Keywords: Electrical Discharge Wire Cutting, Endless Diamond Wire

Оглавление

In modern manufacturing, material cutting is a crucial process that significantly impacts the quality and performance of the final product. Two widely used high-precision cutting techniques are Electrical Discharge Wire Cutting (EDM Wire Cutting) and Endless Diamond Wire Cutting. This article delves into the differences and similarities between these two cutting methods, shedding light on their respective applications and strengths.

Electrical Discharge Wire Cutting: Precision Spark Erosion Cutting

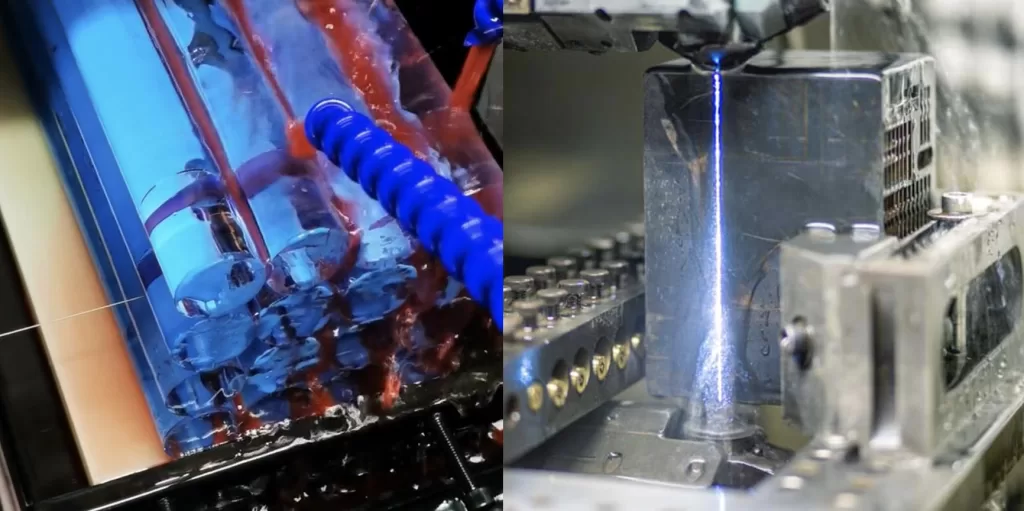

Let’s begin by understanding Electrical Discharge Wire Cutting, a cutting technology based on the principle of electrical spark erosion. It employs a thin wire as an electrode, using electrical sparks between the wire and the workpiece to remove material. EDM Wire Cutting excels in the manufacturing of intricate parts and molds, thanks to its ability to achieve highly precise cuts, whether in metals or other conductive materials.

Key Features and Advantages of EDM Wire Cutting:

- Высокая точность: EDM Wire Cutting can achieve precision at the micrometer level, making it an ideal choice for manufacturing precision components.

- Complex Shapes: Due to its non-mechanical cutting nature, EDM Wire Cutting can effortlessly handle complex part geometries.

- Low Stress: Compared to traditional mechanical cutting, EDM Wire Cutting imposes minimal stress on the workpiece, reducing the risk of deformation.

Limitations of EDM Wire Cutting:

- Conductivity Requirement: EDM Wire Cutting relies on the conductivity of the workpiece, making it unsuitable for cutting non-conductive materials like ceramics and glass.

- Отделка поверхности: While EDM Wire Cutting can achieve high precision, it may result in a rougher surface finish compared to other cutting methods, requiring additional post-processing.

Endless Diamond Wire Cutting: Innovative High-Efficiency Cutting

Now, let’s turn our attention to Бесконечная алмазная резка проволоки, a relatively new cutting technology that uses a wire embedded with diamond particles to cut various materials, whether they are conductive or non-conductive. This innovative technique has found wide-ranging applications in industries such as semiconductor manufacturing, solar cell production, and optical glass processing.

Ключевые особенности и преимущества бесконечной алмазной резки проволоки:

- Multi-Material Cutting: Endless Diamond Wire Cutting can be used to cut a wide range of materials, including both conductive and non-conductive ones, giving it versatility across industries.

- Высокая эффективность: Endless Diamond Wire Cutting typically boasts higher cutting speeds compared to traditional methods, enhancing production efficiency.

- Точность: The cutting accuracy of diamond wire is exceptionally high, ensuring the manufacture of high-quality components.

Comparing Electrical Discharge Wire Cutting and Endless Diamond Wire Cutting:

- Пригодность материала: Electrical Discharge Wire Cutting is primarily suitable for conductive materials, while Endless Diamond Wire Cutting can cut almost any material, regardless of its conductivity.

- Скорость резки: Endless Diamond Wire Cutting often has a higher cutting speed, which is crucial for bulk production.

- Точность: When it comes to precision, Electrical Discharge Wire Cutting still holds an advantage, especially for manufacturing complex parts.

Заключение

Electrical Discharge Wire Cutting and Endless Diamond Wire Cutting are two cutting technologies that play pivotal roles in modern manufacturing. They offer distinct advantages and limitations in cutting conductive and non-conductive materials. Manufacturers typically choose the appropriate cutting method based on their specific requirements. Regardless of the method chosen, both techniques ensure high-quality cutting results, addressing various manufacturing challenges.