A graphite wire saw might sound like a complex tool, but it’s truly quite captivating. This special device has loads of blessings, specifically if you work with substances like semiconductors, ceramics, or even gems. In this article, we can discover what a graphite wire saw is and what the advantages of using one are.

What Is a Graphite Wire Saw?

A graphite or wire saw technology is a reducing device that uses a thin wire made from graphite to slice through hard materials. The wire is covered with tiny, sharp diamonds, making it very powerful for precision slicing. People regularly use Công cụ cắt chính xác in industries like electronics, manufacturing, and jewelry because they want to cut tough and sensitive materials with excessive accuracy.

The Advantages of Using a Graphite Wire Saw

1: High Precision Cutting

One of the most important benefits of using graphite wire is its capacity to reduce with high precision. Graphite wire is your quality buddy when you want to minimize materials into skinny slices or specific shapes. This device lets you make clean, sharp cuts without destroying the fabric.

2: Reduced Material Waste

Another terrific advantage of a graphite wire saw is that it reduces material waste. Traditional reducing equipment may be challenging, leading to cracks or chips in the cloth. But with a graphite wire saw, you get a clean cut, which means less waste. This is particularly crucial while working with costly materials like silicon or gemstones.

3: Cooler Cutting Process

Heat is not an unusual trouble when reducing hard materials. Too much warmth can harm the fabric or the cutting tool. However, graphite wire was seen to produce much less warmness at some stage when slicing. This more relaxed slicing procedure is more secure and helps hold the material’s quality.

4: Versatility in Material Cutting

Graphite wire saws are versatile. They can reduce many materials, such as metals, ceramics, silicon, and gemstones. This versatility makes the graphite wire saw a treasured tool in many specific industries.

5: Smooth Surface Finish

After reducing with a graphite wire, the cloth typically has a clean surface. This smooth finish means you regularly don’t need much additional polishing or grinding. This is a massive gain for industries where appearance and smoothness are essential, like ring-making or semiconductor production.

6: Longer Tool Life

Graphite wire saws generally have an extended lifespan compared to different reducing gears. This is because they may be designed to address tough materials without wearing down quickly. The diamond wire saw coating on the wire allows it to live sharper, which means you don’t need to replace the device as regularly.

7: Cleaner Working Environment

When you use a hard material cutting, the slicing method produces less dust and debris than other reducing gear. This results in cleaner working surroundings, which are higher in your fitness and less challenging to keep. A cleaner workspace also has way less time spent cleaning up after a job, permitting you to add extra to your paintings.

What Is the Best Graphite Wire Saw?

These wire saws are recognized for his or her excellent overall performance and reliability in reducing harsh substances.

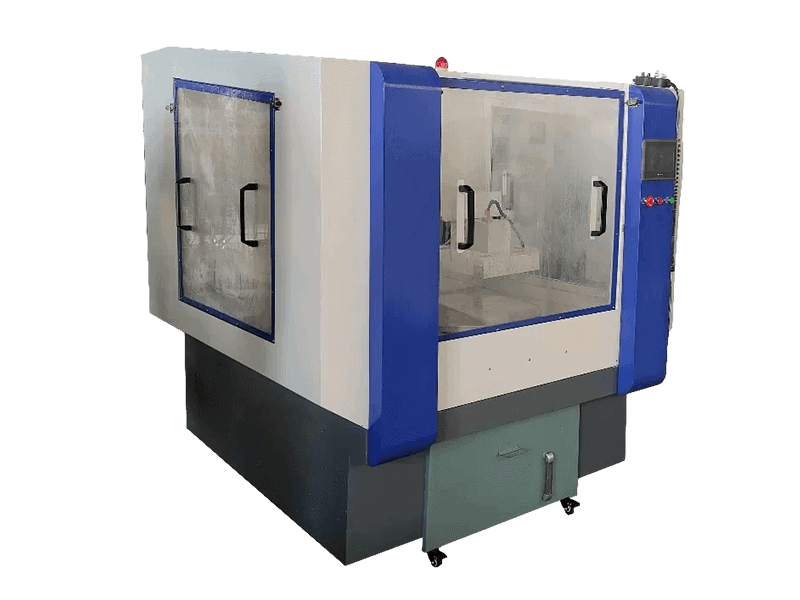

1: SH 60-60

The SH 60-60 is a top-notch graphite wire saw that excels in precision reduction. It’s designed to address a diffusion of materials, making it a versatile choice for one-of-a-kind industries. The SH 60-60 appears distinctly for its durability and capacity to supply smooth, accurate cuts. This device is perfect for people who need regular results without compromising excellence.

2: SHG250-130

Another fantastic option is the SHG250-a hundred thirty. This graphite wire is known for its advanced slicing pace and efficiency. It’s specifically valuable for environments wherein time and precision are vital. The SHG250-130 is a superior generation that reduces material waste and ensures a cleaner cut.

Where to Buy the Best Graphite Wire Saw Machine?

If you’re looking to buy an excellent máy cắt than chì hoặc cưa dây công nghiệp, you should consider shopping for it from Shine. Shine is a well-known dealer that specializes in super-reducing tools, including the SH 60-60 and SHG250-130 models.

“Shine” offers quite several graphite wire saw machines, which are ideal for diverse industries. Whether you’re in electronics, production, or any other area that requires particular cutting, Shine has the proper tool for you.

Câu hỏi thường gặp

What materials can a graphite wire saw reduce?

Graphite wire can cut a variety of materials, including metals, ceramics, silicon, and gemstones. Its versatility makes it beneficial in many unique industries.

How does a graphite wire saw reduce fabric waste?

The precision and smooth slicing of graphite wire reduced the possibilities of cracking or chipping the fabric, leading to much less waste and resource savings.

Is a graphite wire saw secure to apply?

Yes, a graphite wire saw is safe to use. It produces less heat during cutting, reducing the chance of harm to the cloth and making the technique safer on average.

Lời kết

A graphite wire saw is a powerful tool that offers many advantages. It provides high precision, reduces material waste, and operates with a more relaxed cutting process. Its versatility allows it to cut a wide range of materials, while the smooth surface finish and longer tool life add even more value.