-Replace Band Saw

Table of Contents

Brief Description

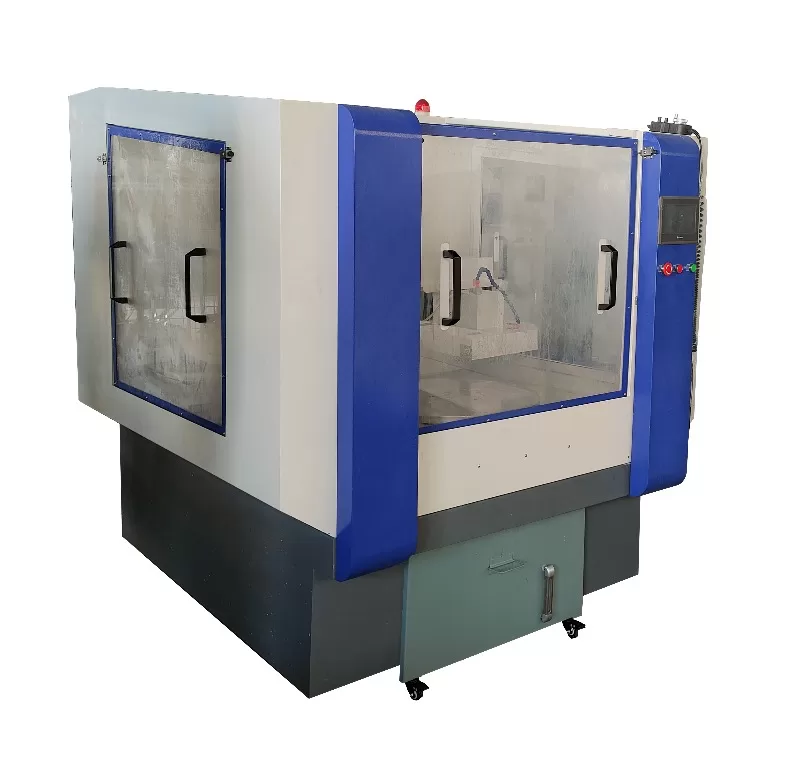

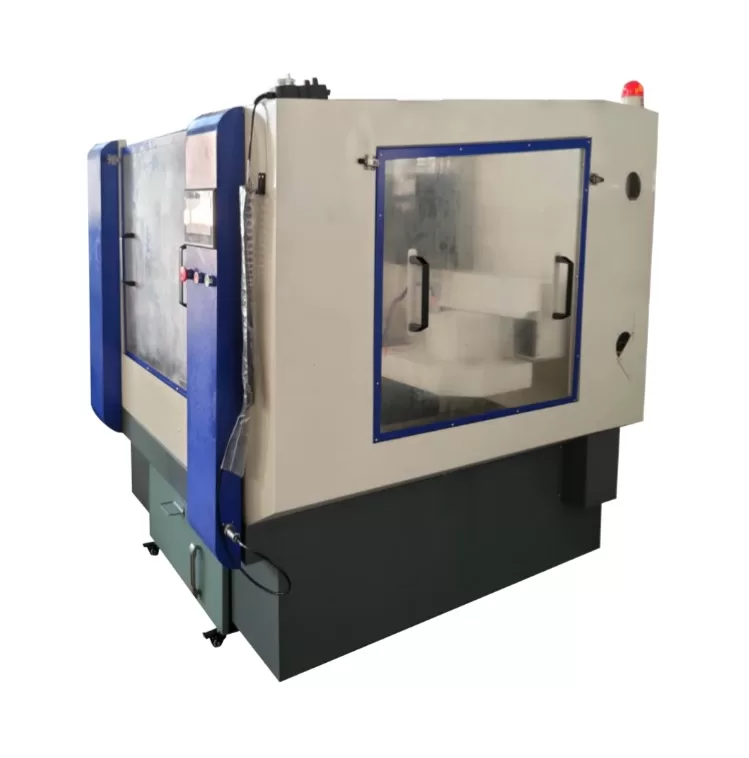

Step into a new era of quartz glass cutting with our cutting-edge Endless Wire Saw Model SH60. Designed specifically for large-size quartz glass cutting, this remarkable innovation reshapes the boundaries of cutting speed, efficiency, and versatility.

Model SH60 has an endless diamond wire that can move in a single direction without the need for reversing. The closed diamond wire enables high linear speeds, reaching even up to 60 m/s. As a result, it allows for fast cutting speeds and maintaining superior cutting surface quality.

This machine is a horizontal cutting wire saw, the has a workpiece station which you can put big and heavy material easily with a fork or ship crane.it’s quite easy to operate.

