– Compressed Cardboard Cutting Equipment

Brief Description

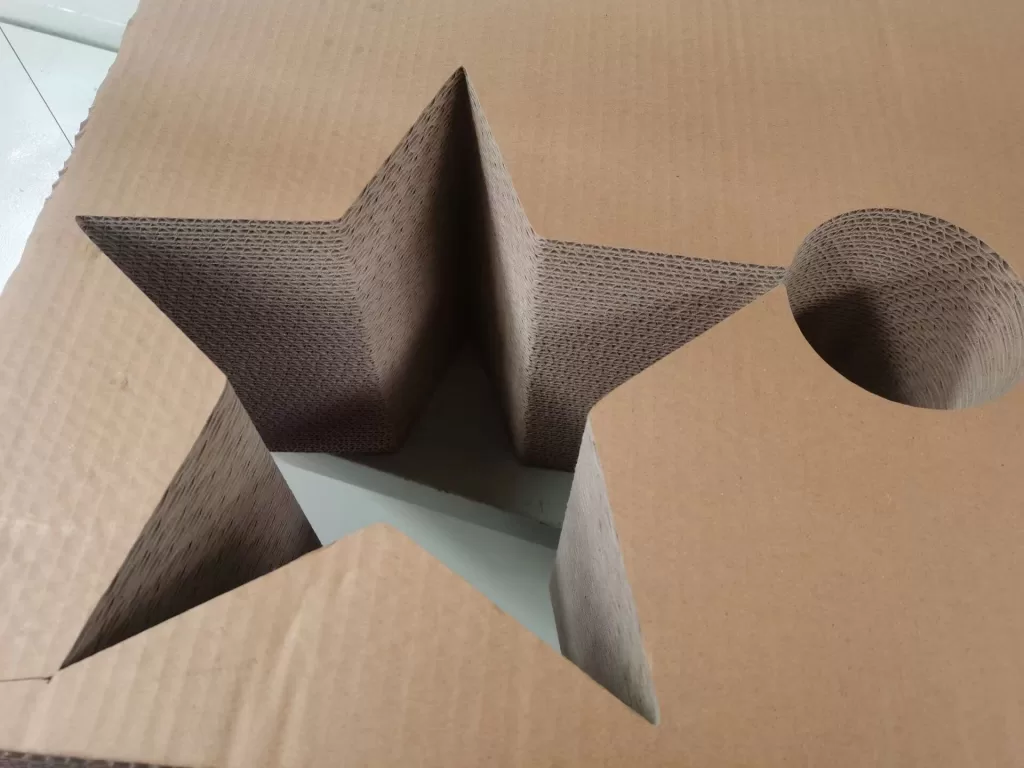

Multi-wire Cutting Machine is a specialized tool used in the pet product industry to create scratchboards for cats. Scratchboards are popular among cat owners as they provide a satisfying outlet for cats to scratch and groom their claws. The cutting equipment is crucial in efficiently producing high-quality scratchboards that meet the needs of both cats and their owners. The endless diamond wire saw, with its unique capabilities, stands out as an ideal cat scratchboard cutting equipment, offering several advantages for this specific application.

Advantages of Our Multi-wire Cutting Machine:

1,Precision Cutting:

Endless diamond wire saws excel in delivering precise cuts with minimal wastage. For cat scratchboards, precision is crucial to ensure the right size and shape, offering cats a satisfying scratching experience. The diamond wire saw’s accuracy helps in producing consistent and uniform scratchboards that meet the exact specifications required.

2,Smooth Edges:

Cats prefer scratchboards with smooth edges, as it enhances their comfort and safety during scratching. The continuous loop of the endless diamond wire saw ensures clean and smooth edges, reducing the risk of splinters or rough surfaces that could potentially harm the cat.

3,Durable and Long-Lasting:

Scratchboards made using the endless diamond wire saw are durable and long-lasting. The wire’s diamond-impregnated nature allows it to withstand repeated scratching without wearing out quickly. This durability ensures that the scratchboards retain their efficacy for an extended period, providing lasting value to pet owners.

4,Reduced Friction:

Endless diamond wire saws operate with reduced friction, generating less heat during the cutting process. This aspect is essential when working with materials like cardboard or fiberboard for scratchboards, as excessive heat could compromise the material’s integrity or cause unpleasant odors.

5,High Efficiency:

