In the world of high-tech manufacturing, precision and efficiency are paramount. This is especially true when it comes to cutting optoelectronic materials, which are integral to a myriad of modern technologies. Enter the wire saw machine, a game-changer that has transformed the landscape of optoelectronic material processing. This article delves into the revolutionary role of wire saw machines, particularly those offered by Shine, in cutting optoelectronic materials, highlighting their significance in various industries and the technological advancements they bring.

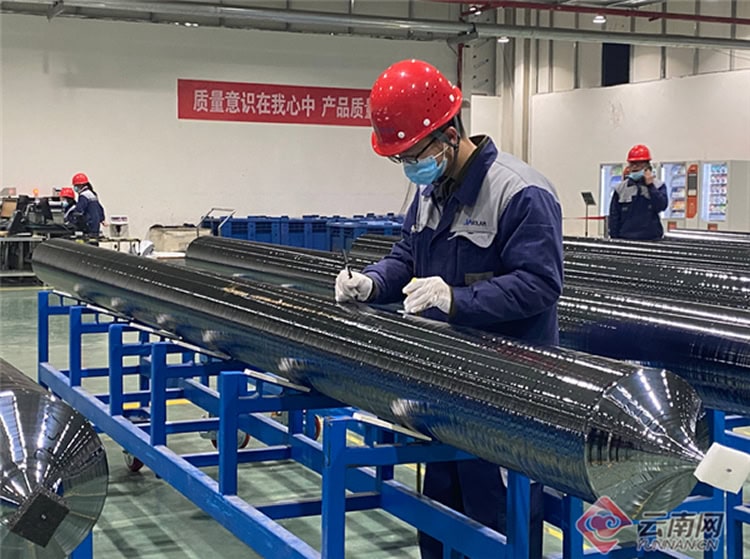

Wire saw machines have revolutionized the way we cut and shape optoelectronic materials, offering precision and efficiency that were previously unattainable. Imagine trying to carve a delicate sculpture with a blunt knife; it’s nearly impossible without causing damage. Similarly, before the advent of wire saw machines, cutting optoelectronic materials like silicon wafers, sapphire, and other crystals was a daunting task. These machines, especially the diamond wire saw machines, use ultra-thin wires embedded with diamond particles to slice through materials with surgical precision, minimizing waste and maximizing output.

The benefits of using wire saw machines, such as those produced by Shine, are numerous and impactful. Here are some key advantages:

- Reduced Material Wastage: Traditional cutting methods often result in significant material loss. Wire saw machines, particularly Máy cắt dây kim cương, minimize wastage by making thinner cuts.

- Enhanced Cutting Accuracy: Precision is crucial when working with optoelectronic materials. Wire saw machines offer unparalleled accuracy, ensuring that each cut is exact and consistent.

- Delicate Handling: Optoelectronic materials can be fragile. Wire saw machines are designed to handle these materials gently, reducing the risk of damage during the cutting process.

- Tính linh hoạt: These machines can cut a wide range of materials, from silicon to sapphire, making them indispensable in various industries.

The versatility of wire saw machines extends to numerous applications within the optoelectronic industry. Here are some areas where these machines make a significant impact:

- LED Manufacturing: The production of LEDs requires precise cutting of semiconductor materials. Wire saw machines ensure that each component is cut to perfection, enhancing the performance and longevity of the LEDs.

- Solar Panels: Creating solar panels involves slicing silicon wafers with high precision. Wire cutting machines, especially diamond wire saw machines, are crucial in achieving the desired thickness and smoothness.

- Advanced Communication Devices: From smartphones to fiber optics, optoelectronic components are integral. Wire saw machines enable the creation of intricate parts necessary for these advanced technologies.

As technology continues to evolve, so do wire saw machines. Companies like Shine are at the forefront of these advancements, incorporating cutting-edge features into their machines. For instance, the latest diamond wire cutting machines are equipped with automated systems that enhance precision and efficiency. These innovations promise even greater accuracy, reduced cutting times, and lower operational costs.

Looking ahead, the future of wire saw machines in the optoelectronic industry is bright. With ongoing research and development, we can expect even more sophisticated machines that push the boundaries of what’s possible. Imagine a future where cutting optoelectronic materials is as easy as slicing through butter – that’s the potential we’re looking at.

Despite their numerous advantages, wire saw machines do face certain challenges. Maintenance and cost are two significant hurdles. Regular maintenance is essential to ensure optimal performance, but it can be time-consuming and expensive. Additionally, the initial investment in high-quality wire saw machines can be steep.