Unique features, performance, and advantages of quartz cutting machine

1,Unprecedented Cutting Speed:

The SH60 stands as a beacon of cutting speed advancement. Unlike traditional inner diameter saws or bandsaws used for quartz cutting machine, our revolutionary endless wire saw technology enables lightning-fast cuts. since the linear speed of this saw can be up to 60m/s, the cutting wire would be very sharp..

2,Limitless Cutting Scope:

Gone are the days of size limitations when it comes to quartz glass cutting. The SH60’s innovation lies in its ability to cut quartz glass without size restriction, The cutting tool has no limitations on the size of the workpiece.this machine series has different size for different material range,the biggest workpiece it can cut is diameter 1.5 m.

3,Precision Beyond Compare:

Precision is at the core of the SH60’s design. With its state-of-the-art endless wire technology, this machine offers immaculate precision in every cut. Whether you’re working with large sections or intricate designs, the SH60 ensures flawless accuracy and exacting dimensions.

Cut Quality Redefined:

The SH60’s cutting-edge technology doesn’t just elevate speed; it redefines cutting surface quality, cutting wire running in one direction and the workpiece rotary at the same time .The cutting process is accompanied by grinding, resulting in a very smooth cutting surface.

Adaptability and Innovation:

The SH60 is a statement of adaptability and innovation. Its advanced controls and customizable settings cater to a diverse range of cutting projects, making it the go-to solution for large-scale quartz glass cutting. Whether you’re producing monumental pieces or intricate components, the SH60 delivers uncompromised results every time.

