CNC contour cutting machines are changing the way many industries work, from manufacturing to layout. These machines offer excessive accuracy and performance, saving time and money. But what exactly are automated cutting machines? CNC stands for Computer Numerical Control. These machines are managed by computers to reduce substances into precise shapes. Whether running with foam, plastic, or metal, a CNC contour-cutting machine can handle everything.

This article will explore the essential blessings of using CNC contour-cutting machines. We’ll explain how they paint and why they’re a fantastic device for many industries.

Benefits of Using a CNC Contour Cutting Machine

High Precision and Accuracy

One of the biggest blessings of CNC contour cutting machines is their precision. Because the machines are PC-managed, they can make very correct cuts. This is specifically important for groups that want exact shapes or measurements.

For instance, if you’re making elements for a plane or car, even the slightest mistake can cause considerable trouble. CNC foam cutter can reduce materials to fractions of a millimeter, ensuring that every element fits flawlessly. This type of accuracy might be challenging to achieve with manual cutting gear.

Saves Time and Boosts Efficiency

Time is money inside the global company, and CNC contour cutting machines help save a lot of time. Because the machines are computerized, they can cut large quantities of cloth quickly and effectively, much faster than cutting substances by hand.

Moreover, the machines can work constantly without getting tired or making mistakes to grow standard productiveness.

Versatile in Material Cutting

CNC contour cutting machines can work with many unique substances. These machines can reduce foam, wood, plastic, steel, or composite substances. This makes them very flexible, mainly in industries wherein a ramification of materials is used.

For example, if your corporation involves designing packaging foam or growing prototypes, computerized cutting technology can accommodate all of your desires. You don’t need separate gear for every fabric.

Reduces Waste and Material Costs

Another high-quality benefit of CNC contour cutting machines is that they help reduce waste. Since the machines are so accurate, they use the most effective fabric for every pastime. This way, there is much less waste, ultimately saving you coins on materials.

For instance, in case you’re slicing foam to make cushions, прецизионные режущие инструменты will lessen each piece flawlessly, so you’re no longer losing any extra foam. This isn’t the most effective in your rate range, but it is also effective for the environment because it reduces cloth waste.

Easy to Use and Repeatable

Even though CNC contour slicing machines use advanced generation, they will be spotless. Once you’ve programmed the gadget with the proper commands, it may lessen the equal format repeatedly without any modifications. This makes CNC machines ideal for mass manufacturing, in which you want many identical elements.

Improves Safety inside the Workplace

Using CNC contour cutting machines can also make your place of work more secure. Since the machines are automated, workers don’t want to manage risky slicing devices, reducing the chance of damage.

For instance, in industries where sharp blades are used to cut foam, steel, or wood, injuries are always a hazard. Contour cutting equipment copes with this cutting technique without putting people in harm’s way.

Cost-Effective in the Long Run

At first, CNC contour cutting machines can also appear pricey. However, they’re a price-powerful investment in the end. The gadget’s accuracy and overall performance lessen the need for redesign, saving time and money. Additionally, the bargain in material waste and stepped forward productivity assist in cutting general costs.

Where Can I Buy a CNC Contour Cutting Machine?

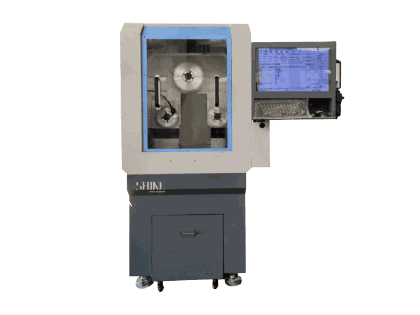

If you are looking to shop for a CNC contour-cutting tool, selecting a reliable supplier is crucial. One of the super providers within the agency is Блеск. They are recognized for imparting outstanding Industrial CNC machines that deliver precision, overall performance, and sturdiness. Shine is recognized for its pinnacle-notch customer service and assistance. Whether you’re new to high-speed CNC cutter or skilled, Shine can guide you through finding the proper tool for your desires. Their considerable choice makes it easy to find a gadget that suits your corporation, regardless of the scale or challenge type.

What Is the Best CNC Contour Cutting Machine?

When it entails selecting the brilliant CNC contour slicing machine, the SGI 20 regularly is the top choice. The SGI 20 is ideal for its accuracy and overall performance. It can manipulate a spread of substances, encompassing foam, timber, and plastic, making it flexible for unique industries. The SGI 20 additionally offers excessive-tempo cutting, which helps corporations keep time and increase productiveness. Plus, it is smooth to use, even if you’re no longer an expert. With its precision and reliability, the SGI 20 is an excellent choice for corporations looking to enhance their cutting processes.

Frequently Asked Questions (FAQs)

What varieties of materials can CNC contour cutting machines manage?

CNC contour cutting machines can cut a wide range of materials, including foam, plastic, timber, steel, and composites. Their versatility makes them suitable for many unique industries.

Are CNC contour cutting machines challenging to use?

No, they may be no longer hard to apply. Once programmed, the machines can run mechanically, making them function smoothly. Training is often supplied to ensure clients are acquainted with the software program and tool operations.

Final Words

CNC contour slicing machines provide many benefits that can assist businesses in beautifying their production methods. They provide extreme precision, store time, and reduce cloth waste, making them excellent for industries that require unique and correct cutting. Additionally, their versatility in dealing with various materials, ease of use, and ability to improve workplace safety make them a super investment.