Endless Diamond Wire Saw Machine

Table of Contents

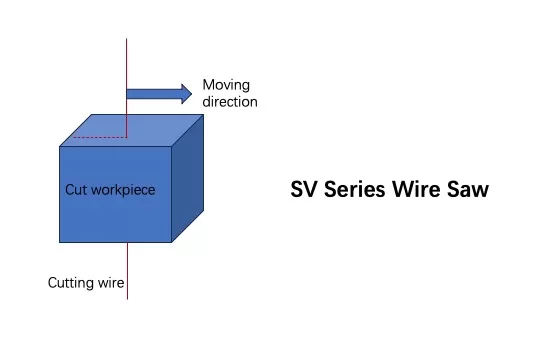

SV Series Endless Wire Saw

This series are vertical wire cutting machine , endless diamond wire cuts from left to right. It has x axis and y axis moving automatically , z axis is a fixed distance .

Some key advantages of using a vertical wire cutting machine:

Precise Vertical Cuts:

Vertical wire cutting machines excel at producing accurate cuts in the vertical direction. This precision is crucial for industries that require intricate components and precise shapes, such as electronics, aerospace, and medical device manufacturing.

Minimal Material Waste:

Vertical wire cutting minimizes material waste due to the focused and controlled cutting path. This efficiency is particularly valuable when working with expensive or rare materials, helping to reduce production costs.

Reduced Mechanical Stress:

Vertical cutting exerts less mechanical stress on the workpiece compared to other cutting methods. This is advantageous when working with delicate materials, ensuring minimal distortion or damage during the cutting process.

Intricate Shapes and Contours:

The ability to precisely control the wire’s movement allows for the creation of intricate shapes and contours that might be challenging with other cutting techniques. This is valuable in industries that require complex geometries.

Minimal Heat Generation:

Vertical wire cutting generates less heat compared to other methods. This is important for materials that are sensitive to high temperatures, preventing distortion or other thermal effects.

Ease of Automation:

Vertical wire cutting machines can be easily integrated into automated manufacturing processes. This allows for consistent and repeatable cuts, improving overall production efficiency.

Multiple Material Compatibility:

Vertical wire cutting machines can be used on a wide range of materials, including metals, ceramics, composites, and more. This versatility makes them suitable for various industries.

Prototyping and Small Batch Production:

The precision and flexibility of vertical wire cutting make it ideal for prototyping and small batch production. This allows for efficient testing and development of new products.

Clean and Burr-Free Cuts:

Vertical wire cutting often produces clean cuts without the need for secondary finishing processes. This saves time and ensures high-quality finished products.

