Keywords: Wire Cutting Techniques, Precision Machining, EDM Wire Cutting, Endless Diamond Wire Cutting, Metal Wire Cutting, Wire Drilling, High-Speed Wire Cutting, Waterjet Wire Cutting, Thermal Wire Cutting.

Оглавление

Введение

In the realm of manufacturing, material cutting is a critical process that determines the quality and performance of the final product. Wire cutting techniques, known for their high precision, find extensive applications in various industries, ranging from electronics manufacturing to aerospace. This article delves into the intricacies of different wire cutting techniques and their modern industrial applications.

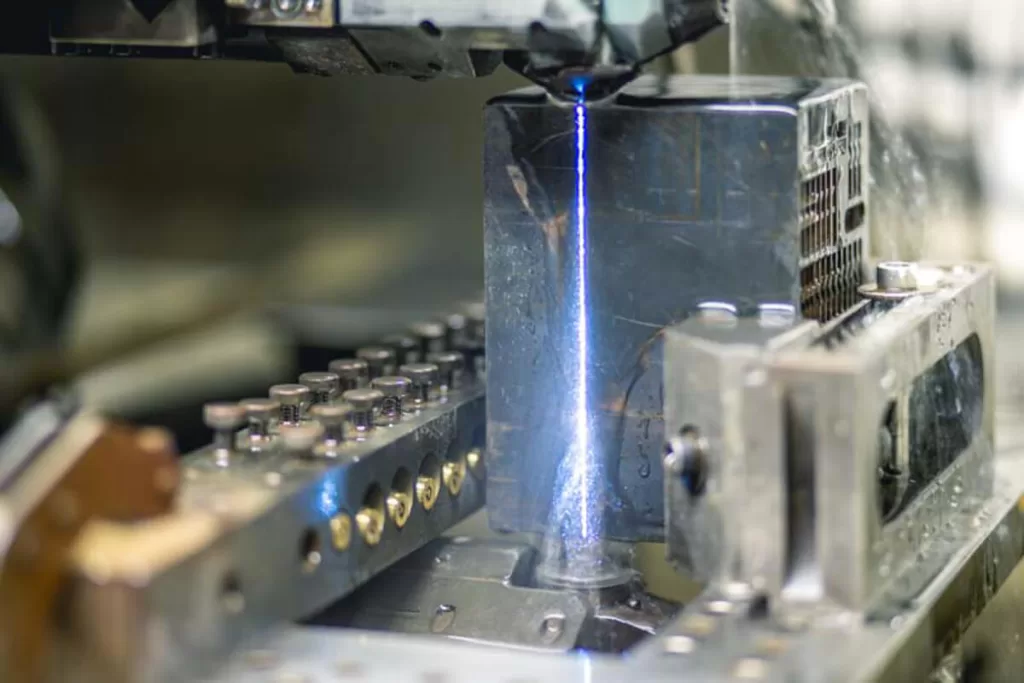

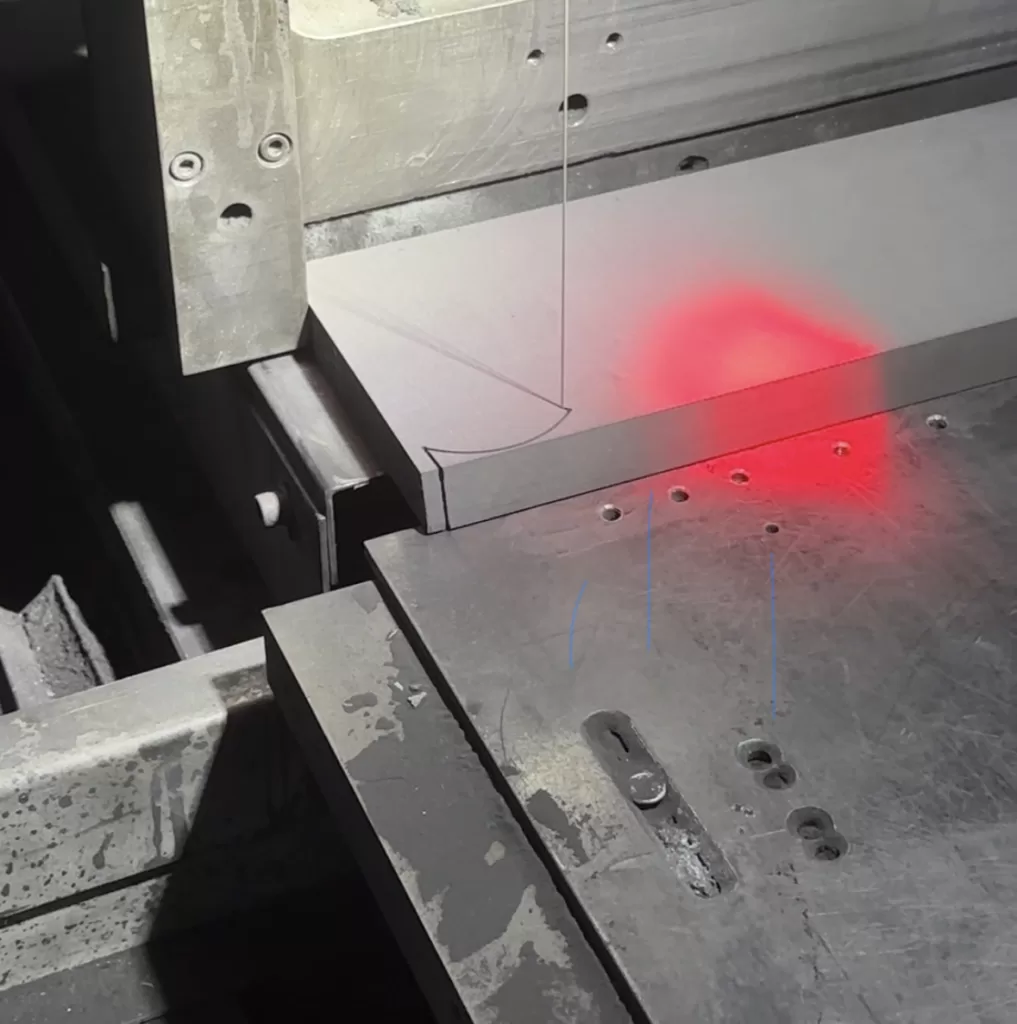

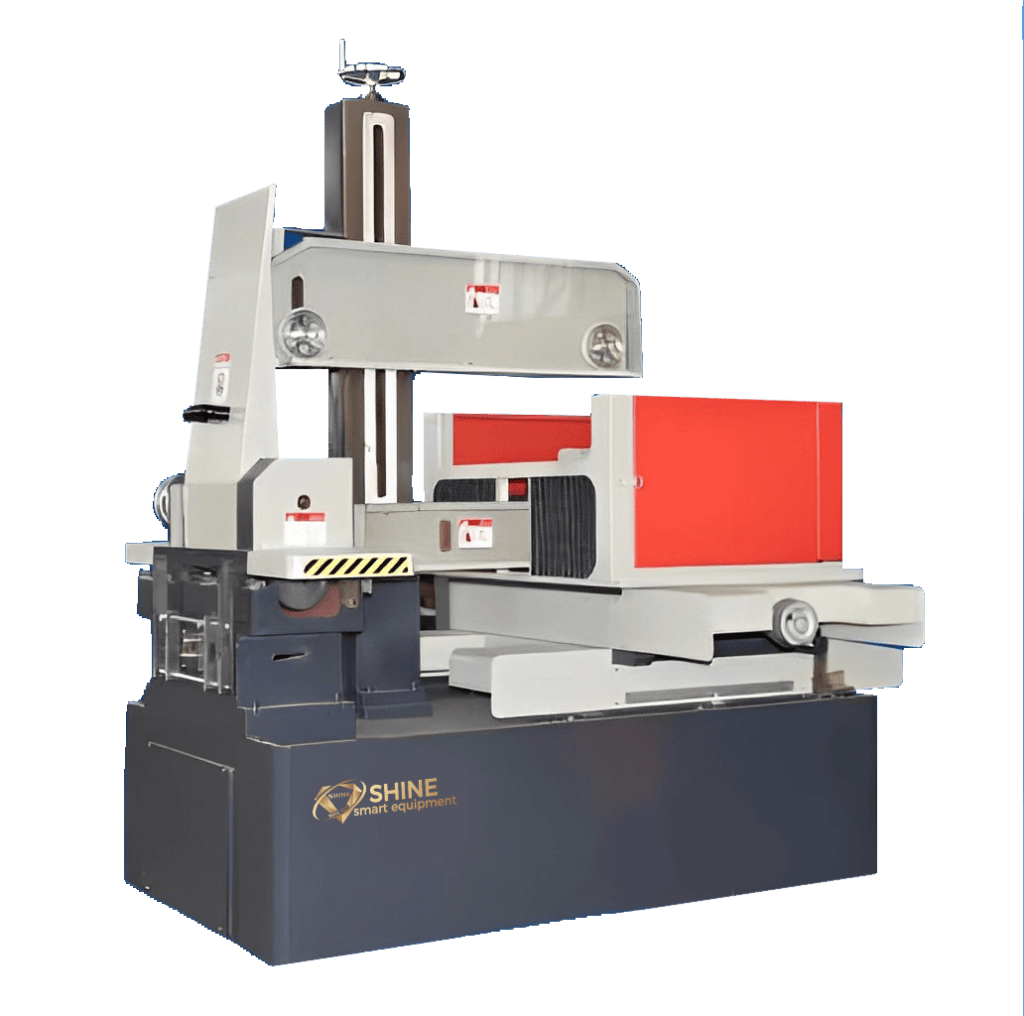

1. EDM Wire Cutting Techniques(Electric Discharge Wire Cutting)

Electric discharge machining (EDM) is a highly precise method that employs a fine wire electrode to methodically remove material from the workpiece via electrical discharge or spark erosion. This technique is renowned for its ability to create intricate and highly precise cuts, making it a go-to choice in the manufacturing of complex components like molds, tools, and gears.