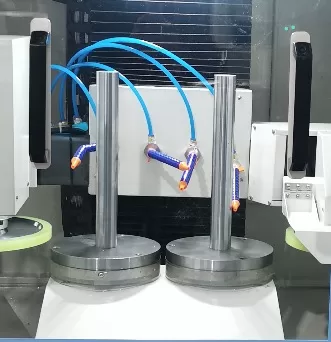

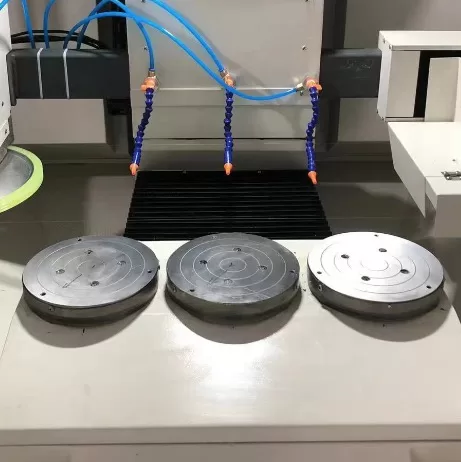

SH60-R

SH60-2R

SH60-3R

Get In Touch

Case Studies

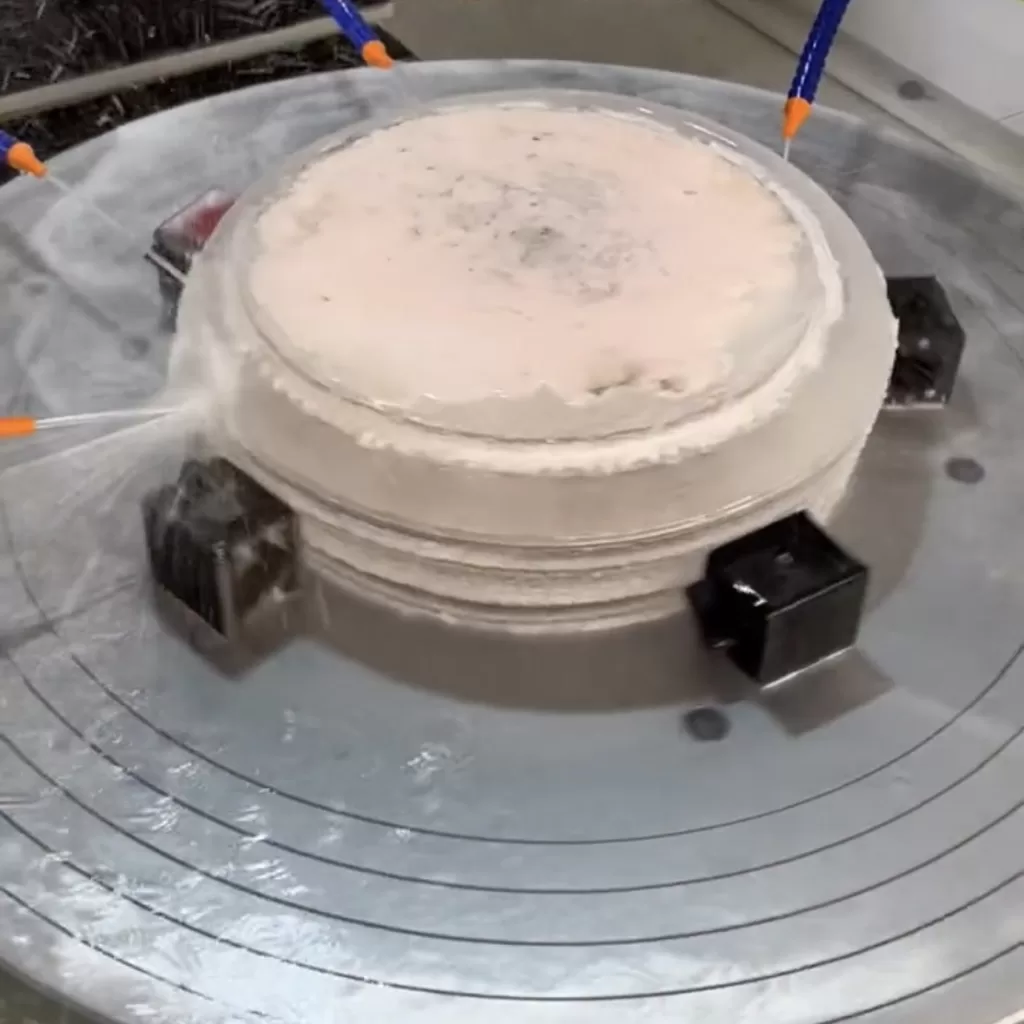

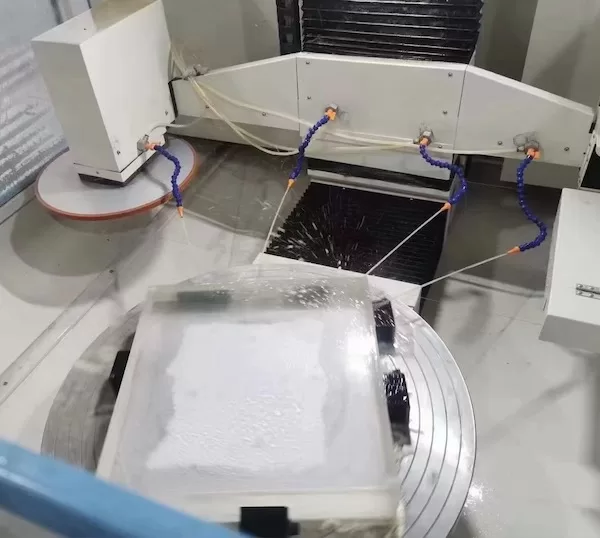