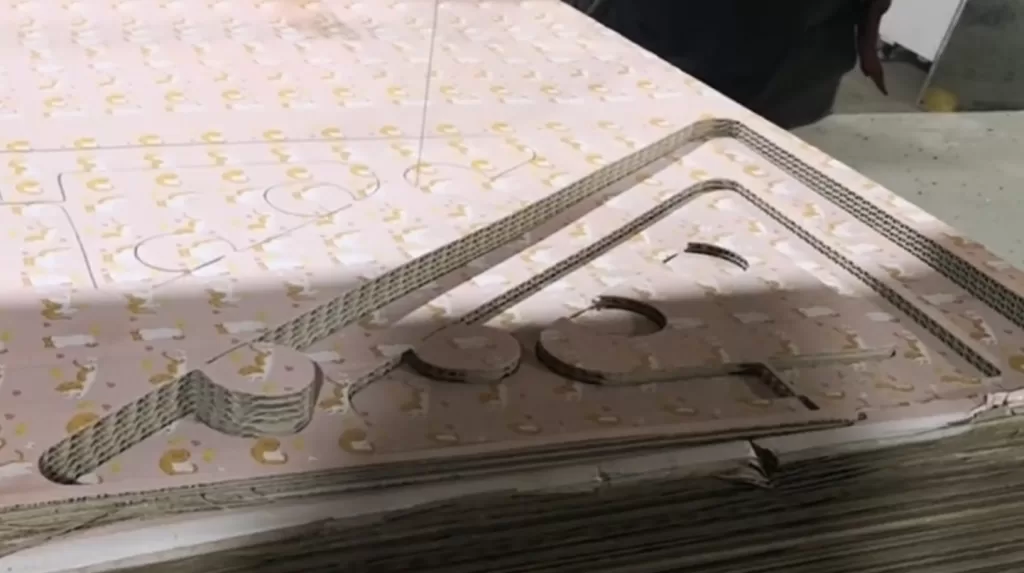

The endless diamond wire saw’s ability to cut multiple scratchboards simultaneously boosts efficiency in production. This is particularly beneficial for manufacturers who need to produce scratchboards in large quantities. The increased efficiency results in shorter production cycles and reduced lead times.

6,Flexibility in Material Selection:

Cat scratchboards can be made from various materials, such as cardboard, corrugated board, or recycled paper. The endless diamond wire saw’s versatility allows it to handle different materials, providing manufacturers with flexibility in creating scratchboards to cater to various customer preferences.

7,Cost-Effectiveness:

The minimal material wastage, high productivity, and durability of scratchboards produced with the endless diamond wire saw contribute to cost-effectiveness in the production process. Manufacturers can optimize material usage and reduce operational costs, ultimately offering competitively priced scratchboards to consumers.

8, Multi cuts

This machine have to working station, you can cut 2 pieces or a lot pieces at one time

Case Studies

Cutting Video of successful case

Pictures of successful case

Successful application examples of Multi-wire Cutting Machine in different industries and projects:

- Grey board

- Corrugated paper

- Honeycomb board

- Particleboard

- Fiberboard

- KT board (Kapa board, foam-centered board)

- Foam and composite materials (fiberglass, carbon fiber)

- Graphite

- Graphene

- Eco-friendly materials

Product Detail

The working principle of this Two-station cutting machine

1,Cutting Line Orientation:

The cutting wire is positioned perpendicular to the ground, while the cut material is horizontally placed on the loading platform.

2,High-Speed Cutting Wire Motion:

The cutting wire moves at high speed along its circular path, maintaining constant tension and maintaining its sharpness during the cutting process.

3,Vertical Cutting:

As the cutting wire moves, the loading platform moves horizontally, allowing for vertical cutting of the silicon rod. This vertical cutting method, known as vertical wire cutting, enables precise and efficient cuts.

4,Simultaneous synchronous cutting at two stations

the precise mechanical design, along with CNC (Computer Numerical Control) programming, ensures that cutting at both stations is completely synchronized, resulting in identical products being produced simultaneousl

4,Control and Precision:

The cutting machine is equipped with a control system that ensures precise movement of the cutting wire and the loading platform. The control system allows for accurate positioning and motion control, resulting in consistent and high-quality cuts.

Typical specifications for this Multi-wire Cutting Machine:

Machine Spec

1 Machine Dimension: L4600*W2000mm*H1800mm

2 Spindle Motor:2.2 kw

3 Total Weight:1700 KG

4 The effective cutting stroke for each station: 900*1200*420mm

6 Cutting speed: 300-2000mm/min

Material Dimension

Material dimension : smaller than 900*1200*420mm 500

Get In Touch

Support and Services of Multi-wire Cutting Machine

Maintenance and Servicing:

We provide comprehensive maintenance and servicing services to ensure the long-term reliable operation of the silicon rod cutting equipment. Our dedicated maintenance team possesses extensive experience and technical knowledge to promptly respond to and resolve equipment issues. We made check list to conduct regular preventive maintenance, inspecting and adjusting critical components to ensure optimal performance and accuracy. Whether it’s routine maintenance or emergency repairs, we are committed to delivering fast and efficient servicing to minimize equipment downtime.

and we have local service available in US and Canada.

Training:

We offer comprehensive training programs designed to empower customers with in-depth knowledge and proficiency in operating and maintaining the silicon ingot cutting machine. Our training courses cover basic equipment operation, safe usage practices, maintenance procedures, and troubleshooting. Customized training content and flexible training methods, including on-site training, remote training, and provision of training materials, are provided based on customer needs and backgrounds. Through our training programs, customers can enhance their operational skills, improve equipment efficiency, and ensure long-term reliable performance.

Consulting:

We provide professional consulting services to meet customer needs regarding silicon ingot cutting machine and related areas. Our team of experts offers tailored advice and solutions based on specific requirements. Whether it’s equipment selection, process optimization, production line layout, or quality control, we collaborate with customers, providing professional guidance and technical support. We strive to establish long-term partnerships with customers, working together to address various technical and engineering challenges, meet their needs, and achieve mutual success.

Contact Us

Perfectly Solve Your Cutting Problems

-1536x1024.jpg)

-1-1536x886.jpg)

.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1-1536x861.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1536x1024.jpg)

-1536x1024.jpg)