However, solutions are available. For instance, Shine offers comprehensive maintenance packages that include regular check-ups and prompt repairs, ensuring that their machines operate at peak efficiency. Moreover, the long-term benefits of using wire saw machines – such as reduced wastage, enhanced precision, and increased productivity – often outweigh the initial costs, making them a worthwhile investment for any optoelectronic manufacturer.

In conclusion, wire saw machines are revolutionizing the way we cut and shape optoelectronic materials. With their precision, efficiency, and versatility, these machines are unlocking new possibilities in various industries. As technology continues to advance, the future of wire saw machines, particularly those from Shine, looks incredibly promising, paving the way for even greater innovations in the optoelectronic sector.

Introduction to Wire Saw Machines

Wire saw machines have revolutionized the way we cut and shape optoelectronic materials, offering precision and efficiency that were previously unattainable. These machines, particularly the diamond wire cutting machines, have become indispensable in various industries due to their ability to handle delicate and intricate materials with minimal wastage. The brand Shine has been at the forefront of this technological advancement, providing state-of-the-art wire cutting machines that cater to the ever-evolving needs of the optoelectronic sector.

But what makes these machines so special? Imagine trying to slice through a delicate piece of cake with a blunt knife—it would crumble and lose its shape. Similarly, cutting optoelectronic materials requires a tool that can make precise, clean cuts without causing damage. This is where wire saw machines, especially diamond wire saw machines, come into play. They use a thin wire coated with diamond particles to slice through materials like butter, ensuring smooth and accurate cuts every time.

The introduction of wire saw machines has brought about a paradigm shift in the manufacturing processes of optoelectronic components. These machines offer several advantages, including:

- Enhanced precision and accuracy in cutting

- Reduced material wastage

- Ability to handle delicate materials without causing damage

- Increased efficiency and productivity

Shine’s wire cutting machines are designed to meet the highest standards of quality and performance, making them a preferred choice for industries that rely on optoelectronic materials. Whether it’s for cutting LEDs, solar panels, or advanced communication devices, Shine’s diamond wire cutting machines deliver unparalleled results.

In conclusion, the advent of wire saw machines has opened up new possibilities in the world of optoelectronics. With their precision, efficiency, and ability to handle delicate materials, these machines have become an essential tool for manufacturers looking to push the boundaries of innovation. And with brands like Shine leading the way, the future looks brighter than ever.

Advantages of Using Wire Saw Machines

Wire saw machines, particularly those from Shine, have truly revolutionized the landscape of cutting optoelectronic materials. These machines offer a multitude of benefits that make them indispensable in various industries. Let’s delve into some of the standout advantages.

Firstly, wire saw machines are renowned for their precision and accuracy. When dealing with optoelectronic materials, even the slightest error can lead to significant losses. Shine’s wire cutting machines ensure that each cut is made with meticulous accuracy, reducing the margin for error to almost zero. This precision is especially crucial when working with delicate materials that are integral to the functionality of LEDs, solar panels, and advanced communication devices.

Another significant advantage is the reduction in material wastage. Traditional cutting methods often result in substantial material loss, which can be costly and inefficient. However, Shine’s diamond wire cutting machines minimize this wastage, ensuring that more of the raw material is utilized effectively. This not only saves costs but also promotes sustainability by reducing the amount of discarded material.

Moreover, wire saw machines are exceptionally versatile. They can handle a wide range of materials, from the most delicate to the most robust. This versatility is particularly beneficial in the optoelectronic industry, where materials can vary significantly in their properties. Shine’s diamond wire saw machines are designed to adapt to these variations, providing a reliable solution for different cutting needs.

One of the most impressive features of wire saw machines is their ability to maintain the integrity of the materials being cut. Traditional cutting methods can often cause damage or micro-cracks, compromising the material’s performance. However, Shine’s wire cutting machines ensure that the structural integrity of the optoelectronic materials is preserved, which is crucial for their functionality and longevity.

In addition to these benefits, wire saw machines also offer enhanced efficiency and speed. The cutting process is not only faster but also more consistent, leading to higher productivity. This efficiency is a game-changer in industries where time is of the essence, allowing for quicker turnaround times without sacrificing quality.

To summarize, the advantages of using wire saw machines, especially those from Shine, include:

- Exceptional precision and accuracy

- Significant reduction in material wastage

- High versatility in handling various materials

- Preservation of material integrity

- Enhanced efficiency and speed

These benefits make wire saw machines an invaluable asset in the optoelectronic industry and beyond. As technology continues to advance, we can expect these machines to become even more efficient and versatile, further solidifying their role in modern manufacturing processes.

