Ключевые слова: Проволочная пила для драгоценных камней, оборудование для резки

Знакомство с проволочной пилой для драгоценных камней

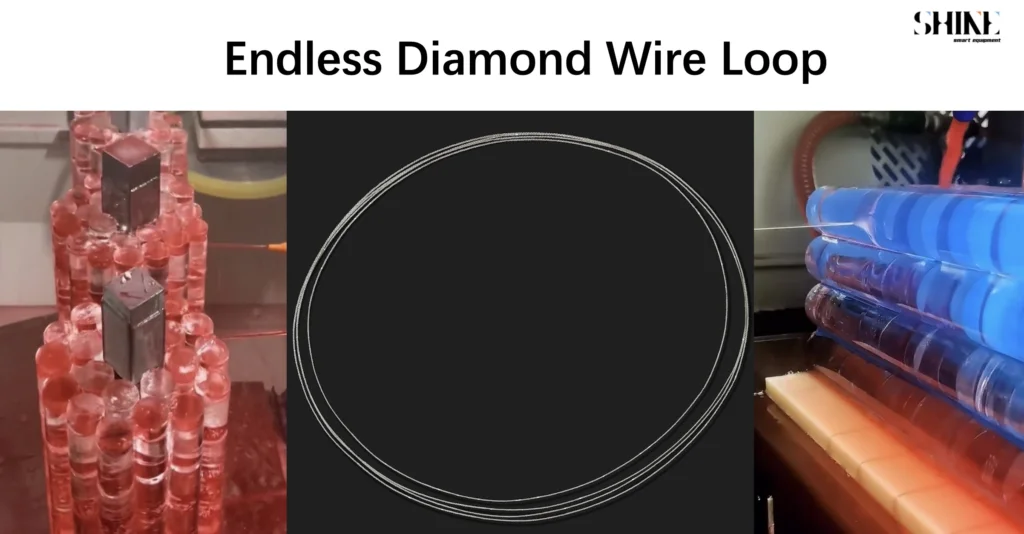

Петлевая алмазная проволочная пила представляет собой значительное достижение в технологии точной резки, особенно в области обработки драгоценных камней. Как профессиональный инженер, понимание механики и применения "проволочной пилы для драгоценных камней" имеет решающее значение. Эта статья посвящена техническим особенностям петлевых алмазных проволочных пил с акцентом на их применение в огранке драгоценных камней - области, где точность и аккуратность имеют первостепенное значение.

Наука, лежащая в основе алмазных проволочных пил

Петлевые алмазные пилы - это передовые инструменты как в прямом, так и в переносном смысле. Они состоят из петлеобразной проволоки с частицами алмаза, самого твердого из существующих материалов, что делает их идеальными для резки таких прочных материалов, как драгоценные камни. Основное преимущество использования "проволочной пилы для драгоценных камней" заключается в ее точности и способности делать сложные разрезы, не повреждая драгоценный материал.

Роль петлевых алмазных пил в распиловке проволоки для драгоценных камней

В мире огранки драгоценных камней точность и деликатность, предлагаемые пилами с алмазной проволокой, не имеют себе равных. Эти пилы обеспечивают точную огранку драгоценных камней, сводя к минимуму количество отходов и повышая качество конечного продукта. The "Проволочная пила для драгоценных камней" особенно ценится за способность создавать сложные формы и дизайны, которые пользуются большим спросом на рынке драгоценных камней.

Петлевая алмазная проволочная пила для обработки драгоценных камней

Технология производства алмазных проволочных пил постоянно развивается, и постоянные инновации повышают их пригодность в качестве "проволочной пилы для драгоценных камней". Среди последних достижений - разработка более тонких и прочных проволок с алмазным напылением и усовершенствованных систем контроля натяжения. Эти инновации обеспечивают более чистый рез и больший контроль, что крайне важно для деликатного процесса огранки драгоценных камней.

Одним из наиболее значительных достижений в технологии "проволочной пилы для драгоценных камней" является интеграция систем автоматизированного проектирования (CAD) и автоматизированного производства (CAM). Эти системы обеспечивают точный контроль над процессом резки, позволяя создавать сложные узоры и рисунки на драгоценных камнях, которые ранее было невозможно или непомерно дорого производить.

Тематические исследования: Петлевые алмазные проволочные пилы в обработке драгоценных камней

Реальные примеры применения алмазных проволочных пил для резки драгоценных камней демонстрируют их эффективность и точность. Например, в одном известном случае "проволочная пила для драгоценных камней" была использована для разрезания крупного редкого драгоценного камня на несколько частей без какого-либо повреждения его тонкой внутренней структуры. При использовании традиционных методов резки эта задача была бы крайне рискованной, а то и вовсе невозможной.

Другой пример - производство драгоценных камней по индивидуальному заказу для ювелирных изделий высокого класса. В этом случае точность "Проволочной пилы для драгоценных камней" позволила создать сложные формы и конструкции, удовлетворяющие особым требованиям клиентов и добавляющие значительную ценность конечному продукту.

Проблемы и решения при резке драгоценных камней проволочными пилами

Несмотря на свои передовые возможности, использование пил с петлевой алмазной проволокой для резки драгоценных камней сопряжено с определенными трудностями. Одной из таких проблем является риск возникновения внутренних напряжений в драгоценном камне в процессе резки. Однако "проволочная пила для драгоценных камней" решает эту проблему благодаря мягкому режущему воздействию и точному контролю, что значительно снижает вероятность возникновения таких напряжений.

Еще одной проблемой является работа с различными видами драгоценных камней, каждый из которых обладает уникальными свойствами. Универсальность "Проволочной пилы для драгоценных камней" позволяет настраивать и калибровать ее для разных типов драгоценных камней, обеспечивая оптимальные условия резки для каждого материала.

Тенденции будущего и заключение

В будущем "проволочная пила для драгоценных камней" станет еще более точной и эффективной благодаря развитию технологий и материалов. Такие инновации, как искусственный интеллект и машинное обучение, могут произвести дальнейшую революцию в огранке драгоценных камней, позволяя выполнять еще более сложную и детальную работу.

В заключение следует отметить, что пила с алмазной проволокой стала незаменимым инструментом в индустрии огранки драгоценных камней. Благодаря своей точности, эффективности и адаптивности она идеально подходит для тонкой и сложной работы по огранке драгоценных камней. По мере развития технологий "проволочная пила для драгоценных камней" будет продолжать играть ключевую роль в этом искусном и точном ремесле.