-Endless Diamond Wire Saw

Table of Contents

Brief Description

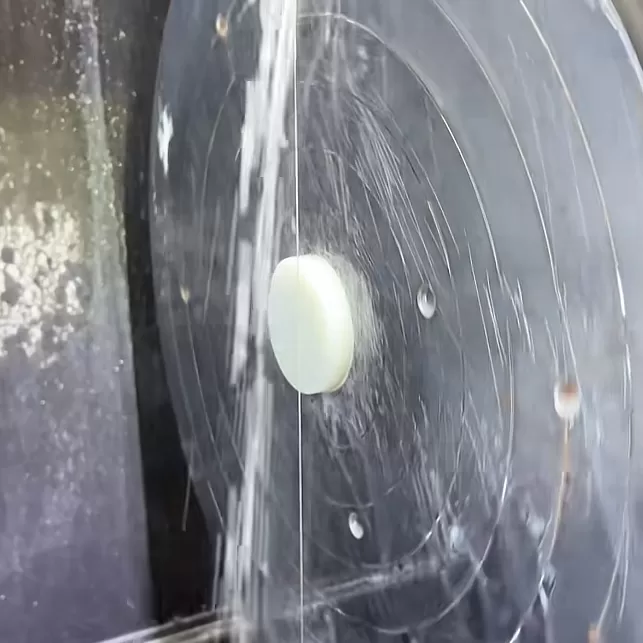

SG30-R is a cutting and polishing machine that employs endless diamond wire technology in combination with a rotary head. This innovative approach allows for the simultaneous cutting and polishing of materials, resulting in exceptionally smooth and shiny cut surfaces.

Experience a revolution in gemstone cutting with the SG30-R Gemstone Cutting Machine. Melding cutting-edge technology with traditional craftsmanship, this machine sets new standards for precision, efficiency, and versatility in gemstone processing.

Summary of the key features and benefits of the SG30-R:

1, Endless Diamond Wire Cutting:

The machine utilizes an endless diamond wire, known for its precision and durability, as the cutting tool. This wire continuously moves through the material, ensuring efficient and accurate cuts.

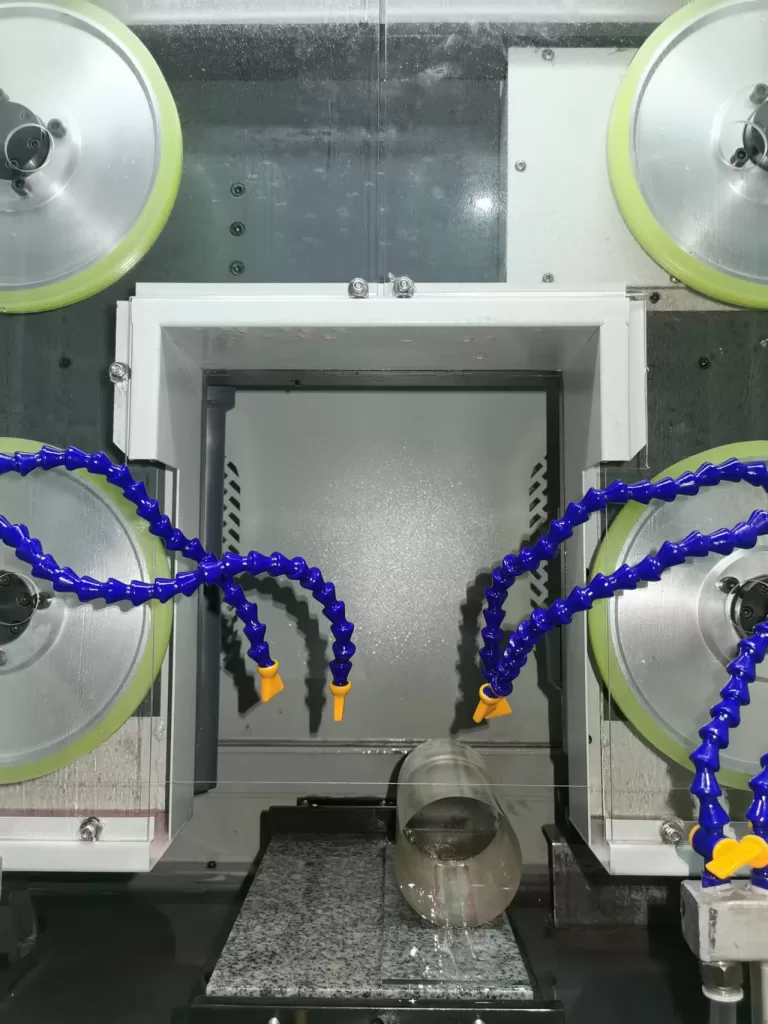

2,Rotary Head Integration:

The addition of a rotary head is a game-changer. As the wire cuts through the material, the rotary head simultaneously rotates it. This dual action not only accelerates the cutting process but also adds a polishing effect to the cut surface.

