-(Wire Cutting Machine) with Integrated Swinging Function

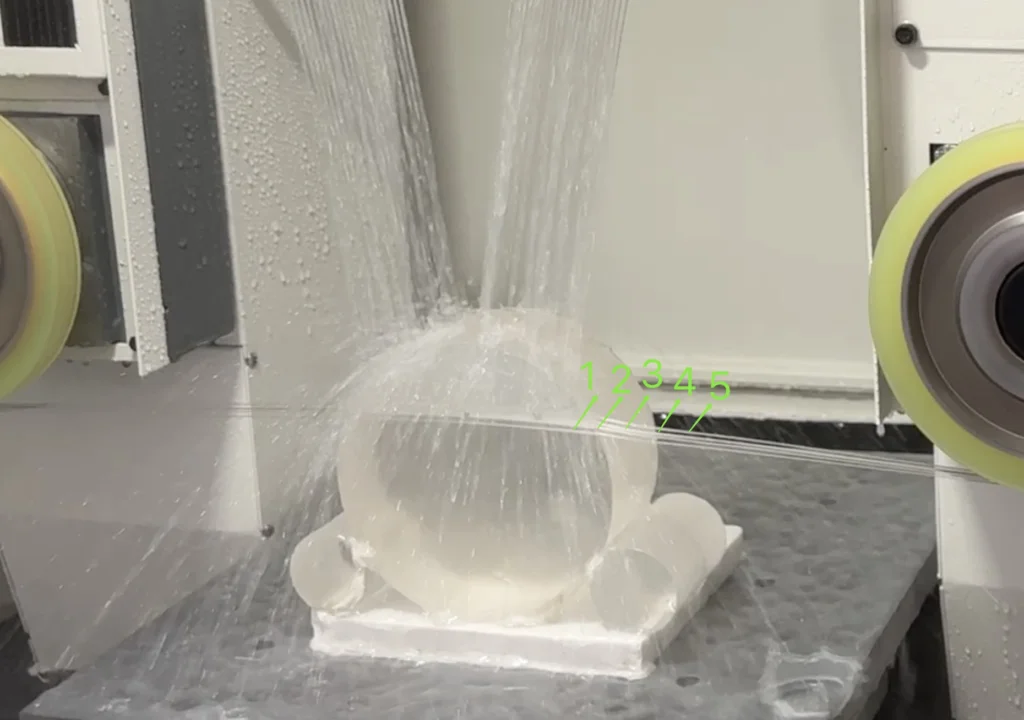

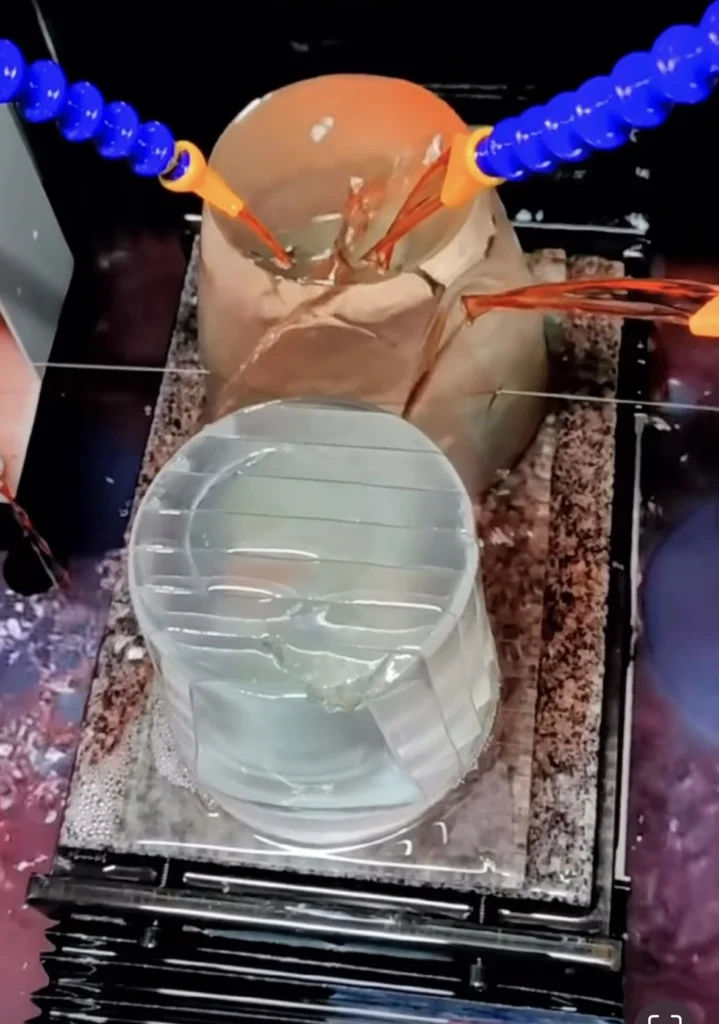

The highlight of this Swinging Wire Cutting Machine is the addition of the cutting wire’s oscillation function and multi-wire cutting. By addressing the challenges encountered in cutting superhard materials, we have enhanced the swinging amplitude of the guide wheels in the circular wire cutting equipment. This enables faster cutting of materials such as sapphire and quartz, resulting in smoother surfaces. Additionally, we have overcome tensioning issues, allowing for simultaneous cutting with 5 circular wires, thereby increasing cutting efficiency.

Click on the text above to quickly jump to the corresponding section.

Swinging Wire Cutting Machine Client On-site Video

Unique advantages of the Swinging function

1,Исключительная резкость:

