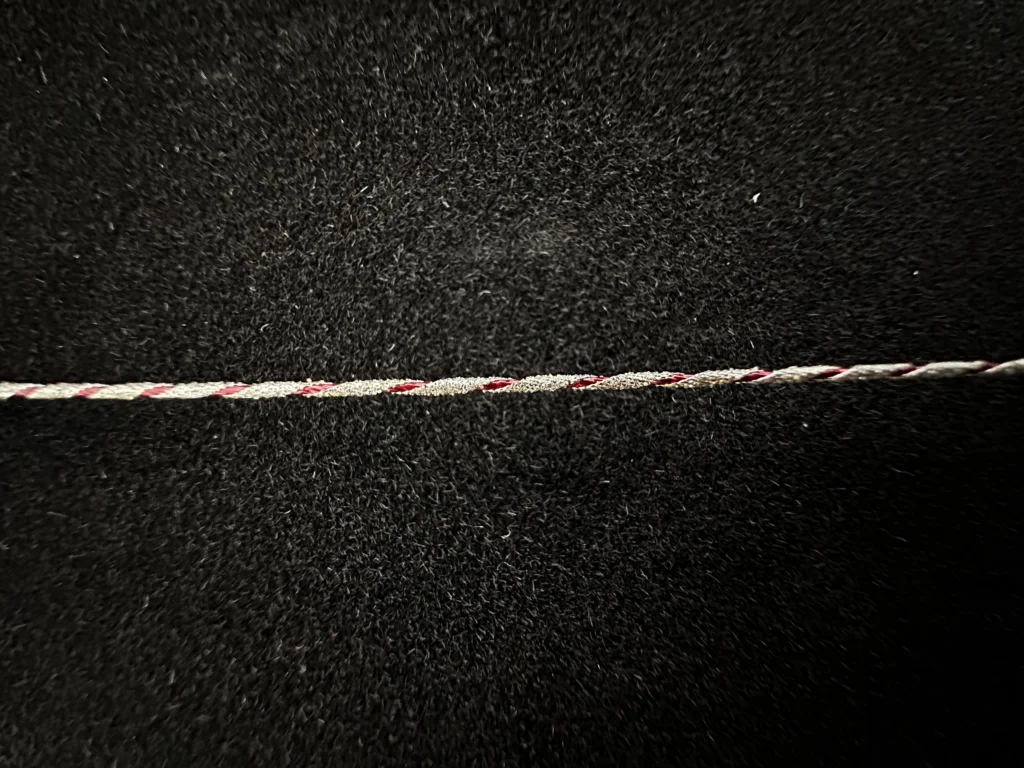

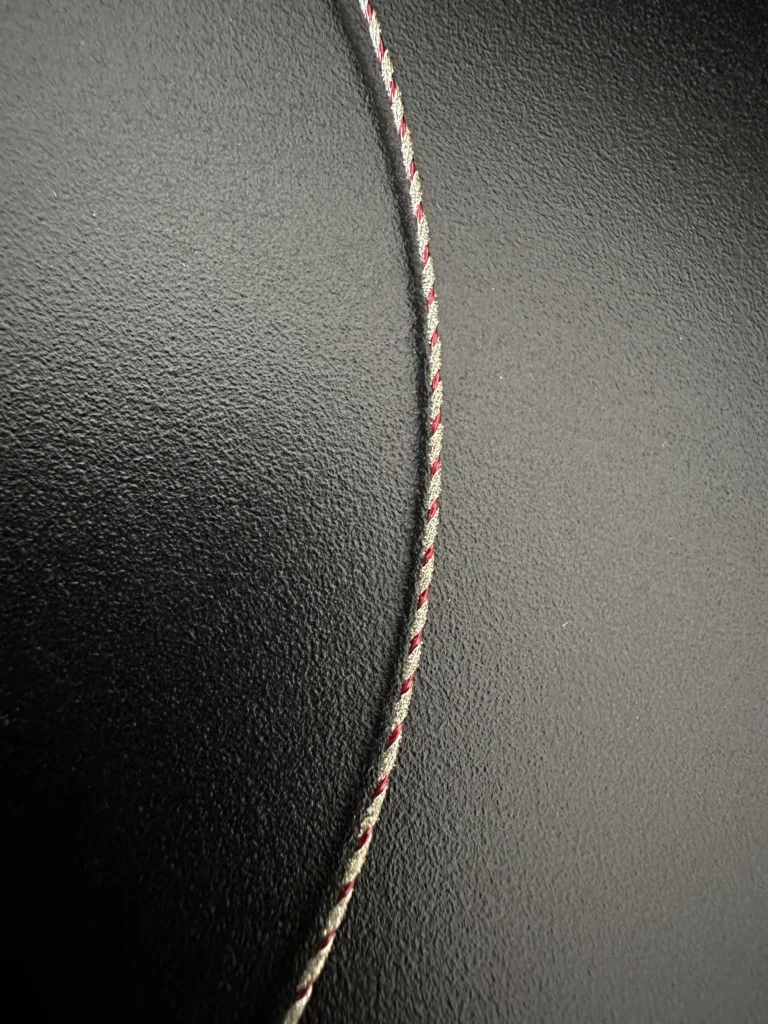

Петля из алмазной проволоки с нитяным покрытием

The threaded-coated diamond wire loop was developed successfully at the end of 23, representing a novel type of circular diamond wire. Its coating exhibits a threaded pattern, which facilitates the discharge of debris during the cutting process, thereby significantly extending the lifespan of the cutting wire.

Петля из алмазной проволоки с нитяным покрытием

Click on the text above to quickly jump to the corresponding section.

Technical Spec Parameter

| Outer Dia (mm) | Coating Method | Провод для сердечника (мм) | Working Force (N) | Breaking Force (N) | Wire Length (M) |

| 0.55 | Thread | 0.33 | 100 | 200 | 1-4 |

| 0.65 | Thread | 0.39 | 135 | 270 | 1-4 |

| 0.8 | Thread | 0.51 | 210 | 440 | 1-10 |

| 1.0 | Thread | 0.6 | 250 | 500 | 1-10 |

Note:

- The working tension is generally half of the breaking tension, but as long as it does not exceed, it can be used.

- If the length of the wire is not within the recommended length, please communicate with us.

- Various materials can be cut as long as their hardness is lower than that of diamonds.

Advantages of Thread Coated Diamond Wire Loop

- Debris removal is faster.

Conventional diamond wire loops are fully coated with diamond particles on the surface. When cutting materials with relatively low hardness but prone to generating a large amount of debris, the cutting force is often not the primary requirement. The inability to smoothly expel a large amount of debris results in the encapsulation of diamond particles on the cutting wire, wasting cutting force.

Резьбовое покрытие создает на поверхности алмазной проволоки спиральные зазоры, в которые при вращении режущей проволоки может попадать большое количество обломков материала. При движении режущей проволоки она переносит и сбрасывает обломки, значительно повышая производительность удаления стружки.

- Longer Serving Life

The rapid discharge of debris ensures that the surface of the diamond wire remains free from debris accumulation, keeping it sharper and more effectively utilized. As a result, the threaded coating diamond wire can have a lifespan 2 to 3 times longer compared to traditional fully coated wires.