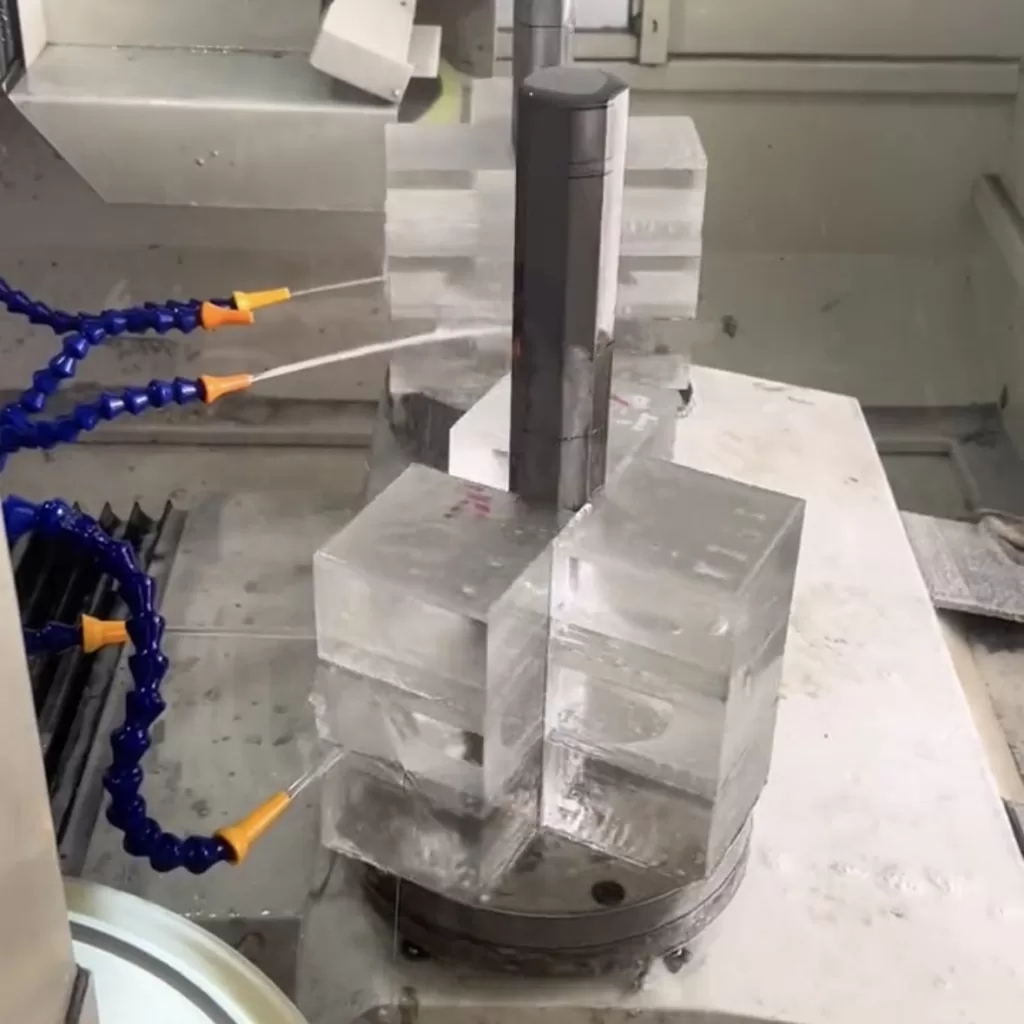

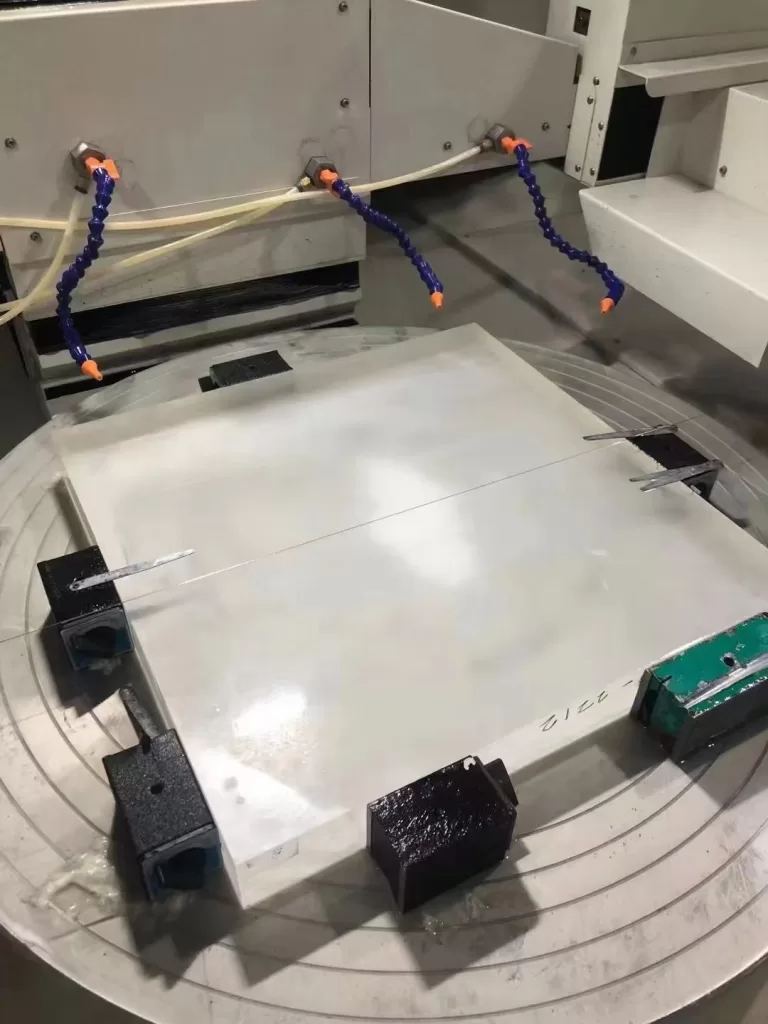

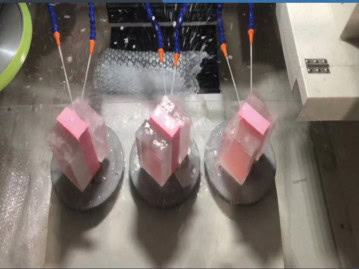

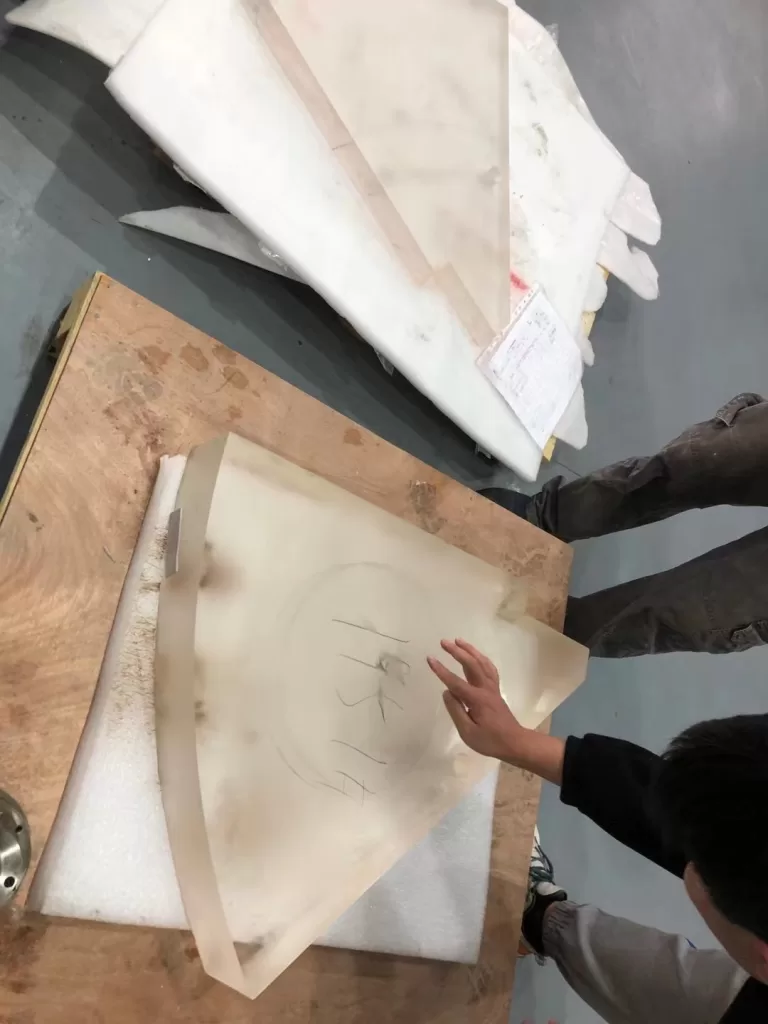

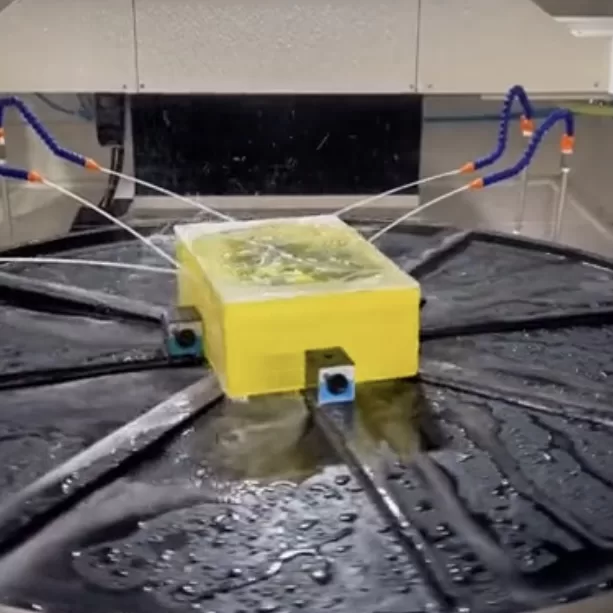

Cutting Video of successful case Quartz & ceramic Cutting Machine

Pictures of successful case Optical Glass Cutting Machine

Successful application examples of SH Series in different industries and projects:

