Table of Contents

Introduction

In the ever-evolving world of semiconductor manufacturing, precision and efficiency are paramount. Cutting-edge technologies require cutting-edge tools, and one such tool that has revolutionized the industry is the endless diamond wire. This article delves into the essential role that endless diamond wire plays in semiconductor manufacturing, shedding light on its significance for businesses seeking excellence in this field.

The Semiconductor Industry’s Evolution:

The semiconductor industry has been on a relentless journey of innovation and miniaturization. With the demand for smaller and more powerful electronic devices growing exponentially, manufacturers are constantly searching for ways to enhance their production processes. Among the many advancements, the integration of endless diamond wire cutting technology stands out as a game-changer.

Endless Diamond Wire – An Overview:

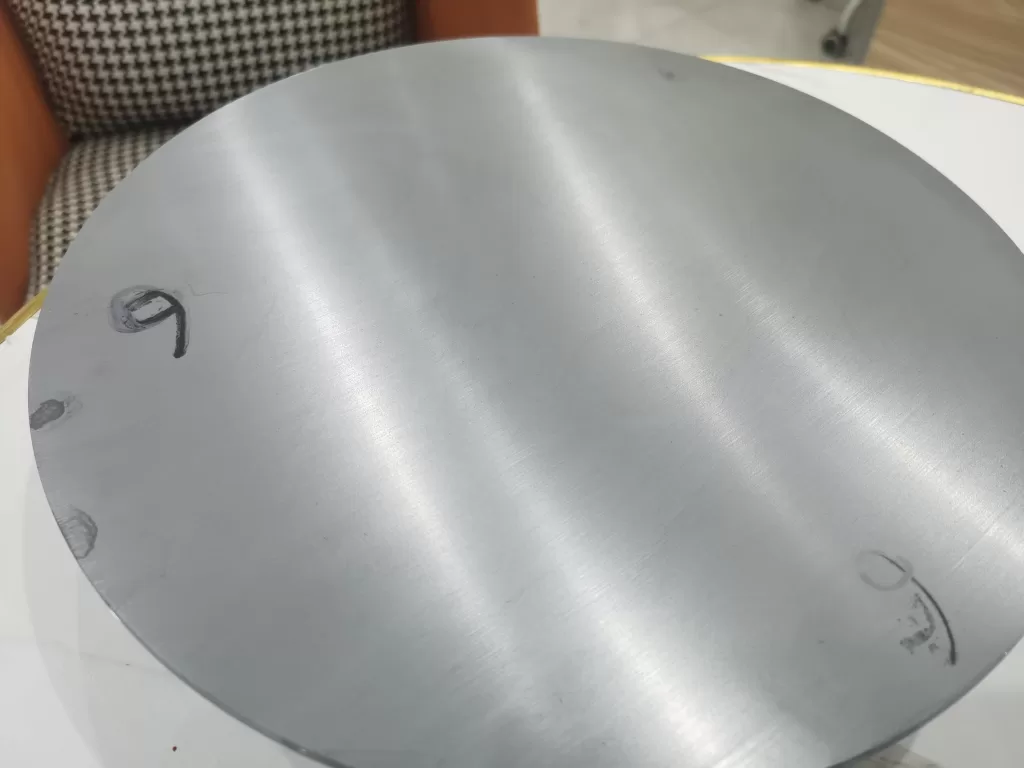

Endless diamond wire is a cutting-edge technology that employs a continuous loop of ultra-thin diamond-coated wire to precisely slice through semiconductor materials. Unlike traditional methods such as dicing saws, which generate more waste and have limitations in terms of cutting accuracy, endless diamond wire offers several key advantages:

1. Exceptional Precision:

The razor-thin diamond wire allows for precise cutting with minimal material loss, resulting in higher yields and reduced production costs.

2.Minimal Contamination:

Endless diamond wire minimizes contamination during the cutting process, ensuring the integrity of the semiconductor materials.

3.Increased Productivity:

The continuous loop design of the wire enables uninterrupted cutting, reducing downtime and increasing overall production efficiency.

4.Versatility:

Endless diamond wire can be used with a wide range of semiconductor materials, including silicon, gallium arsenide, and sapphire, making it a versatile choice for manufacturers.

The Role of Endless Diamond Wire in Semiconductor Manufacturing:

1. Wafer Singulation:

One of the primary applications of endless diamond wire is in the singulation of wafers. It precisely cuts large semiconductor wafers into individual chips, ensuring each chip’s uniformity and quality.

2. LED Production:

In the LED industry, endless diamond wire is instrumental in slicing sapphire substrates, enabling the fabrication of high-quality LED chips.

3. Solar Cell Manufacturing:

Solar cells, which require delicate cutting of silicon wafers, benefit from the precision and efficiency of endless diamond wire technology.

4. MEMS (Micro-Electro-Mechanical Systems):

MEMS devices demand intricate structures, and endless diamond wire provides the precision needed for their fabrication.

5. 3D Integration:

As 3D integration becomes more prevalent in semiconductor manufacturing, endless diamond wire cutting plays a crucial role in creating intricate vertical interconnections.

How Endless Diamond Wire Benefits Your Business:

For businesses involved in semiconductor manufacturing, investing in endless diamond wire technology offers several advantages:

1. Improved Product Quality:

The precision of endless diamond wire translates to higher-quality semiconductor components, enhancing your reputation and customer satisfaction.

2. Cost Efficiency:

Reduced material waste and increased productivity lead to lower production costs and improved profit margins.

3. Competitive Edge:

Staying at the forefront of technology with endless diamond wire cutting machines gives your business a competitive edge in the semiconductor industry.

4. Environmental Responsibility:

Minimized waste and energy-efficient cutting processes align with sustainability goals and environmental responsibility.

Conclusion:

In the dynamic realm of semiconductor manufacturing, the role of endless diamond wire cannot be overstated. Its exceptional precision, minimal waste, and versatility make it a cornerstone technology for businesses seeking excellence in this field. By embracing endless diamond wire cutting machines, your company can deliver higher-quality semiconductor products, optimize production processes, and ultimately gain a competitive advantage in the market. Explore our range of endless diamond wire cutting solutions to take your semiconductor manufacturing to the next level. Your success is our commitment.