Introducing our Free Cut Service:

Unlock the Potential of Endless Diamond Wire Cut Technology!

Discover the power of precision cutting with our innovative Endless Diamond Wire Cut technology. We understand that this cutting-edge solution might be new to many, leaving clients curious about its capabilities. That’s why we’re excited to offer our Free Cut Service.

How it Works:

Curious if your material can be flawlessly cut by our Endless Diamond Wire technology? Send us a sample, and our experts will perform a complimentary cut, showcasing the technology’s capabilities on your material. Experience firsthand the precision, efficiency, and quality our technology delivers.

Why Choose Our Free Cut Service:

🔍 Material Assessment: Unsure if your material is compatible? Our Free Cut Service provides clarity by demonstrating the technology’s effectiveness on your specific material.

⌛ Time and Cost Savings: Avoid potential time and financial investments by witnessing the technology’s performance before committing.

📈 Confidence in Quality: See the exceptional cut quality and edge finish achieved by our technology, instilling confidence in your project’s success.

🔬 Expert Insights: Our team of experts will provide insights into the cut process, helping you understand the technology’s potential applications.

Experience the future of cutting technology with our Free Cut Service. Empower your projects with precision, efficiency, and innovation. Contact us today to unlock the endless possibilities of Endless Diamond Wire Cut technology!

Cutting test cases that we have conducted for clients

to demonstrate the capabilities and effectiveness of our Endless Diamond Wire Cut technology:

- Semiconductor Materials: Conducted cutting tests on various semiconductor materials, showcasing the technology’s ability to achieve precise cuts on silicon ingot while maintaining minimal material loss and high accuracy.

- Glass Components: Showcased the technology’s precision in cutting glass components for optical instruments and electronics, highlighting its ability to deliver pristine edge quality without the need for extensive post-processing.

- Ceramic Substrates: Conducted cutting tests on ceramic substrates used in electronic components, illustrating the technology’s capacity to achieve high precision even on complex designs.

- Sapphire Crystal: Demonstrated precise cuts on sapphire crystal, essential in industries like watchmaking and electronics, showcasing accurate dimensions and a flawless finish.

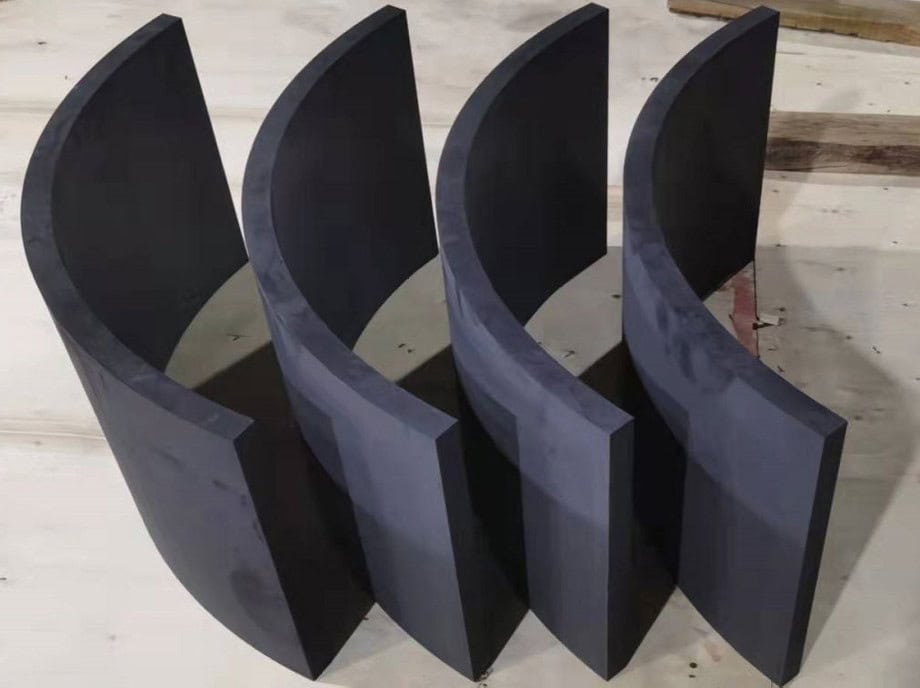

- Graphite Components: Conducted cutting tests on graphite material, meeting the strict quality requirements of the semiconductor industry and ensuring precision and reliability.

- Aerospace Materials: Showcased the technology’s effectiveness in cutting aerospace-grade materials such as titanium and composites, vital for precision components in aircraft and spacecraft.

- Jewelry Production: Demonstrated the precision of the technology in creating intricate designs on precious and semi-precious stones, enhancing the quality and intricacy of jewelry manufacturing.

- Corrugated Paper Cutting Test: We conducted a cutting test on corrugated paper, a material commonly used in cat scratching toy. The test showcased how our Endless Diamond Wire Cut technology can achieve precise and clean cuts on this material.

These cutting test cases showcase the versatility, accuracy, and efficiency of our Endless Diamond Wire Cut technology across a wide range of industries.

GET IN TOUCH

Schedule a Test Cut

Comprehensive Insights: We believe that informed decisions are empowered decisions. That’s why each cutting test is accompanied by comprehensive insights. Understand the technology’s performance, its potential applications, and how it can elevate your projects.

Partnering for Success: Our cutting test services are more than just tests; they’re a partnership for success. We’re committed to helping you make informed choices, ensuring that you harness the full potential of Endless Diamond Wire Cut technology for your projects.

Embark on a journey of discovery with our cutting tests. Witness precision, efficiency, and innovation in action. Contact us to tailor a cutting test that answers your questions, overcomes challenges, and paves the way for your project’s success.