Introduction

In the world of industrial cutting, precision, efficiency, and innovation are paramount. Wire cutting technology, a key player in this domain, has revolutionized how materials are cut, shaped, and processed. This article delves deep into the world of wire sawing technology, highlighting its significance, diverse applications, and the groundbreaking development of the endless diamond wirecutting method.

Оглавление

Understanding Wire Cut Technology

At its core, wirecutting technology involves using a thin wire as a cutting tool to slice through various materials. This wire, often made of metal or infused with abrasive particles, moves through the material to make precise cuts. The technology encompasses several types, including Electrical Discharge Machining (EDM) and abrasive wirecutting, each suitable for different materials and precision requirements.

The Evolution of wire sawing Technology

Wire cutting technology has evolved significantly since its inception. From basic mechanical cutting to advanced EDM and abrasive methods, this evolution reflects the industry’s drive towards greater accuracy and efficiency. The introduction of computer numerical control (CNC) in wirecutting machines further propelled this technology, allowing for complex and precise cuts with minimal waste.

Applications of wire sawing Technology

The versatility of wirecut technology makes it invaluable across various industries. In the aerospace sector, it’s used for cutting intricate components, while in the automotive industry, it shapes parts with precision. In electronics, wire sawing is essential for creating detailed circuit boards and components. The technology is also used in the medical field for manufacturing surgical tools and implants.

Advantages of Wire cutting Technology

The primary advantages of wirecut technology are its precision and ability to handle complex shapes. Unlike traditional cutting methods, wire sawing produces smoother surfaces and more accurate cuts, reducing the need for secondary processing. Its efficiency in terms of time and material usage makes it a cost-effective solution for many industrial applications.

Endless Diamond Wire cutting : A Game-Changer

A significant advancement in wirecut technology is the development of the endless diamond wirecut method. This innovative approach uses a wire embedded with diamond particles, offering unparalleled cutting capabilities. The “endless” aspect refers to the continuous, unsegmented loop of wire, which allows for faster, more efficient cutting with less wire breakage and maintenance.

Key Features of Endless Diamond Wire cutting

- Enhanced Precision and Speed: The diamond-infused wire cuts through the hardest materials with ease, maintaining high precision.

- Reduced Material Waste: The thinness and accuracy of the diamond wire result in minimal material loss, crucial for expensive or rare materials.

- Improved Efficiency: With less downtime for wire changes and maintenance, the endless diamond wirecut method significantly improves overall efficiency.

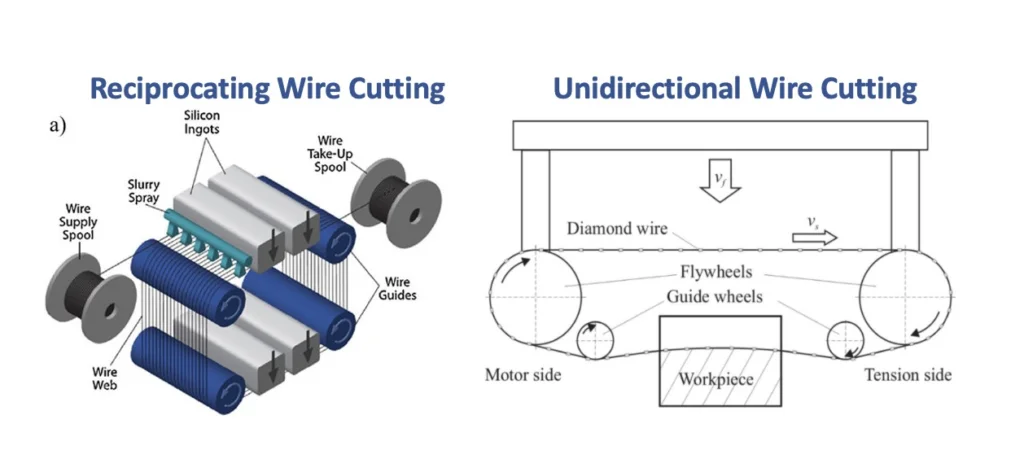

Comparing wire sawing Methods

While traditional wirecut methods remain effective for many applications, the endless diamond wirecut method stands out for its advanced capabilities, especially when dealing with extremely hard materials like silicon, sapphire, and certain metals. This comparison highlights the suitability of different wirecut methods for various industrial needs.

Challenges and Solutions in Wire Cut Technology

Despite its many advantages, wirecut technology faces challenges, such as wire breakage, maintenance, and the need for specialized skill sets for operation. Addressing these challenges, advancements like the endless diamond wirecut method have been developed, offering more robust, reliable, and user-friendly solutions.

Future Trends in Wire Cut Technology

Looking ahead, wirecut technology is poised for further innovation. Integration of AI and automation could lead to smarter, more precise cutting machines. Advancements in wire materials, like the development of more durable and efficient wires, are expected to enhance cutting capabilities and reduce operational costs.

Selecting the Right Wire Cut Method for Your Needs

Choosing the appropriate wirecut technology depends on several factors, including material type, desired precision, and production volume. For industries requiring cutting of very hard materials or high-precision components, the endless diamond wirecut method is an optimal choice. Understanding specific needs and industry trends is crucial in making an informed decision.

Maintenance and Safety in Wire Cut Operations

Proper maintenance is key to the longevity and optimal performance of wirecut machines. Regular checks, timely repairs, and adhering to safety protocols ensure smooth operation and prevent workplace accidents. Operators should be trained in both the technical aspects of the machines and the safety procedures.

Заключение

Wirecut technology, particularly with the introduction of the endless diamond wirecut method, represents a significant leap forward in industrial cutting. It offers a blend of precision, efficiency, and versatility, making it a preferred choice in various industries. As technological advancements continue to unfold, wirecut technology is expected to become even more integral to industrial processes, pushing the boundaries of what’s possible in material cutting and shaping.