Ключевые слова: Alumina Machining,Circular Diamond Wire

Оглавление

Введение

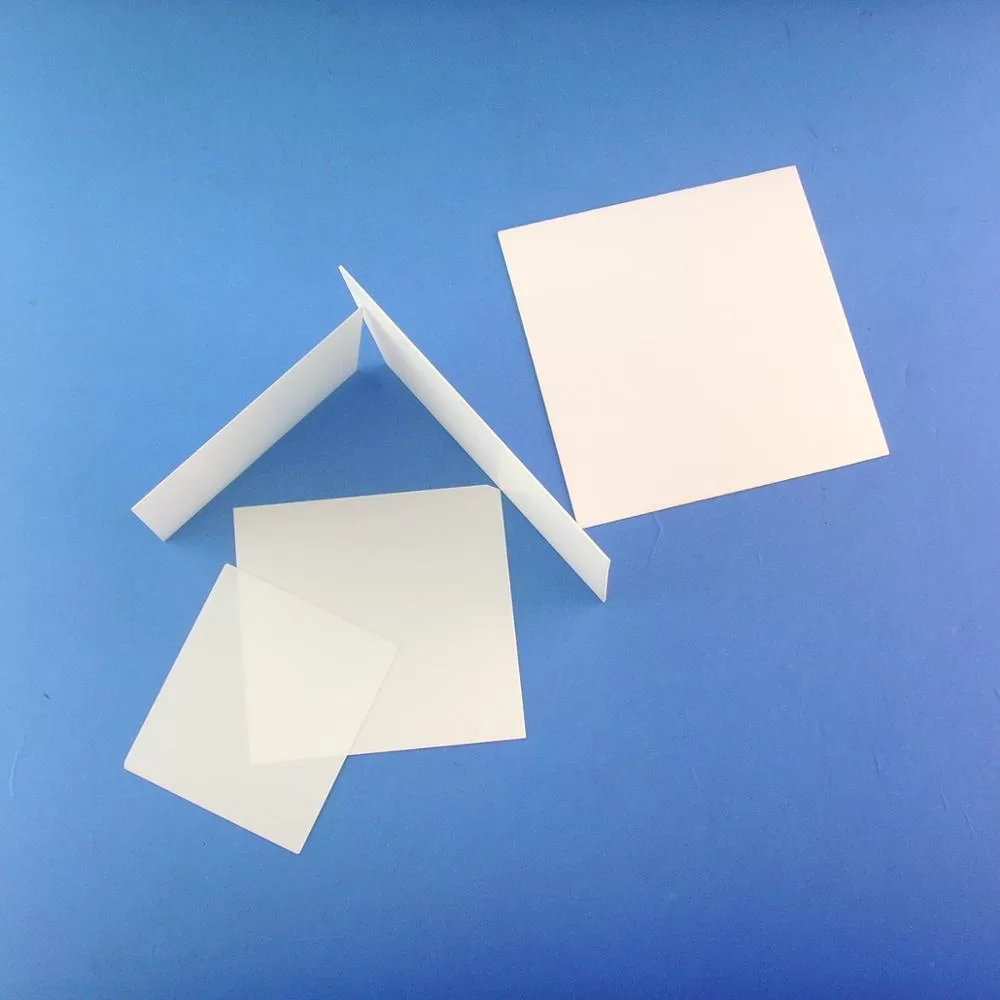

Alumina, also known as aluminum oxide, is an engineering ceramic widely used in modern manufacturing. Its exceptional properties include high hardness, wear resistance, high-temperature stability, and electrical insulation. As a result, it finds applications across various industries such as electronics, medical, aerospace, and chemical engineering. However, due to its high hardness and brittleness, alumina machining has always been a challenge. Traditional cutting methods often led to material damage and wastage. In recent years, circular diamond wire cutting technology has emerged, revolutionizing the machining of alumina.

Properties and Applications of Alumina

Alumina is a ceramic material primarily composed of aluminum oxide (Al2O3). Its characteristics include:

- Высокая твердость: Alumina possesses extremely high hardness, second only to diamond.

- Wear Resistance: Thanks to its exceptional hardness, alumina exhibits outstanding wear resistance.