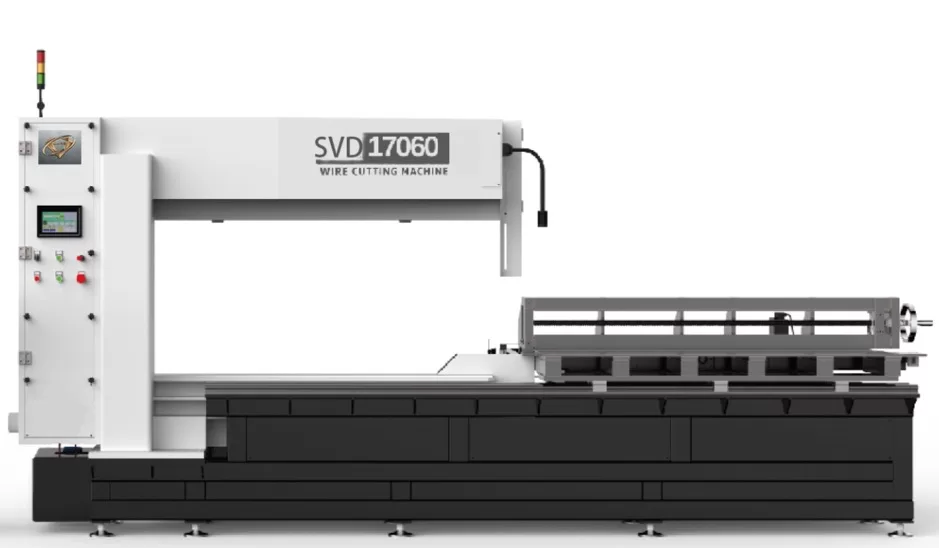

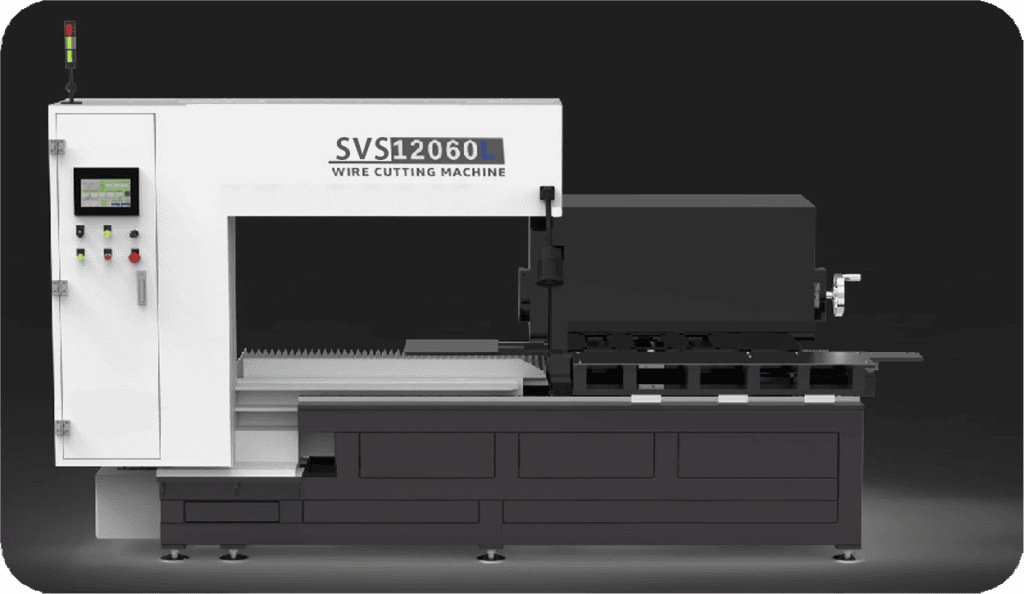

There are a lot models of SV series based on different size

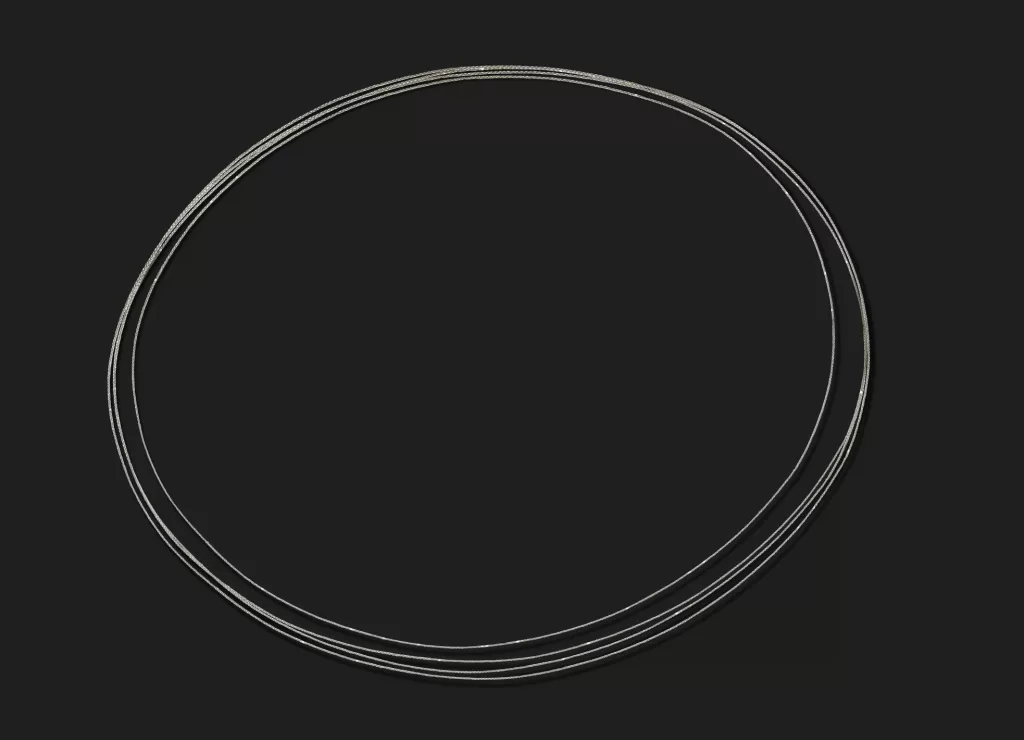

Endless Diamond Wire Cutting Machine

Wire cut solution for glass, graphite, silicon, sapphire, ceramic…

Video shows how SV series endless diamond wire saw machine works

Introducing All Our Machine Series: SV, SH, SG, SVO, and SVC

Our machine series, SV, SH, SG, SVO, and SVC, encapsulate precision engineering and tailored solutions. Each series is meticulously designed to address specific cutting needs and industries.