Adding a swing motion when cutting hard materials can enhance the sharpness of the cutting wire, resulting in faster cutting speeds. Normally the cut speed of quartz is 7 mm/min but with aswing function, the cut speed can be rised to 10 to 12 mm/min.

2,Превосходное качество поверхности:

The cutting surface of the diamond wire is usually very smooth. Adding a swinging motion to the cutting wire is equivalent to grinding during cutting, resulting in an even better cutting surface finish.

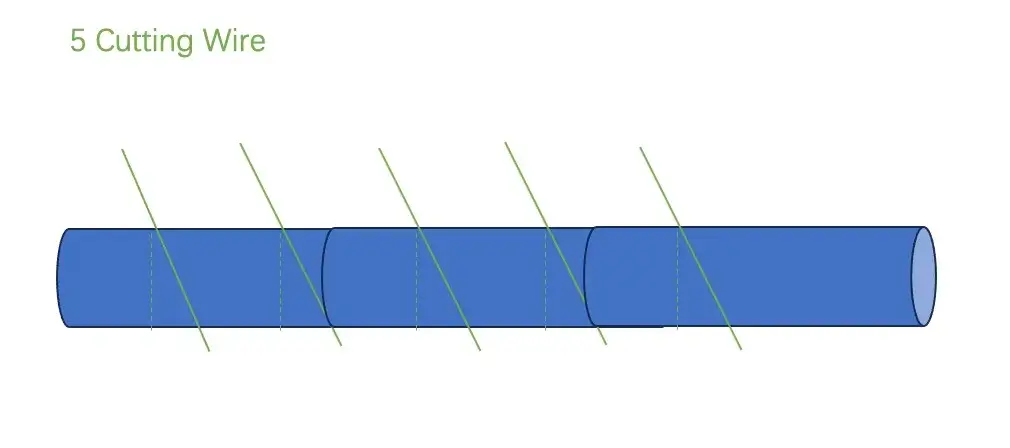

4,Cutting with 5 wires simultaneously.

The equipment’s guide wheel simultaneously carries 5 loop diamond wires, enabling cutting of 6 pieces of material at once, significantly enhancing production efficiency.

Свяжитесь с нами

Swinging Wire Cutting Machine Details

Принцип работы этой пилы для резки графитовой проволоки

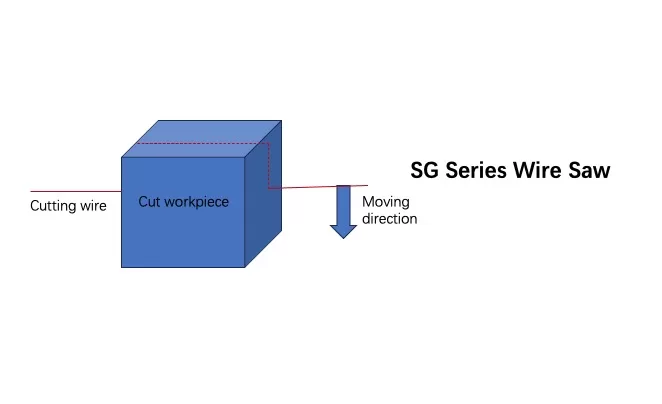

1,Gantry-style Cutting

Drawing of Gantry-style Cutting

2, Контроль и точность:

Оборудование обеспечивает исключительно высокую точность резки - от 0,05 мм до 0,1 мм в зависимости от размера заготовки.