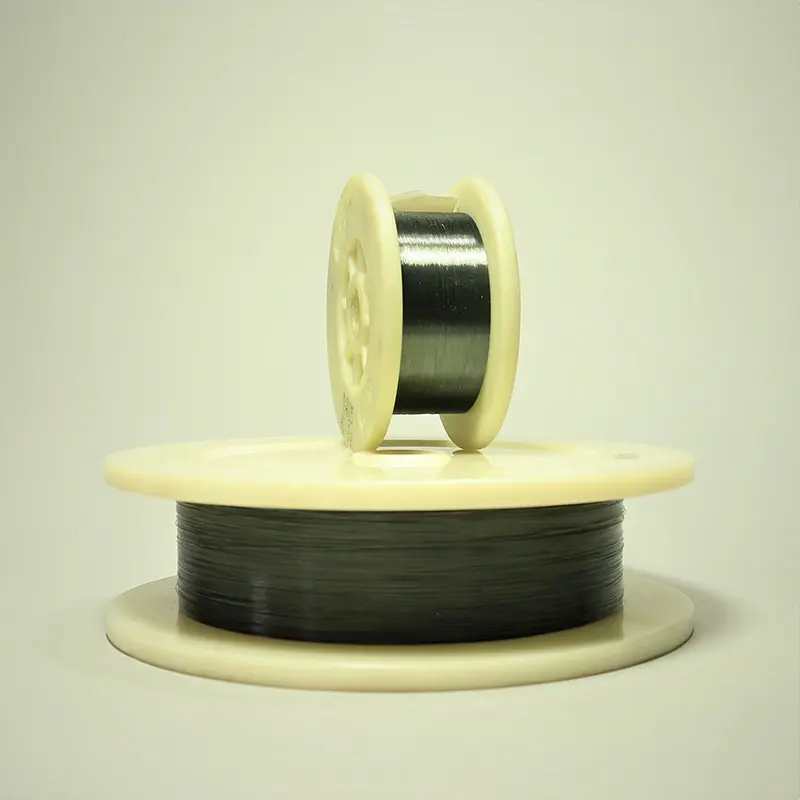

2. Endless Diamond Wire Cutting

Endless diamond wire cutting represents an emerging high-precision cutting method that utilizes a wire embedded with diamond particles to cut a wide range of materials. This innovative technology has garnered widespread acclaim across various industries, including semiconductor manufacturing, solar cell production, and optical glass processing. In comparison to traditional cutting methods, endless diamond wire cutting boasts significantly higher cutting speeds and enhanced cutting quality. Furthermore, it offers the distinct advantage of not imposing strict limitations on material size, thereby substantially improving overall cutting efficiency.

3. Metal Wire Cutting

Metal wire cutting leverages metal wire, frequently made of steel, as its cutting medium. This technique enjoys extensive usage in the realm of metalworking industries, where it serves as the primary method for cutting steel plates, pipes, and structural components. The significance of metal wire cutting in key manufacturing sectors like construction, automotive, and various engineering projects cannot be overstated.

4. Wire Drilling

Wire drilling represents a specialized wire cutting technique primarily utilized for creating holes or perforations in workpieces. This method proves indispensable in the manufacturing of molds, precision drilling, and cutting special materials, offering meticulous control over hole diameter and depth.

5. High-Speed Wire Cutting

High-speed wire cutting harnesses the power of a vibrating wire with high-speed oscillations for cutting purposes, resulting in heightened precision and efficiency. This technique truly excels in high-volume cutting environments, such as metal manufacturing and mold production, where efficiency is of paramount importance.

6. Waterjet Wire Cutting

Waterjet wire cutting marries high-pressure water jets with wire cutting techniques, resulting in a versatile cutting method applicable to various materials, including metals, stones, and glass. This approach guarantees a clean, precise, and cold cutting process.

7. Thermal Wire Cutting

Thermal wire cutting banks on an electrically heated wire or filament for material cutting, frequently finding application in the cutting of foam, insulation materials, plastics, and other similar materials. This technique proves particularly valuable in applications demanding rapid, precise, and clean cuts.

Заключение

In modern manufacturing, wire cutting techniques play a pivotal role, offering solutions for a wide array of applications, from crafting intricate components to cutting complex shapes. As technology continues its relentless advance, wire cutting methods will undeniably spearhead progress in manufacturing, delivering efficient, precise, and innovative cutting solutions across various domains. Whether it’s EDM wire cutting, endless diamond wire cutting, or any other wire cutting methodology, their collective contributions are instrumental in shaping the contemporary industrial landscape. These techniques collectively embody the essence of precision and efficiency that defines modern manufacturing processes.