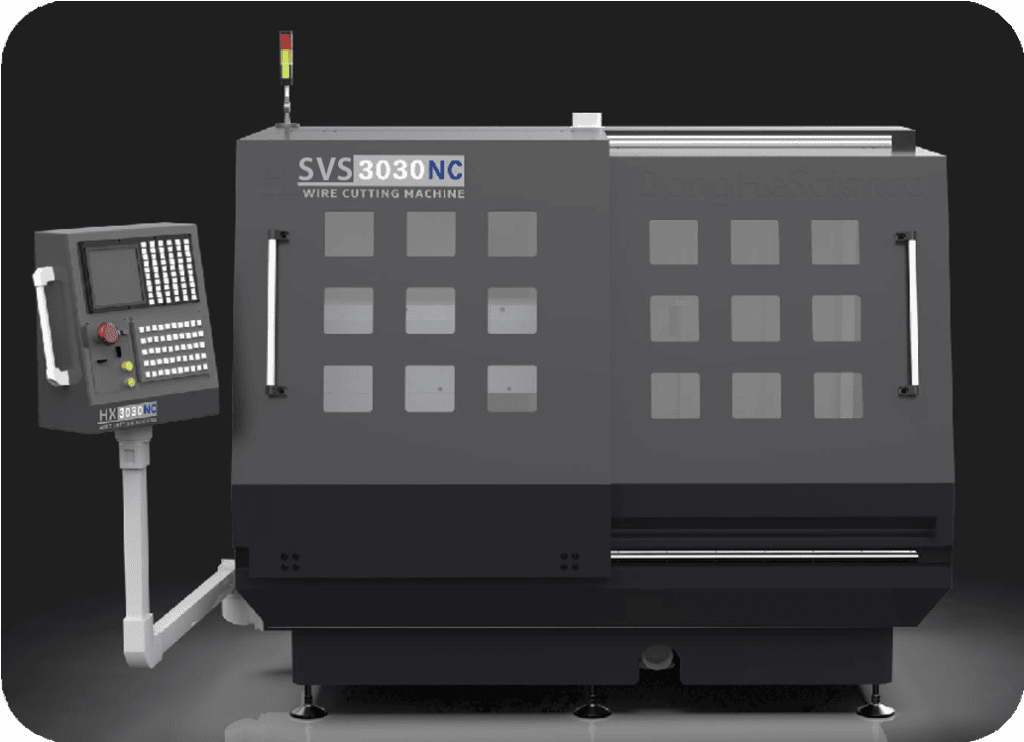

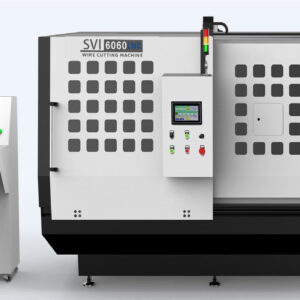

SV Series: Vertical Structure

The SV series excels in vertical cutting applications. Whether it’s semiconductor wafers or photovoltaic cells, this series ensures accurate vertical cuts.

SH Series: Horizontal Structure

The SH series is engineered for horizontal cutting tasks like glass and ceramics. It sets high standards for precision in horizontal cuts.

