Are you tired of struggling with outdated wire cutting methods that slow down your production processes? Do you find yourself facing challenges when using wire cutting machines? If so, you’re not alone. Many businesses struggle to harness the full potential of wire cut wire technology. In this guide, we delve into the world of wire cutting machines, exploring their benefits, challenges, and best practices. Join us as we uncover the secrets to maximizing the efficiency and effectiveness of wire cutting operations.

Оглавление

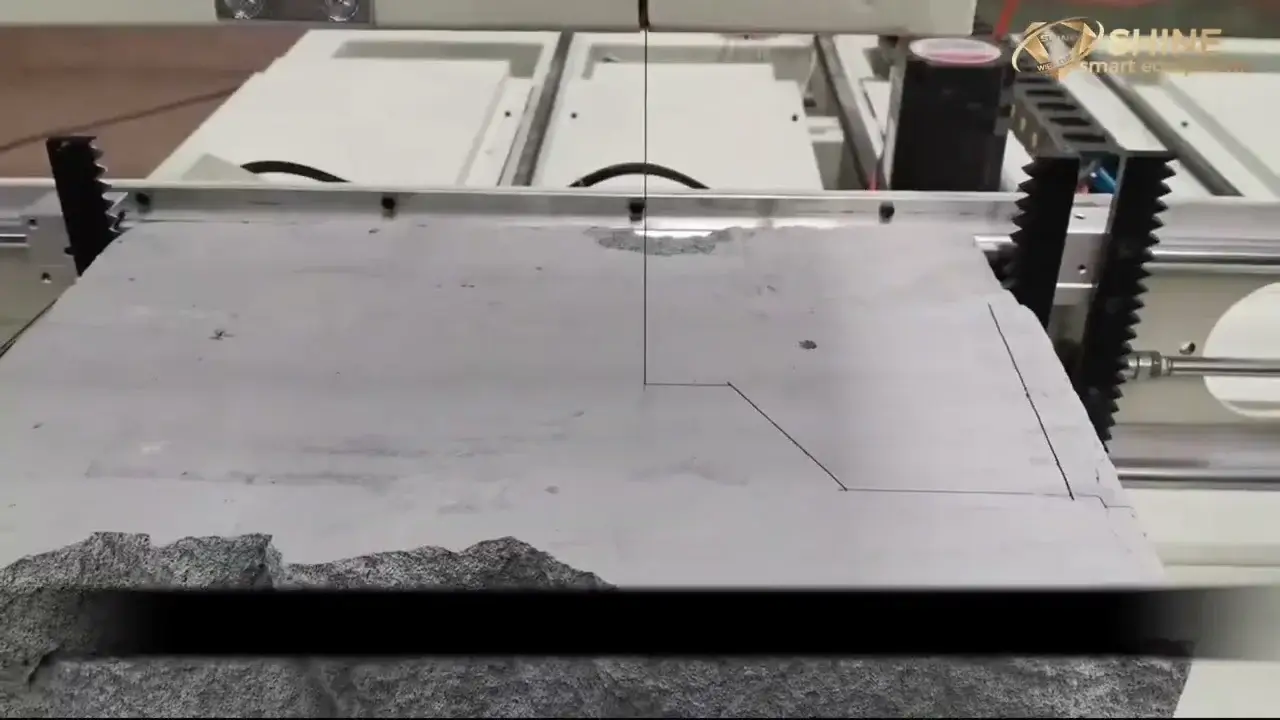

Wire cutting machines have transformed industries across the globe, offering precision cutting solutions for a wide range of applications. From automotive manufacturing to construction and beyond, wire cutting machines play a crucial role in modern production processes. However, harnessing the full potential of these machines requires knowledge, skill, and expertise. In the following sections, we’ll explore the ins and outs of wire cutting technology, providing you with valuable insights and practical tips to elevate your wire cutting operations to new heights.

