください。今後のモデルやメンテナンス手順の改善にお役立てください。

これらの定期メンテナンスのヒントに従うことで、シャインのシリコン結晶切断機が最高の状態で稼働し、比類のない精度と信頼性でお客様の生産ニーズをサポートすることができます。定期的なメンテナンスは装置の寿命を延ばすだけでなく、シャインが誇る高い品質と効率性を維持することにもつながります。

6.2 安全プロトコル

シリコン結晶切断機の運転中の安全確保は最も重要です。以下の手順を遵守することで、事故を防ぎ、安全な作業環境を確保することができます:

- 個人用保護具(PPE):作業者は、飛散する破片や高い騒音レベルなどの潜在的な危険から守るため、安全ゴーグル、手袋、耳あてなどの適切なPPEを着用しなければならない。

- 緊急停止機能:機械の緊急停止機構について、すべての使用者に周知してください。これらの機能が適切に機能しているか定期的にチェックし、必要な場合に直ちに運転を停止できるようにしてください。

- トレーニングと認定:オペレーターには、シリコン結晶切断機を使用するための徹底した訓練と認定を受けさせる。これには、操作マニュアル、安全機能、緊急時の手順を理解することが含まれる。

- 定期メンテナンス・チェック:定期的な保守点検を実施し、部品の緩み、ワイヤーのほつれ、安全ガードの誤作動など、潜在的な危険を特定し、是正する。

- 作業エリアの確保:シリコン結晶切断機の周囲は、清潔で整頓された作業場にしてください。つまずいたり、安全な操作の妨げになるような不要な工具や材料は取り除いてください。

- 換気システム:切削加工中に発生する有害な粉塵やヒュームを除去するため、適切な換気システムを使用すること。これらの換気装置の効率を確保するため、定期的に点検・整備を行うこと。

- 火災安全対策:作業場所に消火器やその他の火災安全設備を設置する。火災を引火または悪化させる恐れのある材料は、切断場所から離れた場所に安全に保管する。

これらの安全プロトコルを実施することにより、シリコン結晶切断機のオペレーターは、リスクを最小限に抑え、より安全な作業環境を作ることができます。新しい安全基準と技術の進歩に適応するために、これらのプロトコルを定期的に見直し、更新することが不可欠である。

結論

シリコン・クリスタル・カッティング・マシンの入り組んだ景観を探検するにつれ、彼らがハイテク業界の隠れたヒーローであることは明らかだ。切り開くたびに、彼らはSFから飛び出してきたかのような進歩への道を切り開く。しかし、材料の無駄を最小限に抑えることから精度を高めることまで、その道のりには困難がつきまとう。しかし、シャインのイノベーションとサファイアとダイヤモンドのワイヤーカッティングにおけるブレークスルーによって、未来は光り輝くのです。

このエキサイティングな旅に参加する準備はできていますか?テクノロジーの最先端を受け入れ、シリコン結晶切断機があなたのプロジェクトに新たな地平を切り開くことを発見してください。ここをクリックして、当社のセレクションをご覧いただき、未来への第一歩を踏み出してください。

特に半導体やソーラーパネル製造におけるシリコン結晶切断機の進歩と応用に関する権威ある洞察については、以下をご覧ください。 IEEE Xploreデジタルライブラリー.このプラットフォームでは、この分野における最新の技術革新やトレンドに関する研究や記事を豊富に提供している。

よくある質問

Q: シリコン・クリスタル・カッティングとは何ですか?

A: シリコン結晶の切断は、半導体やソーラーパネルの製造に不可欠なシリコン結晶を薄いウェハーにスライスする作業です。

Q: なぜシャインをシリコン結晶切断機に選ぶのですか?

A: シャインは技術革新の最前線に立ち、シリコンのスライスにおいて比類のない精度、効率、信頼性を提供する最先端の機械を提供しています。

Q: ダイヤモンド・ワイヤーカッティングはシリコン加工をどのように向上させるのですか?

A: ダイヤモンドワイヤーカッティングは、シリコンをスライスするための正確で効率的な方法を提供し、材料の無駄を省き、半導体用ウェハーの品質を向上させます。

Q: シリコン結晶切断機はソーラーパネル製造に使用できますか?

A: もちろんです。これらの機械は、ソーラーパネルの太陽電池の核となるシリコン・ウェハーを製造する上で極めて重要であり、効率と性能を保証します。

Q: シリコン結晶切断機を選択する際、どのような要素を考慮すべきですか?

A: 主要な検討事項には、精度と速度、メンテナンスの必要性、全体的な耐久性などが含まれ、機械がお客様の生産ニーズを満たすことを保証します。

Q: シリコン・クリスタル・カッティング技術の今後のトレンドは?

A:今後のトレンドとしては、自動化の進展、AIとの統合による精度の向上、環境への影響を最小限に抑えるための持続可能性の実践が挙げられる。