Applications in the Optoelectronic Industry

The optoelectronic industry is a dynamic field where precision and efficiency are paramount. The introduction of wire saw machines, particularly diamond wire saw machines, has revolutionized various applications within this sector. Shine, a leading name in the industry, has been at the forefront of this transformation, providing state-of-the-art wire cutting machines that cater to a wide range of optoelectronic applications.

One of the most significant applications of wire saw machines in the optoelectronic industry is in the manufacturing of LEDs (Light Emitting Diodes). These tiny yet powerful light sources require precise cutting to ensure optimal performance and longevity. Wire cutting machines, especially diamond wire cutting machines, offer the precision needed to cut delicate LED materials without causing damage or wastage.

Another critical application is in the production of solar panels. Solar cells, which are the heart of solar panels, need to be cut with extreme accuracy to maximize their efficiency. Shine’s diamond wire saw machines excel in this area, providing clean and precise cuts that enhance the overall performance of solar panels. This not only improves the energy output but also reduces material wastage, making the production process more sustainable.

In addition to LEDs and solar panels, wire saw machines play a crucial role in the creation of advanced communication devices. These devices often require intricate components that can only be achieved through precise cutting techniques. Wire cutting machines, with their ability to handle delicate materials, are perfect for this task. Shine’s wire cutting machines ensure that each component is cut to perfection, contributing to the overall quality and reliability of communication devices.

Let’s not forget the role of wire saw machines in the production of optoelectronic sensors. These sensors are used in a variety of applications, from medical devices to industrial automation. The precision offered by diamond wire saw machines ensures that each sensor is cut accurately, enhancing its performance and reliability. Shine’s innovative wire cutting solutions have made it possible to produce high-quality optoelectronic sensors that meet the stringent demands of various industries.

To summarize, the applications of wire saw machines in the optoelectronic industry are vast and varied. Here are some of the key applications:

- Manufacturing of LEDs

- Production of solar panels

- Creation of advanced communication devices

- Production of optoelectronic sensors

Shine’s wire cutting machines, including diamond wire cutting machines and diamond wire saw machines, have become indispensable tools in the optoelectronic industry. Their precision, efficiency, and ability to handle delicate materials make them the perfect choice for a wide range of applications. As technology continues to advance, we can expect even more innovative uses for these versatile machines, further cementing their importance in the optoelectronic sector.

Technological Innovations and Future Prospects

When it comes to the cutting-edge world of optoelectronics, the role of wire saw machines cannot be overstated. As technology continues to advance at a rapid pace, the innovations in wire saw machines, particularly diamond wire cutting machines and diamond wire saw machines, are paving the way for unprecedented precision and efficiency. These technological marvels are not just tools; they are the catalysts for the next big leap in optoelectronic manufacturing.

One of the most significant advancements in this field is the integration of Hệ thống điều khiển tự động in wire cutting machines. Automation allows for real-time adjustments and monitoring, ensuring that each cut is as precise as possible. Imagine a world where the margin of error is virtually zero—thanks to these advancements, that world is becoming a reality.

Another groundbreaking innovation is the use of vật liệu tiên tiến for the wires themselves. Diamond wire cutting machines, for instance, utilize diamond-embedded wires that offer unparalleled durability and cutting efficiency. This not only reduces the wear and tear on the machine but also ensures a cleaner, more precise cut. The brand Shine has been at the forefront of this innovation, continually pushing the boundaries of what’s possible.

Moreover, the future prospects for wire saw machines are incredibly promising. Here are some key areas where we can expect significant advancements:

- Độ chính xác được nâng cao: Future models will likely incorporate even more sophisticated sensors and AI algorithms to further minimize errors and enhance cutting accuracy.

- Energy Efficiency: As sustainability becomes a global priority, wire saw machines are being designed to consume less energy while maintaining high performance.

- Tính linh hoạt: The next generation of wire cutting machines will be capable of handling a wider range of materials, making them even more indispensable in various industries.

- Cost-Effectiveness: Technological advancements will drive down the cost of these machines, making them more accessible to smaller manufacturers and startups.

However, it’s not all smooth sailing. Despite these exciting advancements, wire saw machines face several challenges. Maintenance remains a significant issue, as the intricate components require regular upkeep to function optimally. Additionally, the initial cost of these advanced machines can be prohibitive for some. But don’t worry, solutions are on the horizon!

Innovative companies like Shine are already working on self-maintaining systems that can diagnose and fix minor issues autonomously, reducing downtime and maintenance costs. Additionally, as the technology becomes more widespread, economies of scale will naturally drive down prices, making these machines more affordable.

In conclusion, the technological innovations in wire saw machines, especially diamond wire cutting machines and diamond wire saw machines, are set to revolutionize the optoelectronic industry. With brands like Shine leading the charge, the future looks incredibly bright. As we continue to push the boundaries of what’s possible, one thing is clear: the best is yet to come.

