Table of Contents

An automatic wire cutting machine refers to an advanced type of cutting equipment that uses a wire embedded with diamond particles as the cutting tool, and it operates automatically. This machine combines the precision and effectiveness of diamond cutting with automation technology. Here’s a more detailed overview:

- Diamond Wire as Cutting Tool: The key feature of these machines is the use of a diamond-impregnated wire. Diamonds, being the hardest naturally occurring material, allow the wire to cut through a wide range of materials, including stone, concrete, metal, and semiconductor materials.

- Automated Operation: These machines are designed to operate automatically. Users can program specific dimensions and parameters into the machine’s control system. Once set up, the machine can carry out the cutting process with minimal human intervention, ensuring consistent results and high efficiency.

- Precision Cutting: Automatic wire cutting machines are known for their ability to make precise cuts. This is particularly important for applications requiring intricate shapes or where material wastage needs to be minimized.

- Versatility: They can handle various materials, making them suitable for industries like construction (for cutting stone and concrete), semiconductor manufacturing (for slicing silicon wafers), and metalworking.

- Speed and Efficiency: These machines can operate at high speeds, significantly increasing productivity. The automated process reduces the time and labor typically required for cutting operations.

- Safety and Reliability: Equipped with safety features to protect operators, these machines also provide consistent, reliable performance, which is essential in industrial settings where precision and repeatable results are crucial.

- Applications: Automatic wire cutting machines have a wide range of applications. In construction, they are used for cutting large stone blocks or concrete. In manufacturing, they are essential for slicing through hard materials like quartz, silicon, and various metals.

Types of Automatic Wire Cutting Machine

The diversity of Automatic wire cutting equipment offers tailored solutions for every need.

1. Multi Wire Structure: Maximizing Productivity

- Efficiency Redefined: With multiple wires working simultaneously, this setup dramatically increases productivity, making it an indispensable asset for large-scale operations.

2. Single Wire Structure: Precision Meets Versatility

- Endless Diamond Wire Type: Embrace the future with this innovative design. Its continuous loop of diamond-embedded wire means fewer interruptions and consistent quality. It’s not just a tool; it’s a game-changer for precision cutting.

- Diamond Wire on Spool Type: For traditionalists who value versatility, this type offers adaptability without sacrificing the quality of cuts.

Advantages of Diamond Wire Cutting – Why Settle for Less?

- Precision Cutting: If you’re looking for cuts that are both precise and clean, Automatic wire cutting is the only answer.

- Versatility: This technology is a one-size-fits-all solution, capable of handling various materials with ease.

- Efficiency: Especially with the endless diamond wire, the efficiency of your cutting process will skyrocket, saving time and reducing costs.

Comparing Diamond Wire Saws and Diamond Band Saws

Comparing Diamond Wire Saws and Diamond Band Saws involves looking at their design, operation, and typical applications. Both are powerful tools used for cutting hard materials, but they have distinct characteristics suited for different purposes.

Diamond Wire Saws

- Design and Operation:

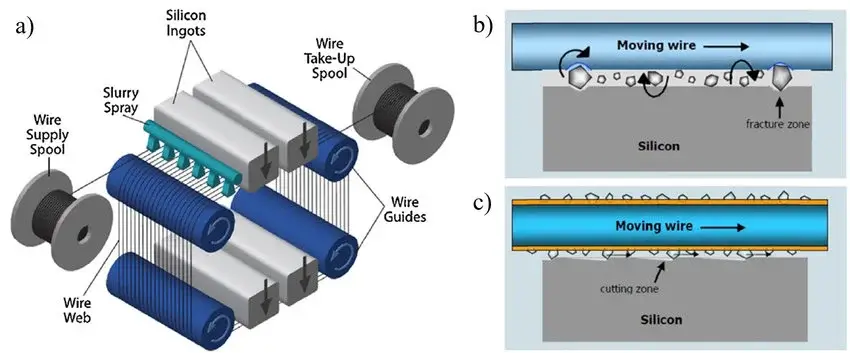

- A diamond wire saw uses a wire impregnated with diamond particles as the cutting tool.