3,Simultaneous Cutting and Polishing:

The unique combination of cutting and polishing in a single machine operation streamlines the manufacturing process significantly. This results in substantial time savings, increased efficiency, and reduced production costs.

Super Smooth and Shiny Surfaces: The SG30-R excels in creating surfaces that are not only precise but also exceptionally smooth and shiny. This is especially valuable in industries where the quality of the cut surface is paramount, such as optics, electronics, and high-end manufacturing.

4,Wide Range of Applications:

This versatile machine is suitable for a variety of materials, including optical glass, quartz, and other hard substances. Its ability to create a smooth, polished finish makes it ideal for industries requiring flawless results.

5,Enhanced Productivity:

By combining cutting and polishing into a single process, the SG30-R boosts productivity, reduces manual labor, and minimizes the need for secondary finishing steps. This makes it an attractive choice for high-volume production.

6,Quality Assurance: The precision and consistency offered by the SG30-R ensure that every cut meets the highest quality standards, reducing material wastage and rework.

7, Versatile Replacement for Old Circular Saw:

When it comes to cutting gemstones, the choice between a circular saw and an endless wire saw can significantly impact the cutting process and the quality of the cut. Here’s a comparison of the differences between the two methods:

Circular Saw:

1. Precision and Accuracy:

- Limited precision, especially for intricate cuts or facet patterns.

- May result in thicker kerf width, leading to more material wastage.

2. Versatility:

- Better suited for simple cuts and shaping gemstones into basic shapes like rounds and ovals

3. Surface Finish:

- May require additional polishing steps to achieve a smooth and shiny surface.

4. Speed and Efficiency:

- Generally slower cutting speed, particularly for harder gemstone materials.

5. Material Wastage:

- Typically generates more material wastage due to the width of the blade and the cut.

6. Skill and Experience:

- Requires a certain level of skill but is relatively easier to operate compared to advanced wire saws.

Endless Wire Saw:

1. Precision and Accuracy:

- Limited precision, especially for intricate cuts or facet patterns.

2. Versatility:

- Better suited for simple cuts and shaping gemstones into basic shapes like rounds and ovals.

3. Surface Finish:

- May require additional polishing steps to achieve a smooth and shiny surface.

4. Speed and Efficiency:

- Generally slower cutting speed, particularly for harder gemstone materials.

5. Material Wastage:

- Typically generates more material wastage due to the width of the blade and the cut.

6. Skill and Experience:

- Often used by experienced lapidaries due to its precision and intricacy. Proper setup and operation require expertise.