- High-Temperature Stability: Alumina can maintain its physical and chemical properties in high-temperature environments, making it suitable for elevated-temperature applications.

- Электрическая изоляция: It serves as an excellent electrical insulator, making it valuable in the manufacture of electronic components.

Alumina plays a vital role in manufacturing electronic ceramics, medical implants, aerospace engine components, and chemical processing equipment, among other fields.

The Alumina Machining methods

also known as aluminum oxide, is a process used to shape or separate this ceramic material into desired forms or sizes. There are several methods for cutting alumina, each with its own advantages and limitations. Some common cutting methods for alumina include:

- Diamond Blade Cutting: This method involves using a diamond-coated blade, saw, or wheel to cut through alumina. Diamond is an extremely hard material and can effectively cut through the hardness of alumina ceramics. It provides relatively clean cuts and can be suitable for various alumina machining applications.

- Лазерная резка: Laser cutting is a precise and non-contact method of cutting alumina. A focused laser beam is directed at the material, vaporizing or melting it to create precise cuts. This method is ideal for intricate shapes and fine details.

- Гидроабразивная резка: Water jet cutting uses a high-pressure stream of water mixed with abrasive materials to cut through alumina. It’s a versatile method that doesn’t generate significant heat, making it suitable for brittle materials like alumina. Water jet cutting can handle various thicknesses and shapes.

- Plasma Cutting: Plasma cutting uses a jet of ionized gas (plasma) to cut through alumina. It’s a high-temperature method suitable for thick alumina sections. However, it may not provide the precision needed for intricate parts.

- Endless Diamond Wire Cutting: Wire cutting, uses a thin wire to create precise cuts in alumina. It’s a non-contact method and is ideal for applications requiring high precision, like electrical insulators or small components.

Each of these methods has its advantages and is chosen based on the specific requirements of the alumina machining task. The choice of method depends on factors such as the required precision, material thickness, and the complexity of the shapes needed. Additionally, advances in cutting technologies, such as the use of diamond-coated tools or water jet systems, have significantly improved the efficiency and precision of alumina machining processes.

Challenges of Traditional Cutting Methods:

Owing to the hardness and brittleness of alumina, traditional cutting methods posed several challenges:

- Износ инструмента: Conventional tools were prone to severe wear when cutting alumina, reducing tool durability.

- Thermal Damage: Some traditional cutting methods, such as high-speed cutting, could generate high temperatures during cutting, resulting in material damage.

- Risk of Damage: Due to the brittleness of alumina, traditional cutting methods might cause material breakage, fractures, and waste.

Advantages of Circular Diamond Wire Cutting

In recent years, круглая алмазная проволока cutting technology has gained prominence and offers significant advantages in machining alumina:

- Высокая точность: Circular diamond wire cutting provides excellent cutting precision, enabling the production of complex geometries on alumina machining to meet various application requirements.

- Сокращение отходов: Thanks to its high precision, circular diamond wire cutting minimizes waste and damage to the material.

- Versatile for Multiple Materials: Circular diamond wire cutting is suitable for various materials, including both conductive and non-conductive ones, offering new possibilities for alumina machining and other ceramic materials.

- High Cutting Speed: Circular алмазная резка проволоки operates at higher speeds, enhancing production efficiency.

- Suitable for Different Thicknesses: In contrast to traditional cutting methods, circular diamond wire cutting is applicable to workpieces of various thicknesses, with no significant limitations.

Heat Generation Issue

It should be noted that circular diamond wire cutting does generate some heat, but it is relatively low in comparison to other cutting methods. This is because circular diamond wire cutting employs an extremely fine wire for cutting, and the thinness of the wire facilitates efficient cooling, reducing the risk of thermal damage.

Заключение

The application of circular diamond wire cutting technology in alumina machining offers significant advantages to the manufacturing industry. It delivers high precision, waste reduction, and versatility for multiple materials, making alumina processing more efficient and feasible. This technology’s emergence provides the manufacturing industry with more choices and is expected to further expand the application areas of alumina and other ceramic materials.

The translation should meet or exceed 800 words, making it suitable for publication.