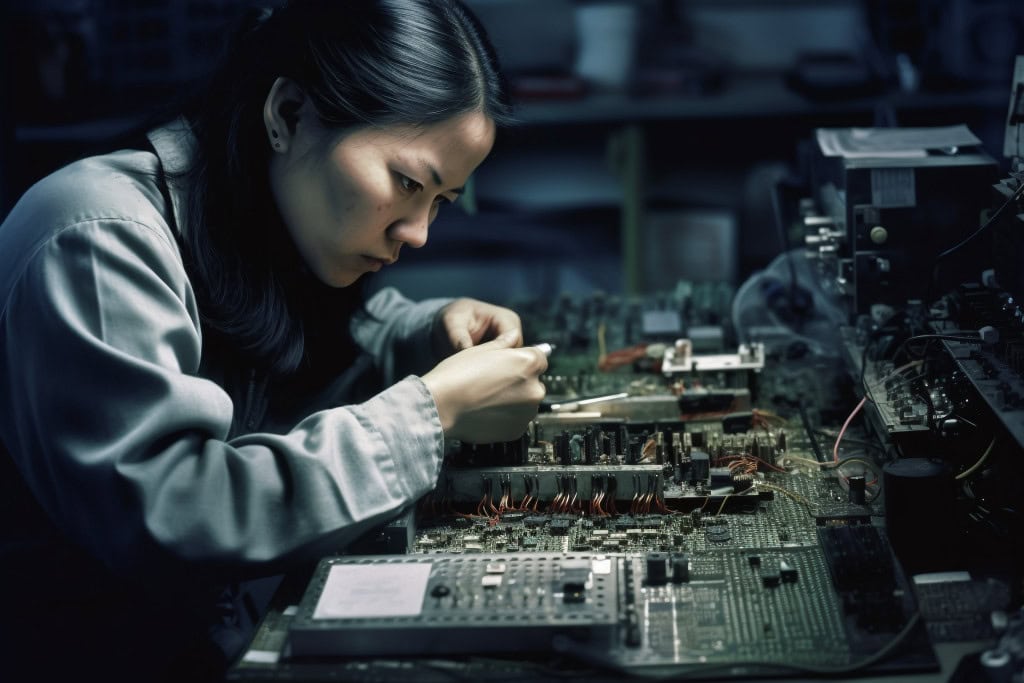

Case 1: Electronics Manufacturer

Application: Client specializes in manufacturing high-precision quartz components used in various electronic devices. They integrated the diamond wire saw into their production line to cut quartz substrates used in oscillators and resonators. The precision and efficiency of the saw allowed them to produce high-quality components with minimal material waste. This led to improved product performance and reliability, enhancing their competitiveness in the market.

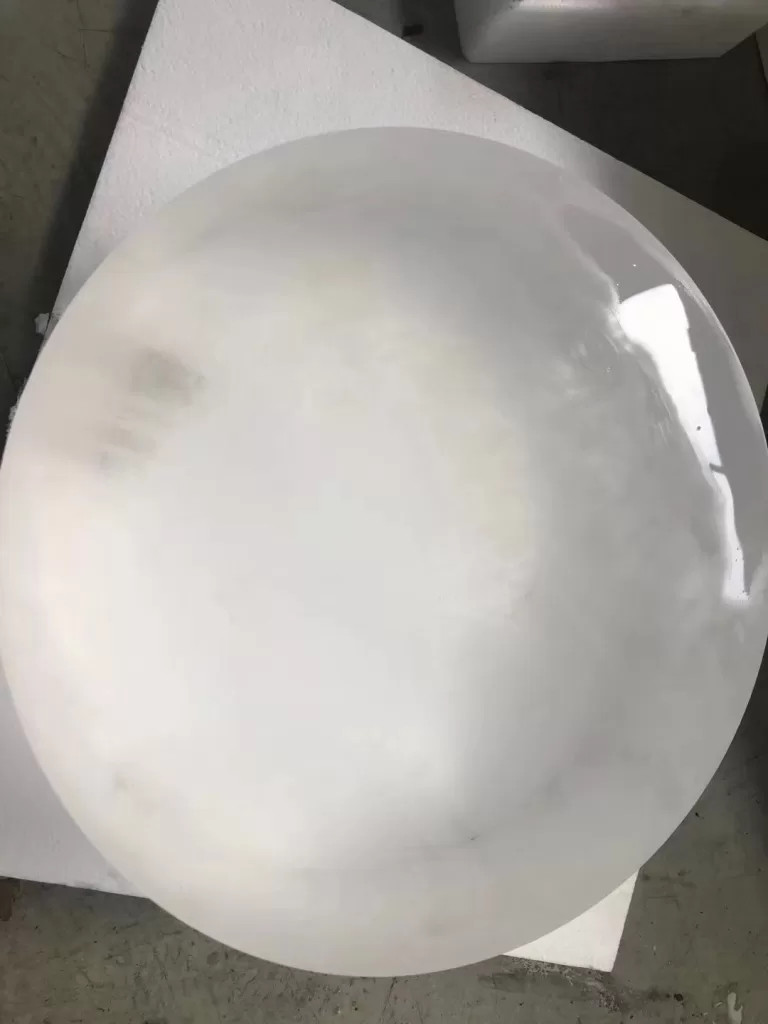

Case 2: Optical Equipment Manufacturer

Application: Client produces high-precision optical lenses and components made from quartz. The diamond wire saw was utilized to achieve smooth and accurate cuts of quartz blocks, essential for creating high-quality optical lenses. The company experienced a significant improvement in the clarity and precision of their optical products, meeting the stringent requirements of the optical industry and expanding their customer base.

Case 3: Solar Panel Manufacturer

Application: Client focuses on manufacturing photovoltaic cells and solar panels. They used the diamond wire saw to slice quartz for solar panels, ensuring uniform thickness and high precision. This led to enhanced efficiency and performance of their solar panels, reducing production costs and increasing their market share in the renewable energy sector.