Challenges and Solutions in Wire Cutting

While wire saw machines have indeed revolutionized the cutting of optoelectronic materials, they are not without their challenges. One of the primary issues faced by operators is the maintenance of these sophisticated machines. Regular upkeep is essential to ensure the diamond wire cutting machine operates at peak efficiency. However, the maintenance process can be both time-consuming and costly.

Another significant challenge is the initial cost of acquiring a high-quality wire cutting machine. Brands like Shine have developed advanced diamond wire saw machines, but these come with a hefty price tag. For smaller businesses or startups, the investment can be daunting. However, the long-term benefits, such as reduced material wastage and enhanced precision, often justify the initial expenditure.

Material compatibility is yet another hurdle. Not all optoelectronic materials respond the same way to cutting. Some are more brittle and prone to cracking, while others may require specific cutting speeds and techniques. The diamond wire saw machine must be versatile enough to handle a range of materials without compromising on quality.

To address these challenges, several solutions have been proposed and implemented. For maintenance issues, Shine has introduced automated diagnostic systems that monitor the machine’s health and alert operators to potential problems before they escalate. This proactive approach reduces downtime and extends the machine’s lifespan.

Financially, leasing options and installment plans can make acquiring a diamond wire cutting machine more accessible. Shine offers flexible payment plans that allow businesses to spread the cost over time, making it easier to manage the financial burden.

When it comes to material compatibility, ongoing research and development are crucial. Shine is continuously innovating to improve the adaptability of their wire saw machines. By incorporating advanced sensors and adaptive cutting algorithms, these machines can automatically adjust to the specific requirements of different materials, ensuring optimal performance.

In summary, while the challenges in wire cutting are significant, they are not insurmountable. Through a combination of advanced technology, proactive maintenance, and flexible financial solutions, companies like Shine are paving the way for a more efficient and effective future in the optoelectronic industry.

Câu hỏi thường gặp

- What are wire saw machines?Wire saw machines are advanced cutting tools used to slice through various materials with high precision. They employ a thin wire coated with abrasive particles to achieve clean and accurate cuts, especially in delicate optoelectronic materials.

- How do wire saw machines benefit the optoelectronic industry?Wire saw machines offer numerous benefits to the optoelectronic industry, including reduced material wastage, enhanced cutting accuracy, and the ability to handle delicate materials without causing damage. This precision is crucial for manufacturing high-quality LEDs, solar panels, and communication devices.

- What types of materials can be cut with wire saw machines?Wire saw machines are versatile and can cut a wide range of materials, including silicon, sapphire, ceramics, and other optoelectronic substrates. Their ability to handle both hard and brittle materials makes them indispensable in various industrial applications.

- Are there any challenges associated with using wire saw machines?Yes, despite their many advantages, wire saw machines do face challenges such as maintenance requirements and operational costs. These machines need regular upkeep to ensure optimal performance, and the initial investment can be significant. However, the long-term benefits often outweigh these hurdles.

- What are the latest technological advancements in wire saw machines?Recent technological advancements in wire saw machines include improvements in wire materials, cutting speeds, and automation. These innovations enhance precision and efficiency, paving the way for even more sophisticated applications in the optoelectronic sector.

- How do wire saw machines reduce material wastage?Wire saw machines reduce material wastage by making extremely thin cuts, which minimizes the amount of material lost during the cutting process. This precision ensures that more of the raw material is used effectively, leading to cost savings and increased efficiency.

- Can wire saw machines be used for large-scale production?Absolutely! Wire saw machines are capable of handling large-scale production thanks to their precision and efficiency. They are widely used in industries that require mass production of optoelectronic components, such as the solar panel and LED manufacturing sectors.

- What maintenance is required for wire saw machines?Regular maintenance for wire saw machines includes checking and replacing the wire, ensuring the abrasive particles are effective, and keeping the machine clean and well-lubricated. Proper maintenance is essential to maintain cutting accuracy and prolong the machine’s lifespan.

- How do wire saw machines compare to other cutting methods?Wire saw machines offer superior precision and less material wastage compared to traditional cutting methods like diamond saws or laser cutting. They are particularly advantageous for cutting delicate optoelectronic materials, where traditional methods might cause damage or excessive material loss.

- What is the future outlook for wire saw machines in the optoelectronic industry?The future outlook for wire saw machines in the optoelectronic industry is very promising. Ongoing technological advancements will likely lead to even greater precision and efficiency, enabling the development of new and innovative optoelectronic devices. As the demand for high-quality, precise components grows, wire saw machines will continue to play a crucial role.