Table of Contents

Introduction-Silicon Rod Cutting

In the ever-evolving landscape of semiconductor manufacturing, precision and efficiency are paramount. One technological marvel that has revolutionized the industry is the endless diamond wire cutting machine. This cutting-edge innovation, often referred to as the “Ring of Diamond,” has played a pivotal role in the production of silicon wafers, enabling semiconductor manufacturers to achieve unparalleled precision and productivity. In this article, we delve into the world of silicon rod cutting and explore how endless diamond wire cutting machines have become indispensable in the semiconductor manufacturing process.

The Importance of Silicon Rod Cutting

Silicon wafers are the building blocks of the semiconductor industry. These thin, round discs of silicon are the foundation upon which microchips and electronic components are fabricated. Achieving precision and consistency in silicon wafer production is crucial, as even the slightest imperfection can lead to defects in electronic devices.

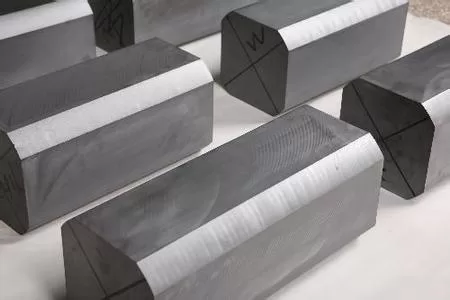

One critical step in silicon wafer production is silicon rod cutting. This process involves slicing large cylindrical silicon ingots into thin wafers with exceptional accuracy. Historically, traditional cutting methods presented various challenges, including slow production speeds, high material wastage, and the risk of contamination. However, the advent of endless diamond wire cutting machines has transformed the industry landscape.

Endless Diamond Wire Cutting Machine: A Game-Changer

Endless diamond wire cutting machines have emerged as a game-changer in the semiconductor manufacturing industry. These machines employ a continuous loop of diamond-coated wire to cut through silicon rods with unparalleled precision and efficiency. Here’s how they work:

1. Diamond Wire:

The cutting wire is coated with industrial-grade diamonds, making it extremely hard and durable. This ensures long-lasting performance and minimal wear.

2. Constant Tension:

The wire is maintained at a constant tension throughout the cutting process, ensuring uniform cuts and minimizing material wastage.

3. High-Speed Cutting:

Endless diamond wire cutting machines can operate at high speeds, significantly increasing production efficiency.

4. Reduced Contamination:

Unlike traditional methods that use abrasive materials, diamond wire cutting minimizes the risk of contamination, resulting in cleaner and more reliable silicon wafers.

Applications in Semiconductor Manufacturing

Endless diamond wire cutting machines find extensive applications in semiconductor manufacturing:

1. Silicon Rod Cutting:

Endless diamond wire cutting finds its niche in the semiconductor industry in the precise removal of the head and tail of silicon ingots or crystals. These regions typically contain impurities and irregular structures, making them less suitable for subsequent processes like wafering.

Benefits of Endless Diamond Wire Cutting

The adoption of endless diamond wire cutting machines offers several key benefits to semiconductor manufacturers:

1. Efficiency:

These machines can operate continuously, significantly increasing production efficiency and reducing labor costs.

2. Material Savings:

The minimal kerf width of the diamond wire results in less material wastage, contributing to cost savings.

3. Cleaner Cuts:

Diamond wire cutting produces cleaner, smoother cuts, reducing the need for post-processing and enhancing overall quality.

4. Environmental Impact:

Reduced material wastage and energy-efficient cutting processes make diamond wire cutting a more environmentally friendly option.

Conclusion

In the world of semiconductor manufacturing, precision is paramount, and endless diamond wire cutting machines have emerged as indispensable tools for achieving it. These machines offer unmatched precision, efficiency, and material savings, making them the preferred choice for silicon rod cutting and other critical processes in the industry.

As a leader in the field of endless diamond wire cutting machines, we are committed to providing cutting-edge solutions that empower semiconductor manufacturers to stay at the forefront of technology. If you are looking to enhance your semiconductor production processes, explore our range of products and services. Join the revolution and experience the future of precision silicon rod cutting with our endless diamond wire cutting machines. Contact us today to learn more.