Case 4: Research and Development Laboratory

Application: Client’s Research Institute conducts cutting-edge research on new materials. They adopted the diamond wire saw for precise cutting of quartz samples used in their experiments. The saw’s ability to make fine, accurate cuts with minimal surface roughness was crucial for their research, enabling detailed analysis and development of new quartz-based materials.

Case 5: Semiconductor Manufacturer

Application: Client manufactures semiconductor devices that require high-purity quartz components. The diamond wire saw was employed to cut quartz wafers used in semiconductor fabrication. The precision cutting capability of the saw ensured high-quality quartz wafers with minimal defects, leading to improved performance of their semiconductor devices and higher production yields.

The diamond wire saw for quartz is a versatile and high-precision cutting tool that serves a wide range of industries, including electronics, optics, solar energy, research, and semiconductors. These case studies demonstrate the saw’s effectiveness in delivering superior cutting performance, enhancing product quality, and driving operational efficiency across various applications.

Product Detail

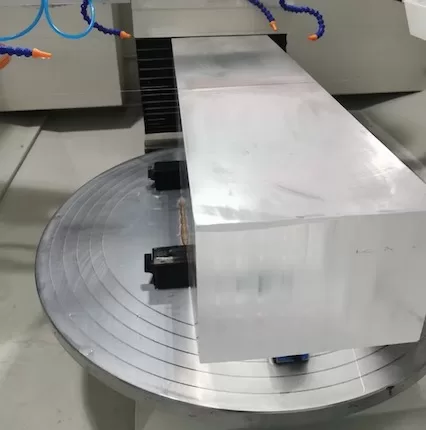

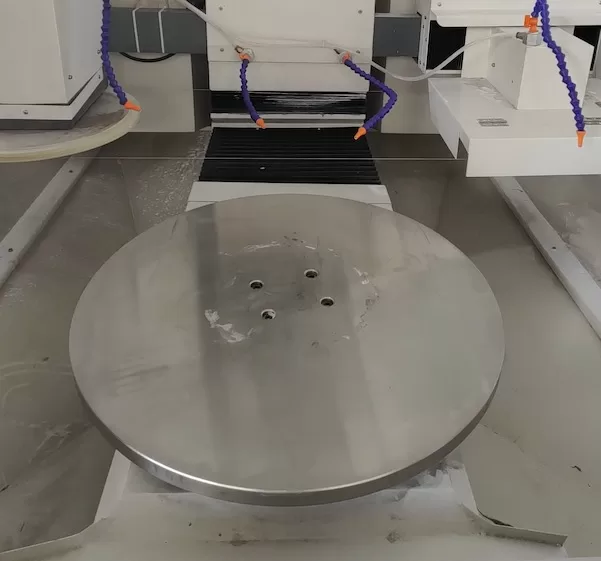

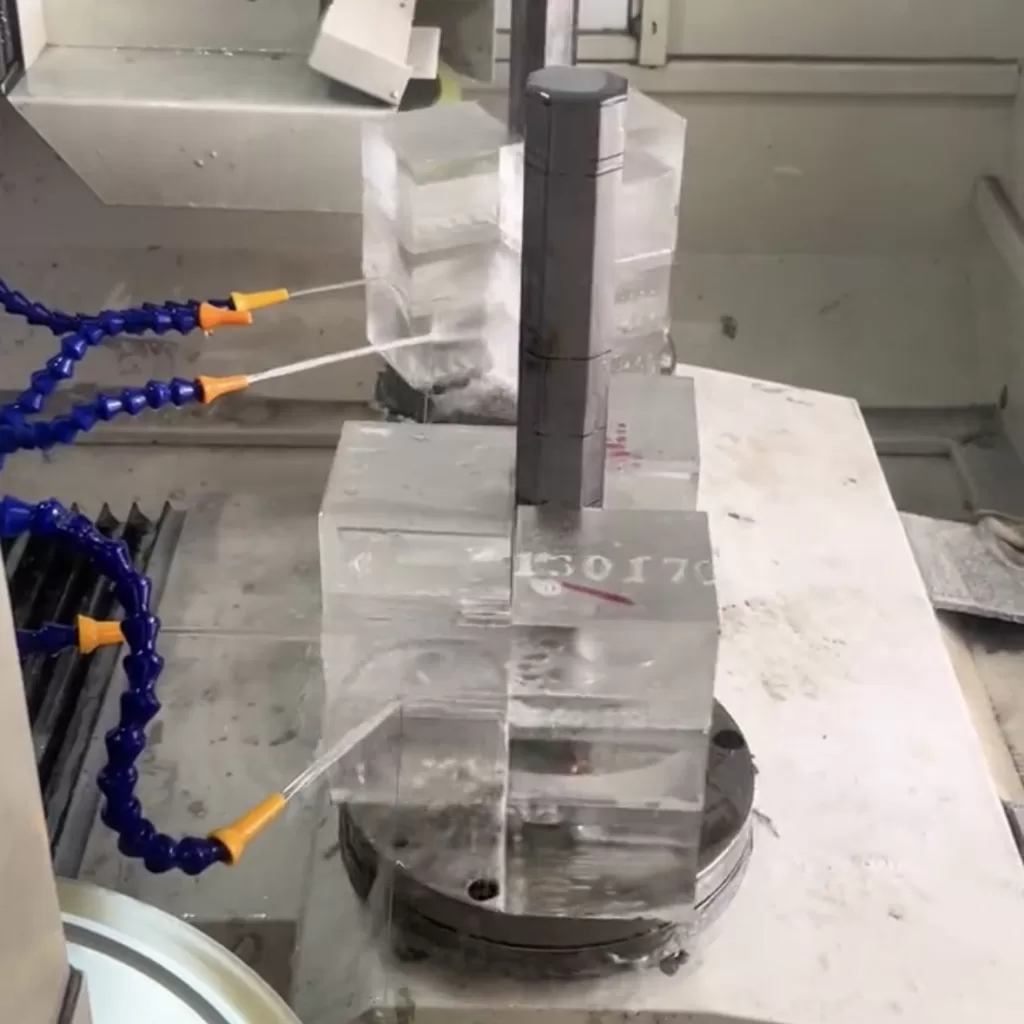

The working principle of this quartz ingot Cutting Machine

1,Cutting Line Orientation:

The cutting wire is positioned parallel to the ground, while the quartz ingot or blocks are parallelly placed on the loading platform.

2,High-Speed Cutting Wire Motion:

The cutting wire moves at high speed along its circular path, maintaining constant tension and maintaining its sharpness during the cutting process.

3,Horizontal Cutting:

As the cutting wire moves, whole wheel system move from forward to backward, allowing for horizontal cutting of the quartz.

4,Control and Precision:

The cutting machine is equipped with a control system and a hand controller that ensures precise movement of the cutting wire and the loading platform. The control system allows for accurate positioning and motion control, resulting in consistent and high-quality cuts.

Typical specifications for this Optical Glass Cutting Machine:

Machine Spec

1, Machine Dimension: L1650 mm*W1650 mm*H1700 mm

2 Power:4 kw 220V

3 Motor speed:2100 RMP

4 Total Weight:1200 KG

5 loading capacity: 400 KG

6 Max linear speed:60 m/s

Material Dimension

Material dimension : smaller than dia 600mm

Same Machine Structure there are bigger machine size for your choice

Support and Services

Maintenance and Servicing:

