Keywords: Porous Metal Cutting,Ring Diamond Wire cutting

Table of Contents

Introduction

Porous metals, characterized by their intricate internal structures with interconnected voids, find application in various industries. These materials are essential components in emerging clean energy technologies like hydrogen fuel cells. However, the complexity of porous metal cutting presents significant challenges in cutting and shaping them to meet specific requirements. Traditional cutting methods struggle to navigate the porous structure, often causing damage and inefficiency. This article explores the application of ring diamond wire cutting in addressing these challenges, particularly in the context of hydrogen fuel cells.

What Are Porous Metals and Where Are They Used?

Porous metals, as the name suggests, are metals with voids or pores within their structure. These voids give the material unique properties, including low density, high surface area, and increased permeability. These characteristics make porous metals suitable for various applications. They are used in:

- Hydrogen Fuel Cells: Porous metal structures are commonly employed in the production of hydrogen fuel cells. These fuel cells require materials that can facilitate efficient chemical reactions while maintaining structural integrity. Porous metals provide the ideal framework for the deposition of catalysts and the flow of reactants.

- Filtration Systems: Porous metal materials are used in filtration systems, where their porous structure allows them to capture and remove contaminants from gases or liquids effectively.

- Heat Exchangers: The high surface area of porous metals makes them suitable for heat exchanger applications, as they enhance heat transfer.

- Biomedical Devices: Some biomedical devices, such as bone implants, utilize porous metal materials that promote the ingrowth of natural tissue.

Despite their diverse applications, cutting and shaping porous metals can be a daunting task.

Challenges in Porous Metal Cutting

Porous metals’ intricate structure poses unique challenges when it comes to cutting and shaping them. Conventional cutting methods, like laser cutting or abrasive methods, may encounter the following difficulties:

- Material Damage: The fine, porous structure can be easily damaged during the cutting process, affecting the material’s properties and structural integrity.

- Inefficient Cutting: The complex internal structure can slow down the cutting process, resulting in inefficiencies, increased costs, and production delays.

- Dust Generation: Porous Metal Cutting can generate a significant amount of dust and waste material, necessitating time-consuming cleanup procedures.

- Lack of Precision: Achieving high-precision cuts is a challenge due to the porous material’s irregularities.

In applications like hydrogen fuel cells, where the electrode structures are critical to performance, these challenges become even more pronounced. This is where ring diamond wire cutting comes into play.

Ring Diamond Wire Cutting: Precision and Efficiency

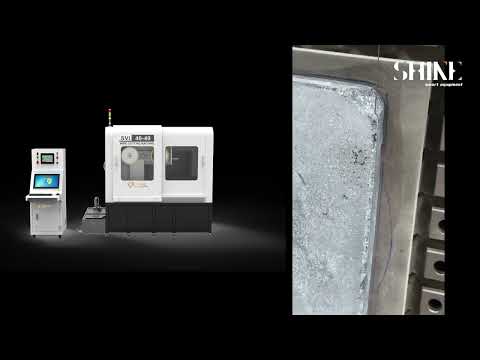

Ring diamond wire cutting presents a viable solution to the challenges associated with Porous Metal Cutting. The method revolves around a closed-loop system, where a thin diamond wire is formed into a closed loop. This wire can rotate at astonishing speeds, reaching over 80 meters per second. This high-speed rotation results in extremely sharp diamond particles capable of swiftly cutting through various materials.

Moreover, the directional motion of the ring diamond wire eliminates the need for frequent tool changes, a common issue with traditional cutting methods. This not only improves efficiency but also ensures that the cut surface remains smooth and free of burrs.

In terms of environmental impact and sustainability, ring diamond wire cutting stands out. It generates minimal waste material and dust, making it a more eco-friendly option compared to traditional methods. The reduction in dust is particularly advantageous in sensitive applications like hydrogen fuel cells, where dust contamination can be detrimental.

Innovations and Future Prospects

Ring diamond wire cutting is continually evolving to meet various cutting needs. Its ability to handle different materials, including porous metal cutting with varying thicknesses and pore sizes, positions it as a versatile solution. Ongoing technological advancements aim to enhance precision, speed, and overall cutting efficiency.

As the demand for clean energy technologies, such as hydrogen fuel cells, continues to rise, innovations in cutting methods become increasingly vital. Ring diamond wire cutting’s potential to revolutionize the production of key components for these technologies offers exciting possibilities for a sustainable and eco-friendly future.

Conclusion

ring diamond wire cutting represents a game-changing solution for Porous Metal Cutting, with applications spanning from hydrogen fuel cells to diverse industrial uses. Its precision, efficiency, minimal environmental impact, and adaptability make it a critical player in clean energy production. As technology continues to advance, the outlook for ring diamond wire cutting remains bright, holding the promise of further improving the way we cut and process porous metals.