When cutting materials, all saws are no longer created equal. Different tools are designed for exclusive works. Two saw blade types that could seem comparable but serve exceptional functions are the glass wire and the regular saw. Let’s dive into what makes them regular and whether you will use one over the opposite.

What is a Glass Wire Saw?

A glass wire saw is a specialized machine designed to cut glass and other sensitive materials. It uses a skinny wire covered with abrasive particles. This wire moves at a high speed to slice through the glass smoothly. The key here is precision. Glass is fragile, and it may easily crack or shatter if you use the incorrect tool. The glass wire saw’s layout prevents this by making easy, correct cuts.

What is a Regular Saw?

A regular saw is an extra standard tool you might locate in any toolbox. It regularly has a metallic blade with sharp teeth. These teeth are designed to cut through wood, plastic, or steel. There are many kinds of regular saws, like hand, round, and hacksaws. Each one has a selected reason. However, they all have the same primary characteristic—cutting through materials by transferring the blade back and forth.

Key Differences Between a Glass Wire Saw and a Regular Saw

Material and Purpose

The most significant difference between a glass wire and a regular saw is the cloth they are designed to cut. A glass wire saw is made especially for slicing glass, ceramics, and other brittle materials. On the other hand, a regular saw is supposed to cut more rigid materials like wood, steel, or plastic.

Cutting Technique

A glass wire saw uses a first-rate wire that cuts by grinding through the cloth. This procedure is slower, but a good deal more specific. It’s best for making intricate shapes or slicing fragile materials without breaking them. In contrast, a regular saw cuts by cutting through the fabric with a sharp tooth. This approach is faster, but much less specific, and no longer appropriate for delicate materials like glass.

Blade Design

The blade of a regular saw has a sharp tooth alongside the edge. These teeth grab and tear through the fabric, as you see. The glass wire saw, however, no longer has a tooth. Instead, it uses an easy wire with abrasive particles. This wire grinds through the cloth instead of tearing it, which is why it’s best for cutting glass.

Speed and Precision

When you want precision, the glass wire saw is your pleasant pal. It permits gradual, cautious cuts that decrease the risk of damage. However, it’s now not the quickest tool for slicing. A regular saw is preferred if you want to make short, rough cuts through timber or metallic. It’s rapid and efficient, but it sacrifices precision for pace.

Risk of Damage

Cutting glass with a regular saw is risky. The sharp enamel and pressure needed to reduce through more difficult materials can effortlessly cause glass to crack or shatter. A glass wire saw significantly reduces this danger. Its mild cutting approach guarantees that the glass remains intact, even during complex cuts.

What is the Best Glass Cutting Wire Saw Machine?

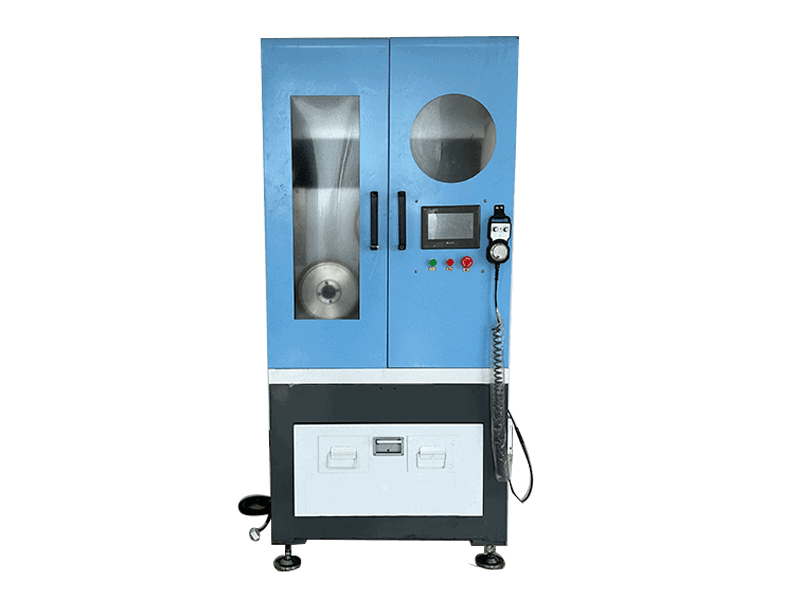

If you are looking for a great glass-cutting tool or glass saw machine, the SG 20 is a top contender. This machine sticks out due to its advanced generation and high precision. It’s designed to address complex cuts readily, making it ideal for unique glasswork. The SG 20 offers automated reduction, which saves time and ensures regular outcomes.

Where to Buy the Best Glass Cutting Wire Saw Machine?

Finding a dependable supplier is critical when buying a first-rate glass-cutting wire saw machine for precision glass cutting. For top-exceptional machines, you should don’t forget “Shine.” They are recognized for his or her great products and incredible customer service. Shine gives a wide range of wire saw for glass machines, perfect for both novices and experts. Whether you want a system for intricate glass designs or business-level cutting, Shine has the suitable alternative.

FAQs

Can I use a regular saw to reduce glass?

No, it’s no longer recommended. A regular saw’s sharp enamel can cause the glass to crack or shatter. A glass wire saw is the higher preference for cutting glass.

What materials can a glass wire saw cut?

A glass wire saw can cut glass, ceramics, skinny stones, and other fragile materials. It’s designed for precision and lowering the threat of damage.

Is a glass wire saw slower than a regular saw?

Yes, a tumbler wire saw is generally slower as it focuses on precision in preference to velocity. However, it’s the more secure desire for sensitive materials.

Final Words

The primary difference between a glass wire saw and a regular saw lies in the materials they’re designed to reduce and the way they perform. A glass wire saw is perfect for delicate, specific paintings with fragile materials, whilst a regular saw is ideal for more difficult, faster slicing obligations. Knowing which machine to use can prevent time and effort and save you luxurious errors.