| Maintenance Aspect | Daily Maintenance | Еженедельное обслуживание | Monthly Maintenance |

|---|---|---|---|

| Смазка | Apply lubricant to moving parts such as the wire drum and guide rollers. | Check and replenish lubricant levels as needed. | Clean and inspect lubrication system components for any signs of wear or damage. Replace or repair as necessary. |

| Wire Tension | Check wire tension and adjust as needed to ensure optimal cutting performance. | Perform a thorough inspection of wire tension system components. | Calibrate wire tensioning system and verify proper functioning. |

| Wire Inspection | Inspect wire for signs of wear, damage, or fatigue. Replace worn or damaged wire segments. | Conduct a visual inspection of the entire wire length. | Remove and replace worn wire segments as needed. |

| Machine Alignment | Check machine alignment using precision tools. Make adjustments as necessary. | Perform a detailed alignment check on all machine components. | Conduct laser alignment procedures to ensure precise cutting accuracy. |

| Coolant System | Monitor coolant levels and top up as needed. Clean coolant filters and screens. | Flush and refill coolant reservoir. Clean coolant lines and filters. | Inspect coolant pump and hoses for leaks or damage. Replace worn components. |

| Electrical Components | Inspect electrical connections and wiring for signs of wear or corrosion. | Tighten loose connections and clean electrical terminals. | Conduct electrical system testing and diagnostics. Replace faulty components. |

Как обслуживать станок для резки алмазной проволоки

Станки для резки алмазной проволоки are essential tools in various industries, including construction, mining, and manufacturing. These machines use diamond-coated wires to cut through hard materials such as concrete, stone, and metal with precision and efficiency. To ensure consistent performance and prolong the lifespan of your diamond wire cutting machine, proper maintenance is crucial. In this comprehensive guide, we’ll explore the essential steps to maintain your equipment and keep it operating at its best.

Понятие о станке для алмазной резки проволоки

Before diving into maintenance procedures, it’s essential to understand how your diamond wire cutting machine works. These machines consist of several components, including the wire, drive system, tensioning mechanism, and cutting head. Each component plays a vital role in the cutting process, and proper maintenance of these parts is necessary for optimal performance.

- Components Overview: Explore the various components that make up your SHINE diamond wire cutting machine, including the wire, blade, tensioning system, and control panel.

- Working Mechanism: Gain insight into how your SHINE machine operates, from the initial setup to the cutting process, and understand its efficiency and precision.

- Требования к обслуживанию: Learn about the routine maintenance tasks required to keep your SHINE diamond wire cutting machine in optimal condition, ensuring smooth operation and prolonged lifespan.

- Safety Measures: Discover the safety features and protocols integrated into your SHINE machine to protect operators and prevent accidents during operation.

- Performance Optimization: Explore techniques and best practices for maximizing the performance and efficiency of your SHINE diamond wire cutting machine, achieving superior cutting results.

- Troubleshooting Tips: Access a comprehensive guide to troubleshooting common issues that may arise with your SHINE machine, along with step-by-step solutions for quick resolution.

- Training Resources: Explore training resources and materials provided by SHINE to equip operators with the knowledge and skills required to operate the machine effectively and safely.

Регулярный осмотр и очистка

One of the most critical aspects of maintaining your diamond wire cutting machine is regular inspection and cleaning. Before each use, visually inspect the machine for any signs of wear, damage, or loose components. Check the wire tension and alignment to ensure smooth operation during cutting tasks. Additionally, clean the machine after each use to remove debris, dust, and other contaminants that may affect performance.

Смазка и консистентная смазка

Proper lubrication is essential to reduce friction and wear on moving parts of the diamond wire cutting machine. Regularly lubricate the drive system, tensioning mechanism, and cutting head according to the manufacturer’s recommendations. Use high-quality lubricants and greases suitable for the specific components of your machine to ensure smooth operation and prevent premature wear.

Регулировка натяжения

Maintaining proper tension in the diamond wire is crucial for achieving precise cuts and preventing wire breakage. Periodically check the tension of the wire and adjust it as needed using the tensioning mechanism. Over-tensioning or under-tensioning the wire can lead to cutting inaccuracies and damage to the machine. Follow the manufacturer’s guidelines for tension adjustment to ensure optimal performance.

Замена лезвия

The diamond wire blade is a consumable component of the cutting machine and requires regular replacement to maintain cutting efficiency. Monitor the condition of the wire blade during use and replace it when signs of wear or damage are detected. Always use high-quality replacement blades recommended by the manufacturer to ensure consistent cutting performance and safety.

Меры предосторожности

When performing maintenance tasks on your diamond wire cutting machine, always prioritize safety. Follow proper lockout/tagout procedures to prevent accidental startup of the machine during maintenance. Wear appropriate personal protective equipment, including gloves, safety glasses, and hearing protection, to reduce the risk of injury. Additionally, familiarize yourself with the machine’s operation manual and safety guidelines before performing any maintenance tasks.