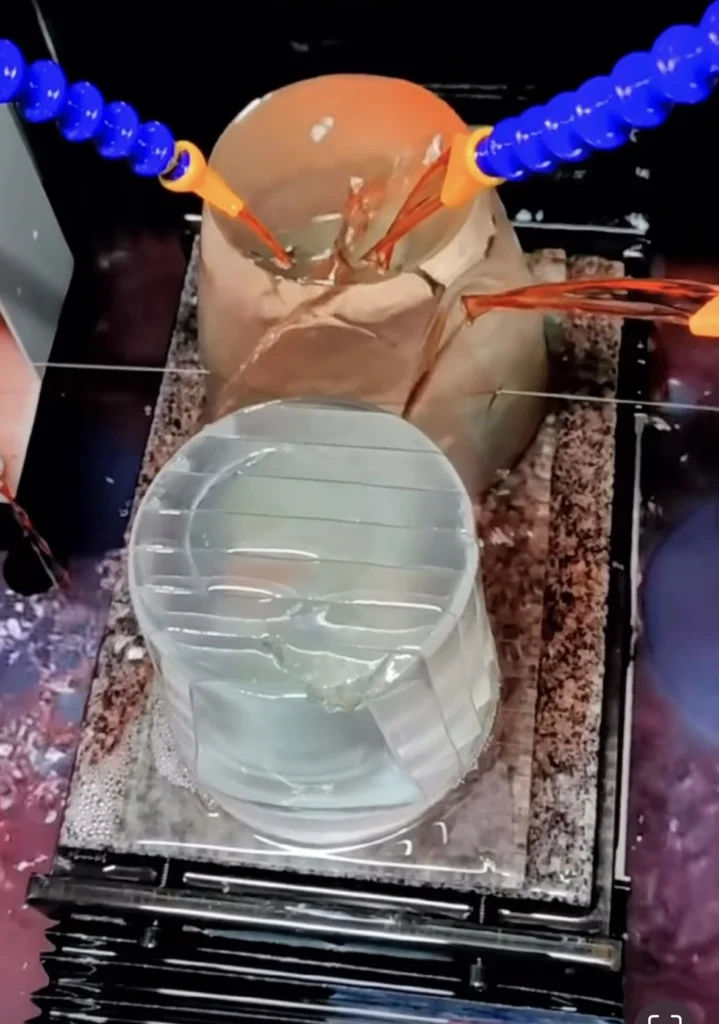

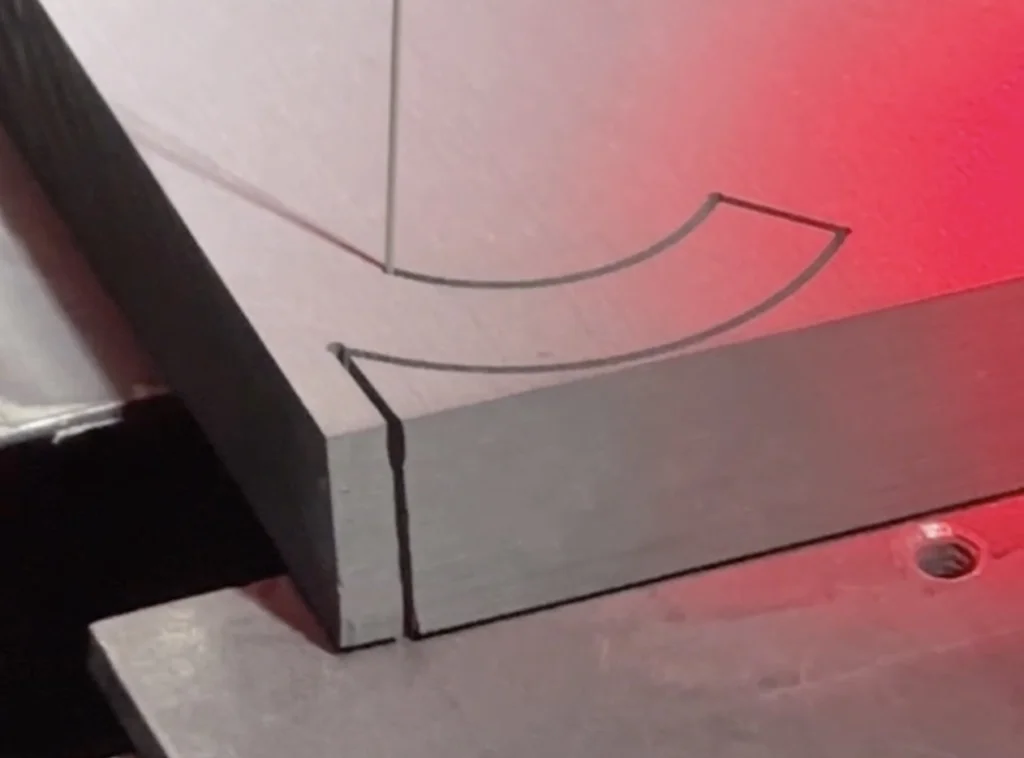

Applications of Thread Coated Diamond Wire Loop

And More Applications!

Q&A about Thread Coated Diamond Wire Loop

- What materials can I cut with the thread coated diamond wire Loop ?

You can cut a variety of hard materials with the diamond wire including glass, ceramic, stone and graphite…

You can cut material which need to keep it’s structure ,such as honeycomb material,Fossils,cultural relics and so on.

Anyway it can cut anything softer than diamond ,and extremelly suitable to cut expensive ones.

- what is the difference between thread coated diamond wire loop and traditonal ones?

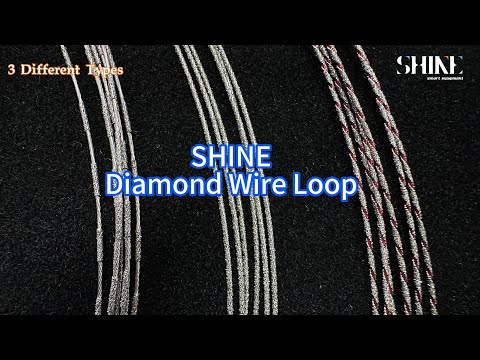

the video show 3 different type of петля из алмазной проволокиs.

- How long will a endless diamond wire loop last?

The lifespan of a endless diamond wire loop will vary depending on the material you are cutting and the thickness of the wire. However, most diamond wires will last for several days of use.

- What are the environmental benefits of using an endless diamond wire saw?

Endless diamond wire loops are a more environmentally friendly because it’s wire dia is quite small, so the cutting kerf is small too. By this way the material Debris removal will be Substantially reduced.