Case Studies

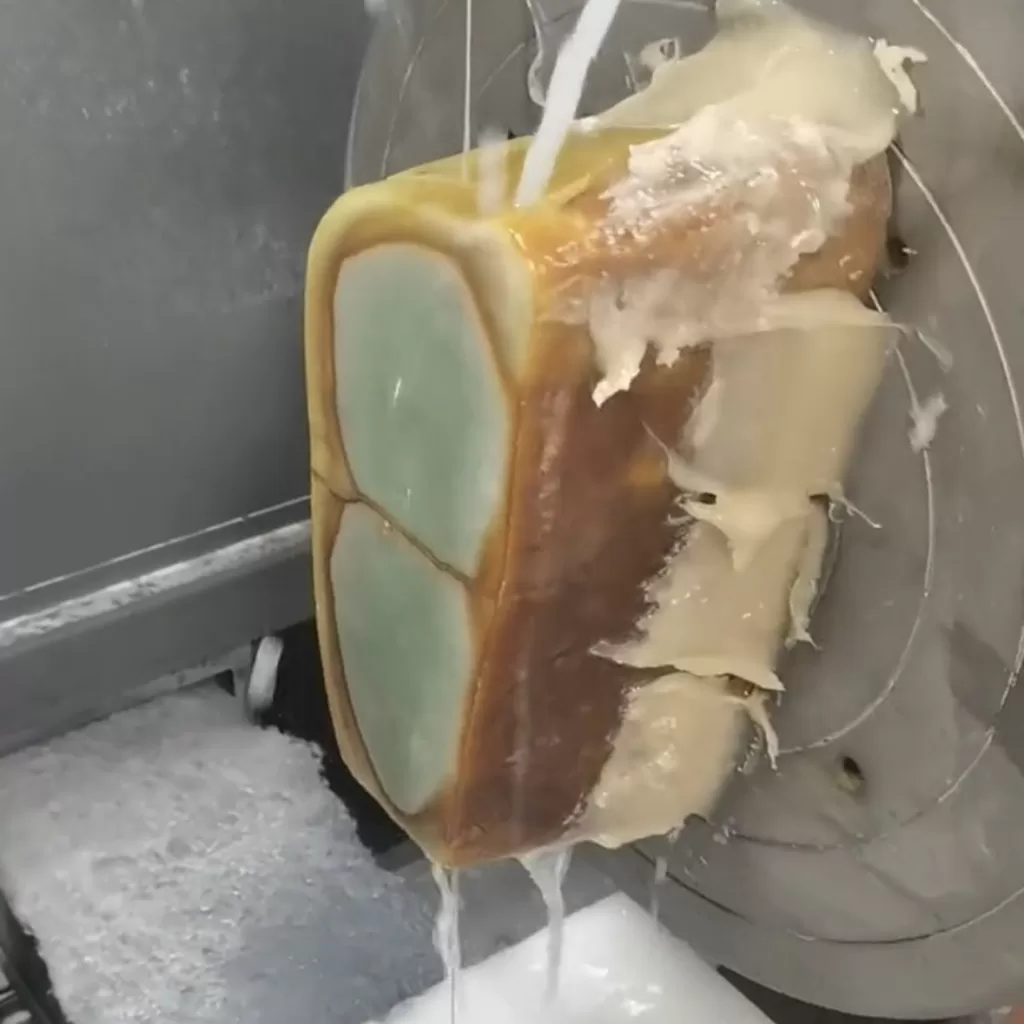

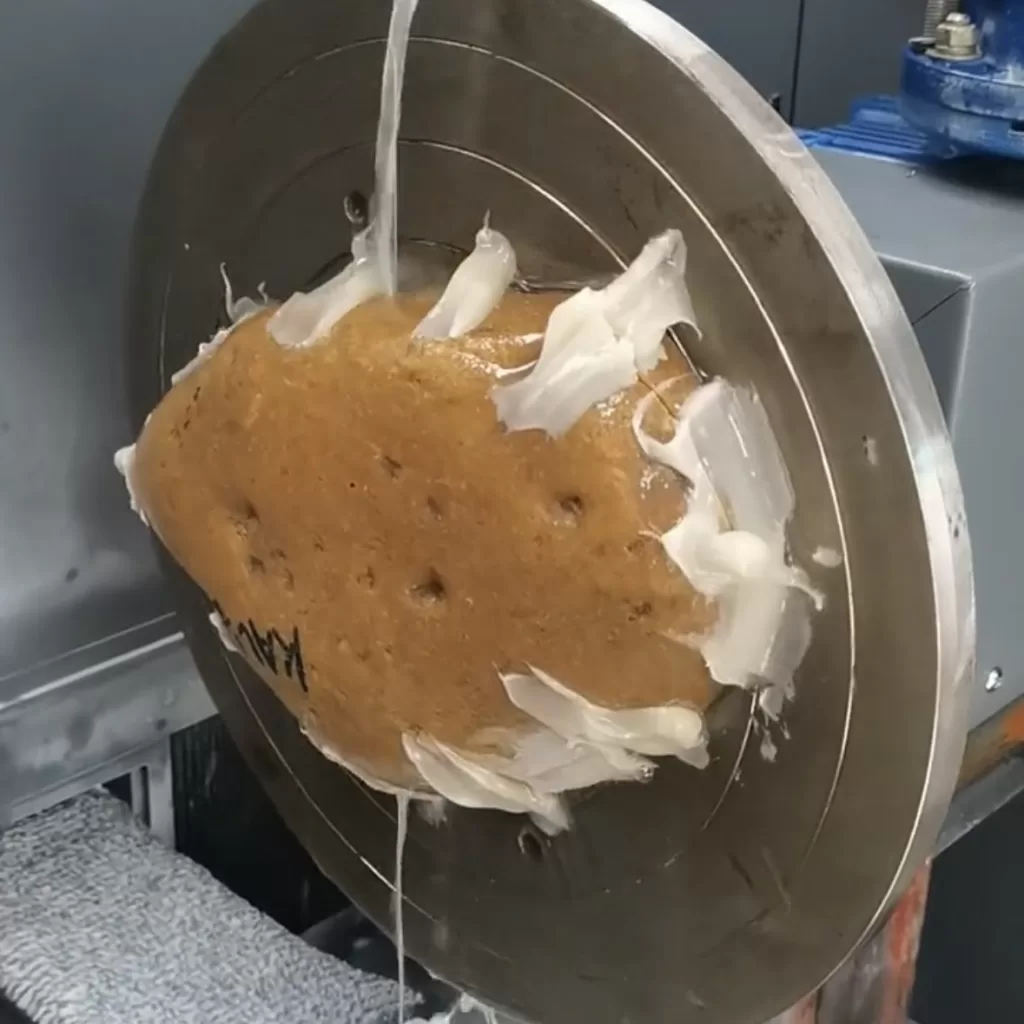

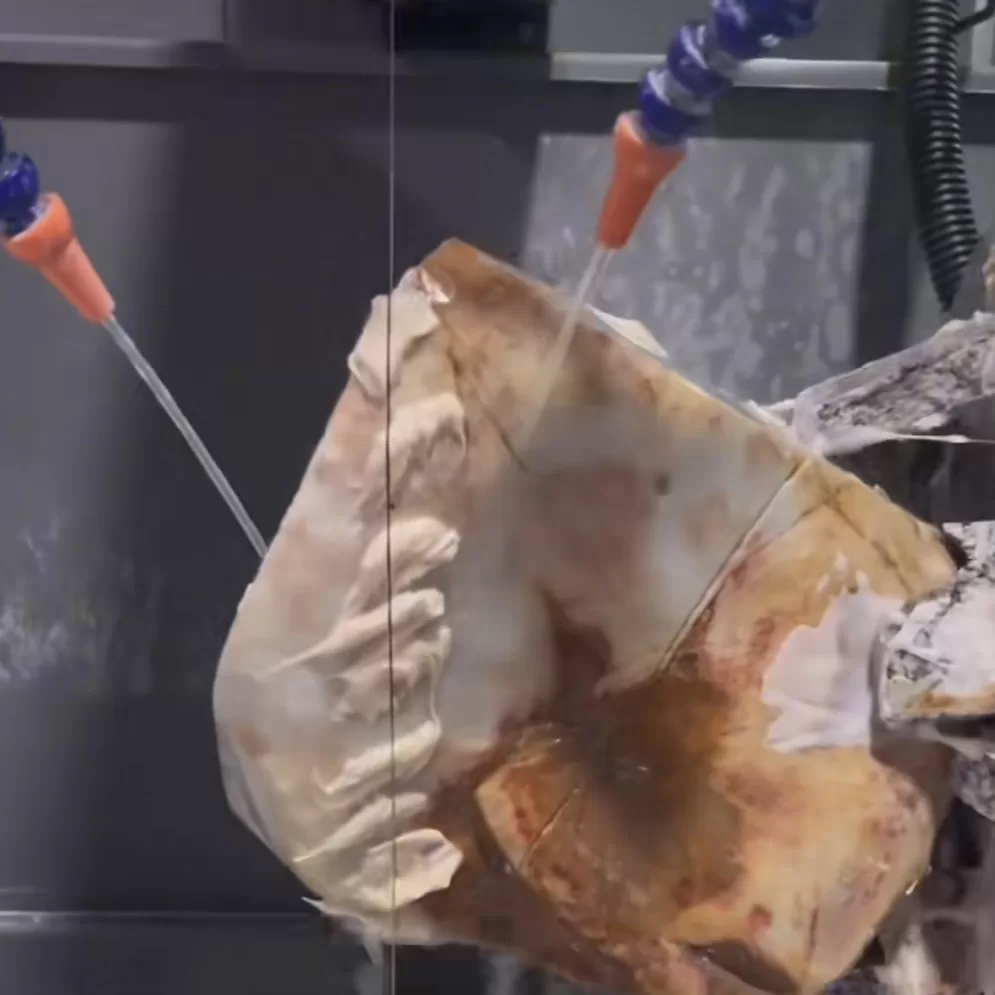

Cutting Video of successful case Gemstone Cutting Machine

Pictures of successful case Gemstone Cutting Machine

Successful application examples of SG Series in different industries and projects:

1,Magnetic industry:

this machine model can cut NefeB blocks with efficiency.

2,Gemstone Industry:

SG 20,SG25,SG30 can both used to cut gemstones with a very smaller kerf loss and much better cutting surface.such as ruby cut,jade cut,emerald cut,garnet cut,topaz cut, amethyst cut,turquoise cut and coral cut.