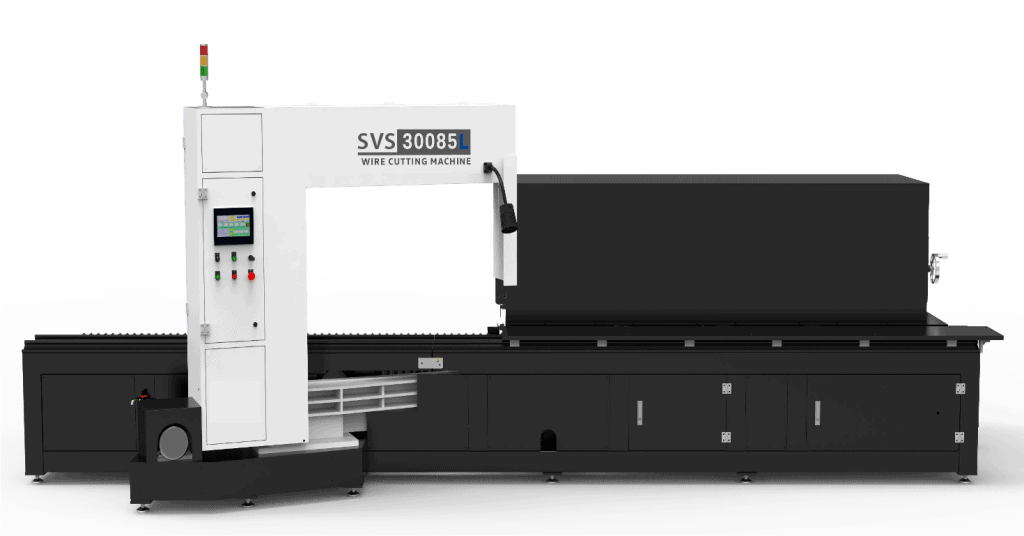

SG Series: Gantry Structure

The SG series excels in gantry cutting tasks. It delivers precise cuts for intricate components, maintaining accuracy on a larger scale.

SVO Series: Vertical Structure with Open-End Diamond Wire

The SVO series employs open-end diamond wire for versatile cutting, catering to intricate designs and expansive projects.

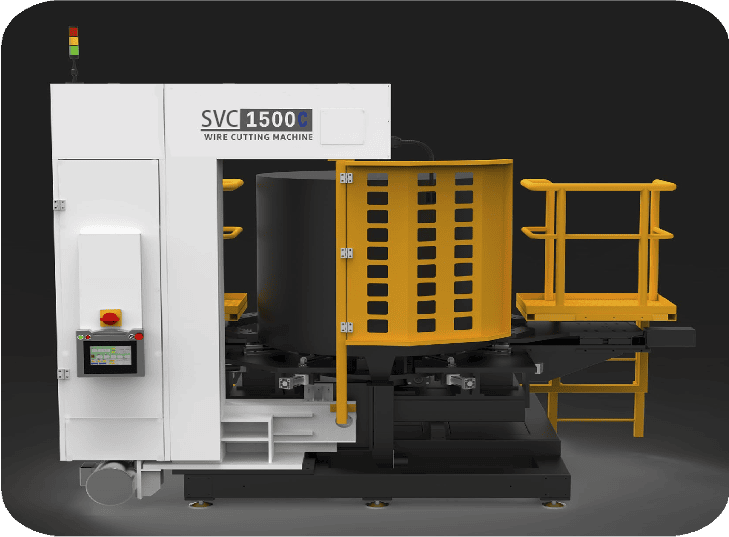

SVC Series: Vertical Structure with Connectable Diamond Wire

The SVC series introduces connectable endless diamond wire technology. It offers limitless cutting dimensions, suitable for unique industrial demands.

Each series reflects our commitment to precision, efficiency, and customized solutions.

#PrecisionEngineering #CustomizedCutting #Innovation #VerticalCut #HorizontalCut #GantryCut #OpenEndDiamondWire #ConnectableDiamondWire#endlessDiamond Wire Saw Machine

Perfectly Solve Your Cutting Problems

Horizontal wire cutting cut can be adapted to all cutting scene with an satisfying performance

We accept sample cutting service, leave your information and enjoy our free testing service →

-1024x685.jpg)

Our Services

- Fast after-sales service

7 Days 24 Hours online

- Professional and experienced

Engineers have 5 years experience in this Industry

- High quality

Machine with International brands components and precision manufacturing

- Good Reputation

Shine Horizontal wire cutting With high-quality products, stable use of effects, perfect, meticulous, fast after-sales service won the trust of customers

Horizontal Wire Cutting Machine Details

Cut Graphite ,Cut Glass, Cut Quartz ,Cut Meteorite

-1536x1024.jpg)

-1-1536x886.jpg)

.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1-1536x861.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1536x1024.jpg)

-1536x1024.jpg)

Sourcing Wire Cutting Machine From Shine Wire Cut

- For Factory Owners

We have worked with different companies to take their ideas from conception to realisation of their efficiency and a cutting solutions. Whether it’s a customised function or a customised look, we can provide you with the perfect processing solutions.

- For Distributors

Our modern production plant allows us to offer great quality options to appeal to your target customers. As a distributor you can trust that our streamlined manufacturing processes are here to provide you with the best machine in the market.

- For National Agents

Being one of the most famous endless diamond wire cutting Machine manufacturing companies, we offer the best quality products at a significantly low cost. This allows us to work with you to ensure that you get to also extend great prices to your customers.

Why Choose Shine Wire Cut

At Shine, our mission is to be globally competitive in a growthing new market. Our goal is to be the global supplier of choice for endless wire cut machines. Through innovation, we can provide better products to our customers. We help more companies to further improve productivity, reduce labor costs and meet production demands.