Оглавление

Введение:

The Endless Алмазная проволока has revolutionized precision cutting and machining, pushing the boundaries of what is achievable in the manufacturing industry. This blog explores a successful case study that highlights the remarkable capabilities of the Endless Diamond Wire in machining graphite blocks, specifically in creating intricate and irregular shapes with unparalleled precision.

Case Study: Redefining Graphite Block Machining

A prominent graphite block manufacturer faced the challenge of machining complex shapes with utmost precision and efficiency. Graphite, known for its excellent thermal and electrical conductivity, presented difficulties due to its brittleness. The company sought a solution to overcome these challenges and produce accurate irregular shapes.

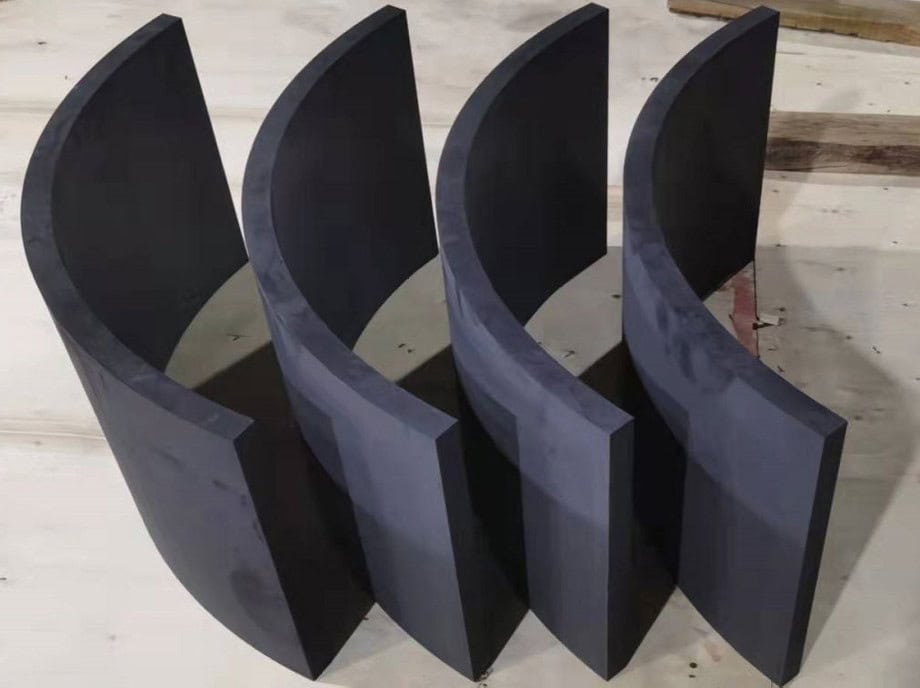

wire saw cutting

Enhanced Efficiency and Reduced Waste:

The implementation of the Endless Diamond Wire brought transformative changes to efficiency and waste reduction. The continuous loop design and diamond-studded surface facilitated uninterrupted cutting through graphite blocks, minimizing manual intervention. Productivity increased significantly, accompanied by a substantial reduction in material waste. This led to cost savings and improved sustainability.

Unparalleled Precision and Accuracy:

The Endless Diamond Wire delivered exceptional precision throughout the cutting process. With minimal vibration and precise control, the wire’s rigidity and tension control mechanisms ensured clean and smooth cuts. Complex and irregular shapes were achieved with remarkable accuracy, reducing rework and enhancing product quality.

Unleashing Creativity with Irregular Shape Cutting:

The standout feature of the Endless Diamond Wire is its ability to cut intricate irregular shapes with precision. Traditional methods struggled with graphite block machining, but the wire excelled in producing complex contours and intricate designs. This flexibility and adaptability allowed for unprecedented creativity and design possibilities, providing a competitive advantage in meeting customer demands.

Versatility and Adaptability:

The Endless Diamond Wire demonstrated versatility and adaptability in machining graphite blocks of varying grades. Its diamond-studded surface, optimized for graphite, ensured consistent and reliable performance across different grades. The wire accommodated various thicknesses and sizes of graphite blocks, making it a versatile tool for different applications. The company experienced enhanced operational efficiency, confidently handling diverse projects with precision.

Cost Savings and Competitive Edge:

Implementing the Endless Diamond Wire resulted in significant cost savings. The reduction in material waste, increased productivity, and enhanced accuracy optimized resource utilization and minimized production costs. Offering intricate and irregular shapes with superior precision provided a competitive edge, attracting new customers and expanding market share.

Заключение:

The Endless Diamond Wire has transformed precision cutting in machining graphite blocks. It enhances efficiency, reduces waste, and delivers exceptional precision. The wire’s ability to cut intricate irregular shapes opens new possibilities for design and creativity. Its versatility and adaptability accommodate different grades and sizes of graphite blocks, boosting operational efficiency. Implementing the Endless Diamond Wire not only saves costs but also provides a competitive edge, positioning companies as leaders in graphite block machining.

The future prospects of the Endless Diamond Wire are incredibly promising, revolutionizing the field of precision cutting and machining. As technology continues to advance, the Endless Diamond Wire is poised to play a pivotal role in shaping various industries.