The swing degree can be set from the system.

Parameter of this Swinging Wire Cutting Machine:

| Нет. | Имя | Технические характеристики |

| 1 | Максимальная длина заготовки (мм) | 400 |

| 2 | Максимальная ширина заготовки (мм) | 400 |

| 3 | Максимальная высота заготовки (мм) | 375 |

| 4 | Перемещение рабочего стола по оси Y (мм) | 400 |

| 5 | Перемещение рабочего стола по оси Z (мм) | 400 |

| 6 | Максимальная скорость алмазной проволоки (м/с) | 38 |

| 7 | Минимальный прирост подачи по оси Y (мм) | 0.01 |

| 8 | Минимальное увеличение подачи по оси Z (мм) | 0.01 |

| 9 | Повтор Точность позиционирования по оси Y (мм) | 0.03 |

| 10 | Повтор Точность позиционирования по оси Z (мм) | 0.03 |

| 11 | Общая потребляемая мощность (кВт) | 4 |

| 12 | Источник питания | 220V 50Hz |

| 13 | Размер машины (мм) | 1200*950*2000 |

| 14 | Вес машины (кг) | 600 |

| 15 | Swing Degree | set on request |

Other Models with Same Structure

there are machines of different size and additional function similar to this Swinging Wire Cutting Machine type.

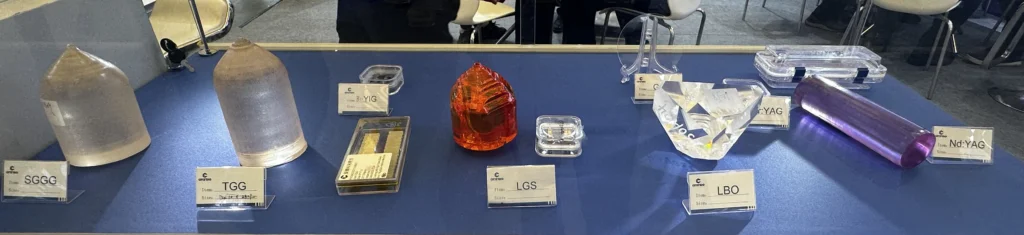

Successful Applications of this SGTS 40

Поддержка и услуги

Техническое и сервисное обслуживание:

We provide comprehensive maintenance and servicing services to ensure the long-term reliable operation of the Swinging Wire Cutting Machine. Our dedicated maintenance team possesses extensive experience and technical knowledge to promptly respond to and resolve equipment issues. We made check list to conduct regular preventive maintenance, inspecting and adjusting critical components to ensure optimal performance and accuracy. Whether it’s routine maintenance or emergency repairs, we are committed to delivering fast and efficient servicing to minimize equipment downtime.

Обучение:

We offer comprehensive training programs designed to empower customers with in-depth knowledge and proficiency in operating and maintaining . Our training courses cover basic equipment operation, safe usage practices, maintenance procedures, and troubleshooting. Customized training content and flexible training methods, including on-site training, remote training, and provision of training materials, are provided based on customer needs and backgrounds. Through our training programs, customers can enhance their operational skills, improve equipment efficiency, and ensure long-term reliable performance.

Консалтинг:

Мы предоставляем профессиональные консультационные услуги to meet customer needs for this Swinging Wire Cutting Machine. Our team of experts offers tailored advice and solutions based on specific requirements. Whether it’s equipment selection, process optimization, production line layout, or quality control, we collaborate with customers, providing professional guidance and technical support. We strive to establish long-term partnerships with customers, working together to address various technical and engineering challenges, meet their needs, and achieve mutual success.

Идеальное решение проблем с резкой

Вертикальный станок для резки проволоки может быть адаптирован к любой сцене резки с удовлетворительной производительностью

Мы принимаем образец резки службы, оставить вашу информацию и наслаждаться нашей бесплатной резки тест службы →.

-1536x1024.jpg)

-1-1536x886.jpg)

.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1-1536x861.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1536x1024.jpg)