3,Meteorite industry:

SG 20,SG25,SG30 can both used to cut Meteorite with a very smaller kerf loss and very fast cutting speed.such as Iron Meteorites cut,Stone Meteorites cut,Stony-Iron Meteorites cut,Carbonaceous Chondrites cut,Shock-Metamorphosed Meteorites cut and Metallic Meteorites cut.

4,University and Lab :

SG series machine are quite small, it’s like a refrigerator but with all needed function, so it’s quite popular to be a school and lab machinery.

Product Detail

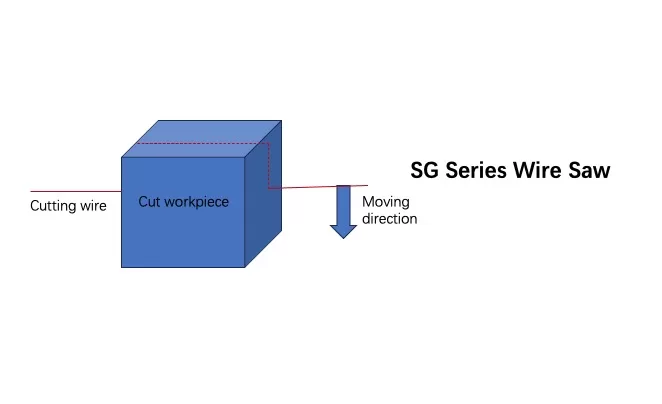

The working principle of this Optical Glass Cutting Machine

1,Cutting Line Orientation:

The cutting wire is positioned parallel to the ground, while the glass rod or blocks are parallelly placed on the loading platform.

2,High-Speed Cutting Wire Motion:

The cutting wire moves at high speed along its circular path, maintaining constant tension and maintaining its sharpness during the cutting process.

3,Gantry Cutting:

As the cutting wire moves, whole wheel system move from top to bottom, allowing for gantry cutting of the glasses.

4,Control and Precision:

The cutting machine is equipped with a control system that ensures precise movement of the cutting wire and the loading platform. The control system allows for accurate positioning and motion control, resulting in consistent and high-quality cuts.

Typical specifications for this Gemstone Cutting Machine:

Machine Spec

1, Machine Dimension: L1000 mm*W880 mm*H1800 mm

2 Power:3kw 220V

3 Motor speed:2100 RMP

4 Total Weight:450 KG

5 loading capacity: 100 KG

6 Max linear speed:38 m/s

Material Dimension

Material dimension : smaller than L300 mm*W300 mm*H300 mm

Support and Services

Maintenance and Servicing:

We provide comprehensive maintenance and servicing services to ensure the long-term reliable operation of the silicon rod cutting equipment. Our dedicated maintenance team possesses extensive experience and technical knowledge to promptly respond to and resolve equipment issues. We made check list to conduct regular preventive maintenance, inspecting and adjusting critical components to ensure optimal performance and accuracy. Whether it’s routine maintenance or emergency repairs, we are committed to delivering fast and efficient servicing to minimize equipment downtime.

and we have local service available in Canada.

Training:

We offer comprehensive training programs designed to empower customers with in-depth knowledge and proficiency in operating and maintaining the silicon ingot cutting machine. Our training courses cover basic equipment operation, safe usage practices, maintenance procedures, and troubleshooting. Customized training content and flexible training methods, including on-site training, remote training, and provision of training materials, are provided based on customer needs and backgrounds. Through our training programs, customers can enhance their operational skills, improve equipment efficiency, and ensure long-term reliable performance.

Consulting:

We provide professional consulting services to meet customer needs regarding silicon ingot cutting machine and related areas. Our team of experts offers tailored advice and solutions based on specific requirements. Whether it’s equipment selection, process optimization, production line layout, or quality control, we collaborate with customers, providing professional guidance and technical support. We strive to establish long-term partnerships with customers, working together to address various technical and engineering challenges, meet their needs, and achieve mutual success.

Perfectly Solve Your Cutting Problems

Vertical wirecutting machine can be adapted to all cutting scene with an satisfying performance

We accept sample cutting service, leave your information and enjoy our free cutting test service →

-1024x685.jpg)

Our Services

- Fast after-sales service

7 Days 24 Hours online

- Professional and experienced

Engineers have 5 years experience in this Industry

- High quality

Machine with International brands components and precision manufacturing

- Good Reputation

Shine Wirecut With high-quality products, stable use of effects, perfect, meticulous, fast after-sales service won the trust of customers

-1536x1024.jpg)

-1-1536x886.jpg)

.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1-1536x861.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1536x1024.jpg)

-1536x1024.jpg)