- The wire is typically looped through a series of pulleys and continuously moves as it cuts.

- The wire can be of considerable length, allowing for large-scale and deep cuts.

- Applications:

- Ideal for cutting large blocks of stone, such as in quarrying.

- Used in the construction industry for cutting through thick concrete structures.

- In the semiconductor industry, for slicing through silicon wafers or other hard materials.

- Advantages:

- Can cut very large and thick materials.

- Capable of making intricate cuts and complex shapes.

- Minimal material waste due to the thin cutting wire.

- Limitations:

- Generally slower than band saws for small, straightforward cuts.

- Setup and operation can be more complex.

Diamond Band Saws

- Design and Operation:

- A diamond band saw utilizes a continuous band blade embedded with diamonds.

- The band is stretched over wheels, and it moves in a uniform direction, cutting material as it passes through.

- Typically used for smaller scale cuts compared to wire saws.

- Applications:

- Common in workshops for cutting shapes out of hard materials like glass, ceramic, and smaller stone pieces.

- Used in laboratories and manufacturing for cutting delicate materials that require precision.

- Advantages:

- Faster for small-scale operations.

- Generally easier to set up and operate.

- More suitable for detailed and precision work on a smaller scale.

- Limitations:

- Not as effective for very large or thick materials.

- The width of the cut (kerf) is generally wider than a wire saw, leading to more material waste.

Conclusion

- Choice Depends on Application: Diamond wire saws are more suited for large-scale, heavy-duty cutting tasks such as quarrying and large construction projects. Diamond band saws, on the other hand, are ideal for smaller, more detailed work in workshops and manufacturing settings where precision is key.

- Material Considerations: The choice also depends on the material type and the size of the material to be cut. For very large stone blocks or thick concrete, wire saws are preferable, whereas for intricate designs in glass, ceramics, or small stone pieces, band saws are better suited.

- Cost and Efficiency: Consideration should also be given to the cost, both of the initial investment and ongoing operations, as well as the efficiency needed for the specific cutting tasks.

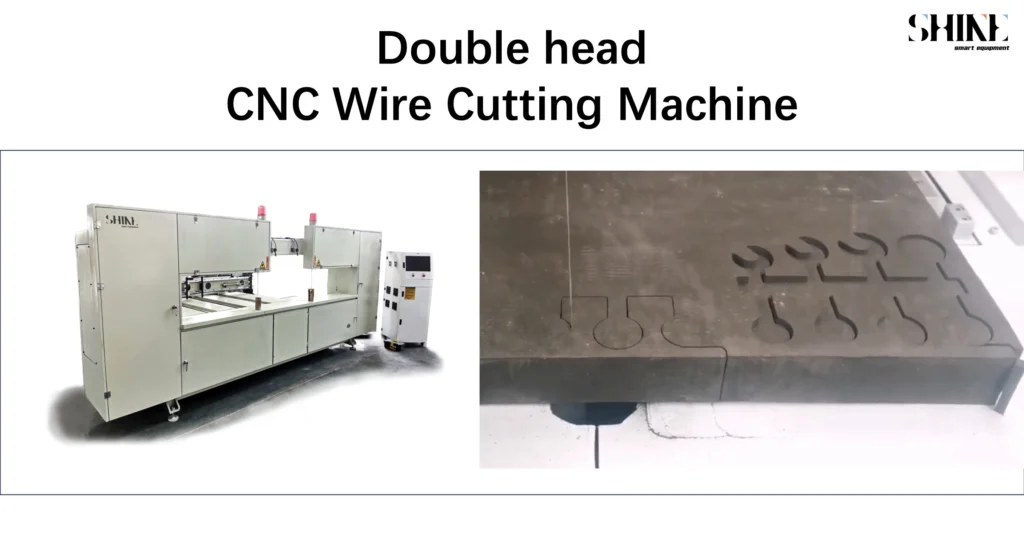

In summary, automatic wire cutting machine is a diamond wire saw with CNC programed programe.