1. Operator Training and Certification

- Ensure all operators undergo comprehensive training sessions conducted by SHINE experts.

- Emphasize the importance of understanding machine controls, emergency procedures, and safety protocols.

2. Personal Protective Equipment (PPE)

- Mandate the use of appropriate PPE, including safety goggles, gloves, ear protection, and steel-toed boots.

- SHINE-branded safety gear ensures optimal protection and compliance with industry standards.

3. Machine Inspection Before Operation

- Conduct a thorough inspection of the SHINE diamond wire cutting machine before each use.

- Check for loose components, damaged wires, or any signs of wear and tear that could compromise safety.

4. Secure Work Area

- Establish designated work zones with clear signage to prevent unauthorized access.

- Ensure the work area is free from clutter and obstructions to facilitate safe operation of the machine.

5. Emergency Stop Procedures

- Familiarize operators with the location and function of the emergency stop button on the SHINE machine.

- Practice emergency stop procedures to halt the machine immediately in case of an accident or malfunction.

6. Wire Tensioning and Maintenance

- Regularly inspect and adjust wire tension according to SHINE’s recommended guidelines.

- Avoid over-tensioning or under-tensioning the wire, as it can lead to equipment damage or safety hazards.

7. Safe Handling of Materials

- Educate operators on the proper handling and loading of materials onto the cutting bed.

- Use lifting equipment or machinery to move heavy materials safely and avoid manual lifting.

8. Fire Safety Measures

- Keep fire extinguishers readily accessible in the vicinity of the SHINE diamond wire cutting machine.

- Conduct regular fire drills and provide training on how to respond to potential fire hazards effectively.

9. Regular Maintenance and Servicing

- Schedule routine maintenance checks and servicing of the SHINE machine to ensure optimal performance and safety.

- Follow SHINE’s maintenance schedule and recommendations for lubrication, cleaning, and part replacement.

10. Compliance with Regulations

- Stay updated on industry regulations and standards related to diamond wire cutting machine operation and safety.

- Ensure full compliance with local, regional, and international safety regulations to mitigate risks and liabilities.

Watch our informative video guide on wire cutting machines to learn everything you need to know about this cutting-edge technology. From tips and tricks to expert insights, we’ve got you covered. Click the link to watch now!

Mastering Wire Cutting Machines: A Comprehensive Guide

Заключение

Proper maintenance is essential for maximizing the performance and longevity of your diamond wire cutting machine. By following the tips outlined in this guide, you can ensure that your equipment operates smoothly and efficiently, delivering precise cuts for your projects. Remember to inspect, clean, lubricate, and adjust your machine regularly to keep it in top condition. By investing time and effort in maintenance, you’ll reap the benefits of consistent performance and reliable operation from your diamond wire cutting machine.

