Wire-cutting machines, such as the Wire EDM machine (Electrical Discharge Machining), are extensively used across diverse industries for particular and elaborate reducing obligations. These machines use a skinny wire to cut through substances, creating complicated shapes and designs with high accuracy. They are essential for industries that require the best detailing and easy finishes on harsh substances. In this text, we will discover the industries that depend on precision cutting machines and why those machines are so treasured.

Top Industries Use Wire Cut Machines

Aerospace Industry

The aerospace industry is one of the primary customers of electrical discharge machining. Aerospace additives frequently require severe precision because of the high standards for safety and performance. Parts like turbine blades, engine additives, and airframe elements are crafted from harsh substances like titanium and nickel alloys. Wire-cut machines can easily cut through these materials without adversely affecting them, ensuring the components meet the precise specs for secure and green plane operation.

Medical Industry

The Medical Industry is also primarily based on wire-reduction machines. Precision is essential for producing surgical equipment, implants, and scientific gadgets in this discipline. Materials like stainless steel, titanium, and specialized alloys are used to make the merchandise. CNC wire-cut machines ensure that those substances are cut with the maximum accuracy, which is vital for accomplishing surgical procedures and scientific methods.

Automotive Industry

Wire-slicing machines produce a wide variety of additives in the car industry. These machines are especially useful for growing additives requiring complicated shapes, including gears, engine additives, and transmission parts. Automobiles have many transferring elements, and wire-slicing machines make certain those additives are synthetic with vital precision for nice, ordinary overall performance.

Metal cutting technology’s ability to work with difficult metals like steel and aluminum makes it ideal for the auto industry. Car engines, for instance, ought to withstand high temperatures and pressure, and the parts should fit together flawlessly to function properly.

Electronics Industry

The electronics industry uses wire-reduce machines to fabricate sensitive additives like circuit boards, connectors, and microchips. These additives are frequently crafted from substances like copper, gold, and silicon, which require careful handling to prevent harm. Wire-cut machines offer precision in slicing those substances without affecting their overall performance.

Tool and Die Industry

The device and die industry uses high-precision machining to create molds, dies, and tooling elements. These gadgets are utilized in manufacturing approaches at some point in numerous industries, from plastic injection molding to metallic stamping. Wire reducing machines permit manufacturers to create complicated shapes with excessive accuracy, ensuring that the tools and dies fit their reason perfectly.

Defense Industry

The defense industry requires precision elements for weapons, vehicles, and communication systems. Wire-cut machines fabricate components like gun barrels, missile parts, and radar structures. These components ought to meet strict requirements for safety and reliability, and wire-cut machines ensure that they’re produced to precise specifications.

Jewelry Industry

Wire-cutting machines are also used within the ring industry to create complex designs in valuable metals like gold, silver, and platinum. Jewelers use wire EDM to create delicate styles, shapes, and gemstone settings. The precision of wire-cutting machines permits jewelers to produce incredibly unique pieces that can be stunning and purposeful.

What are the Best Wire Cut Machines?

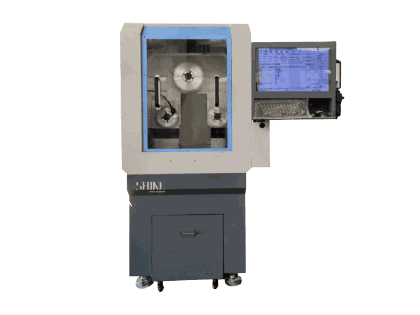

Two models stand out when selecting the high-quality wire cut machine: the SGSM 40 and the SH60-R. These Industrial wire cutting are designed for high-precision slicing, making them ideal for industries that require accuracy. The SGSM forty is thought for its efficiency and clean-reducing potential, making it a popular choice for professionals. The SH60-R offers advanced features, including improved speed and precision, making it a pinnacle performer for complex responsibilities. Both machines are manufactured using Shine, ensuring top-notch satisfaction and performance.

Where Can I Buy a Wire Cut Machine?

If you’re searching for a wire cut gadget, picking out a dependable supplier is essential. Shine Smart Equipment industry is one of the pleasant suppliers in the market. Known for its terrific machines, Shine gives wire-cutting machines that supply precision and durability. Their machines suit aerospace, medical, and automobile industries, where accuracy is crucial. Shine has first-rate recognition for presenting excellent customer support, making it a relied-on supplier for purchasing wire-cutting machines. Shine can meet your wishes with a reliable system whether you’re a small industry or a large producer.

FAQs

What is a wire cutting machine?

A wire-cutting gadget called a wire EDM device uses a skinny wire to cut materials with high precision. It often creates intricate shapes and easy finishes on complex substances like metal, titanium, and copper.

What industries use wire cut machines?

Wire-cut machines are used in many industries, including aerospace, scientific, automotive, electronics, device and die, defense, and jewelry. They offer the precision needed to create elements with exact specs.

Why is precision necessary in wire cut machines?

Precision is necessary because it ensures that elements in shape work effectively and characteristically well together. Even a tiny mistake can lead to failure in industries like aerospace and medical, so wire-cut machines provide the accuracy needed to avoid such troubles.

In Wrap Up

Wire cut machines are essential in many industries requiring high precision and accuracy. From aerospace to jewelry, these machines provide the potential to cut complicated shapes and offer smooth finishes on hard materials. They are particularly critical in fields in which safety and reliability are crucial, together with the clinical and protection industries. Producers can use wire-cut machines to ensure their products meet strict standards and function flawlessly. Whether slicing complicated medical gear or developing complex automotive parts, wire cutting machines offer the precision wished for achievement throughout various industries.