We provide comprehensive maintenance and servicing services to ensure the long-term reliable operation of the silicon rod cutting equipment. Our dedicated maintenance team possesses extensive experience and technical knowledge to promptly respond to and resolve equipment issues. We made check list to conduct regular preventive maintenance, inspecting and adjusting critical components to ensure optimal performance and accuracy. Whether it’s routine maintenance or emergency repairs, we are committed to delivering fast and efficient servicing to minimize equipment downtime.

and we have local service available in Canada.

Training:

We offer comprehensive training programs designed to empower customers with in-depth knowledge and proficiency in operating and maintaining the silicon ingot cutting machine. Our training courses cover basic equipment operation, safe usage practices, maintenance procedures, and troubleshooting. Customized training content and flexible training methods, including on-site training, remote training, and provision of training materials, are provided based on customer needs and backgrounds. Through our training programs, customers can enhance their operational skills, improve equipment efficiency, and ensure long-term reliable performance.

Consulting:

We provide professional consulting services to meet customer needs regarding silicon ingot cutting machine and related areas. Our team of experts offers tailored advice and solutions based on specific requirements. Whether it’s equipment selection, process optimization, production line layout, or quality control, we collaborate with customers, providing professional guidance and technical support. We strive to establish long-term partnerships with customers, working together to address various technical and engineering challenges, meet their needs, and achieve mutual success.

Perfectly Solve Your Cutting Problems

Vertical wirecutting machine can be adapted to all cutting scene with an satisfying performance

We accept sample cutting service, leave your information and enjoy our free cutting test service →

-1024x685.jpg)

Our Services

- Fast after-sales service

7 Days 24 Hours online

- Professional and experienced

Engineers have 5 years experience in this Industry

- High quality

Machine with International brands components and precision manufacturing

- Good Reputation

Shine Wirecut With high-quality products, stable use of effects, perfect, meticulous, fast after-sales service won the trust of customers

-1536x1024.jpg)

-1-1536x886.jpg)

.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1-1536x861.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1536x1024.jpg)