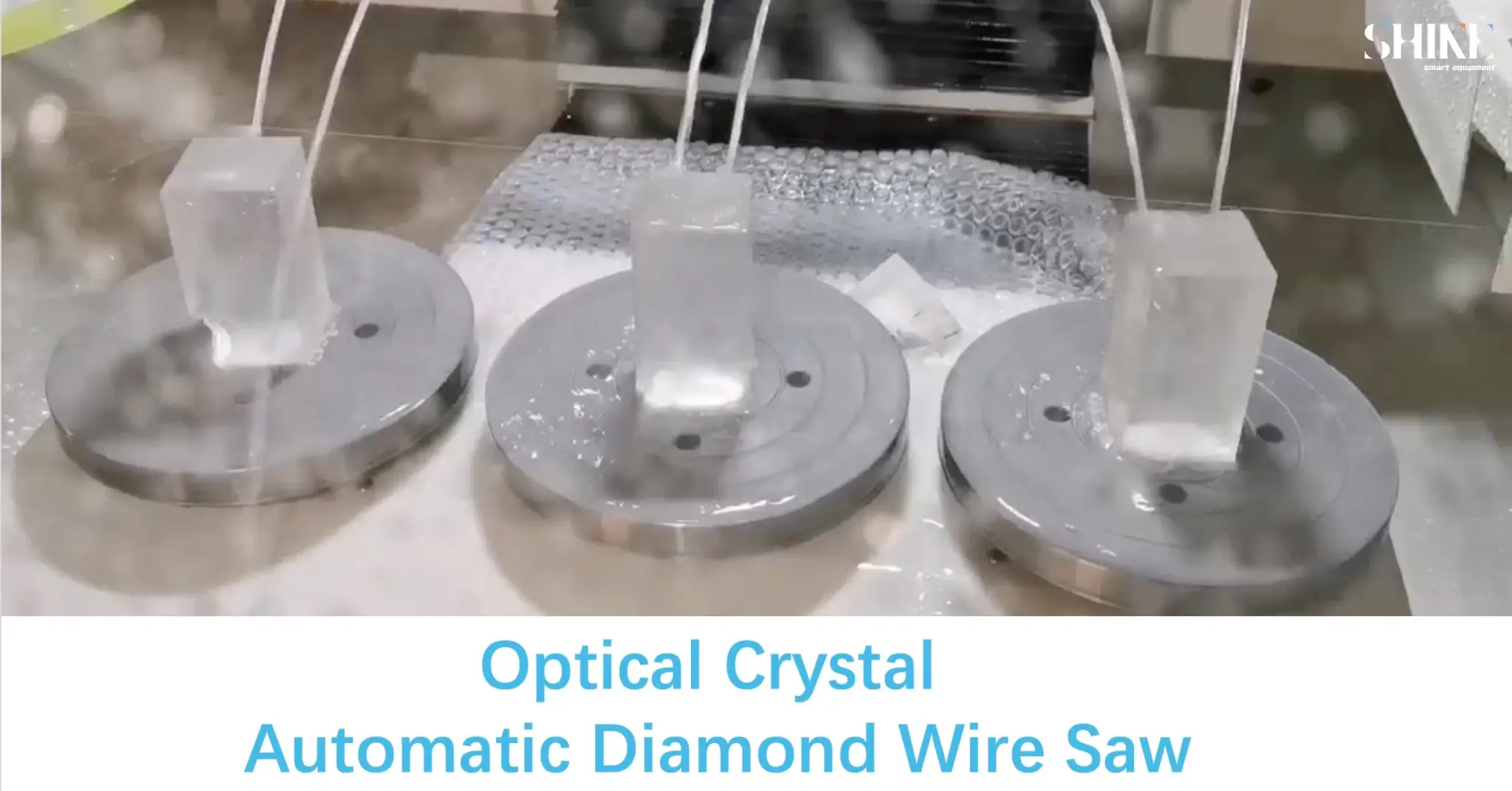

Elevate your cutting processes with SHINE’s state-of-the-art quartz cutting machinery. Designed for precision and efficiency, our cutting-edge machines will revolutionize your production workflows. Click here to explore our range and place your order today!

Upgrade Your Cutting Game with SHINE Оборудование для резки кварца

Incorporate these maintenance practices into your routine to keep your diamond wire cutting machine in optimal condition and extend its lifespan. By prioritizing maintenance, you’ll enjoy reliable performance and consistent cutting results for years to come.

FAQ (часто задаваемые вопросы)

- What is a diamond wire cutting machine? A diamond wire cutting machine is a specialized tool used for cutting various materials, including stone, metal, and concrete. It utilizes a high-strength wire embedded with diamond particles to achieve precise and efficient cuts.

- How does a diamond wire cutting machine work? Diamond wire cutting machines operate by spinning a thin wire coated with diamond particles at high speeds. As the wire makes contact with the material to be cut, the diamond particles grind away at the surface, resulting in clean and precise cuts.

- What materials can be cut using a diamond wire cutting machine? Diamond wire cutting machines are versatile tools capable of cutting a wide range of materials, including granite, marble, steel, and glass. They are commonly used in industries such as construction, mining, and manufacturing.

- What are the advantages of using a diamond wire cutting machine? Some of the key advantages of diamond wire cutting machines include their ability to produce precise cuts with minimal waste, their versatility in cutting various materials, and their efficiency in high-volume cutting operations.

- How do I choose the right diamond wire cutting machine for my needs? When selecting a diamond wire cutting machine, consider factors such as the type of material you’ll be cutting, the desired cutting speed and precision, and your budget. Additionally, look for machines from reputable brands like SHINE to ensure quality and reliability.

- Are diamond wire cutting machines safe to use? When used properly and according to manufacturer guidelines, diamond wire cutting machines are safe tools. However, it’s essential to receive proper training and follow safety precautions to prevent accidents and injuries.