Keywords: Wire Cut Machinery,Cut Machinery

Table of Contents

Introduction to Wire Cut Machinery

Wire cut machinery, an indispensable tool in modern manufacturing, has revolutionized the way we shape and design materials. This innovative technology allows for precision cutting of various materials, ranging from metals to ceramics, using a thin wire as the cutting tool. The wire, often made from materials like brass or coated with substances like diamond, acts as a saw, slicing through the material with remarkable accuracy and minimal waste.

The significance of wire cut machinery lies in its ability to produce intricate shapes and patterns that would otherwise be impossible or economically unfeasible with traditional cutting methods. Its application spans across numerous industries, including aerospace, electronics, and automotive, where precision is paramount. The versatility and efficiency of wire cut machinery make it a preferred choice for complex and detailed manufacturing processes.

In this article, we delve into the world of wire cut machinery, exploring its basic principles, historical development, and the advanced technology behind endless diamond wire cut machinery. We also discuss its various applications and the latest advancements in the field, providing valuable insights for industry professionals and enthusiasts alike.

Basic Principles of Wire Cut Machinery

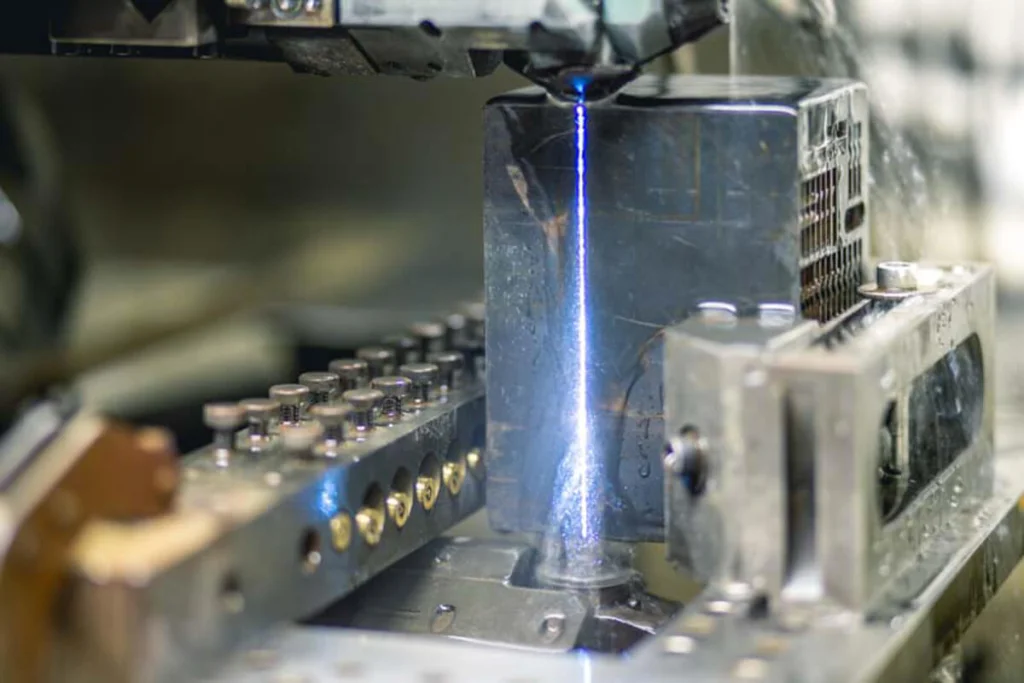

Wire cut machinery operates on a simple yet ingenious principle. It uses a thin wire, typically made from brass or coated with materials like diamond, as a cutting tool. This wire is continuously fed from a spool through the workpiece, controlled by a sophisticated set of motors and CNC (Computer Numerical Control) systems. The cutting process is usually performed in a deionized water bath, which serves both as a coolant and as an electrical insulator.

The key to the cutting process is the use of electrical discharge machining (EDM). Here, the wire is charged to a specific voltage, creating an electrical spark between the wire and the workpiece. This spark produces intense heat, which melts or vaporizes a tiny portion of the material, thereby cutting it. The process is highly precise, allowing for complex cuts with tolerances in the micrometer range.

Different types of wire cut machinery are designed to handle various materials and thicknesses. The choice of wire material and coating also plays a crucial role. For instance, diamond-coated wires are renowned for their durability and cutting efficiency, particularly in slicing through hard materials like quartz, silicon, and ceramics.

The ability to perform intricate and precise cuts without exerting mechanical force on the workpiece makes wire cut machinery an invaluable asset in manufacturing contexts where material integrity and accuracy are critical.

Historical Development of Wire Cut Machinery

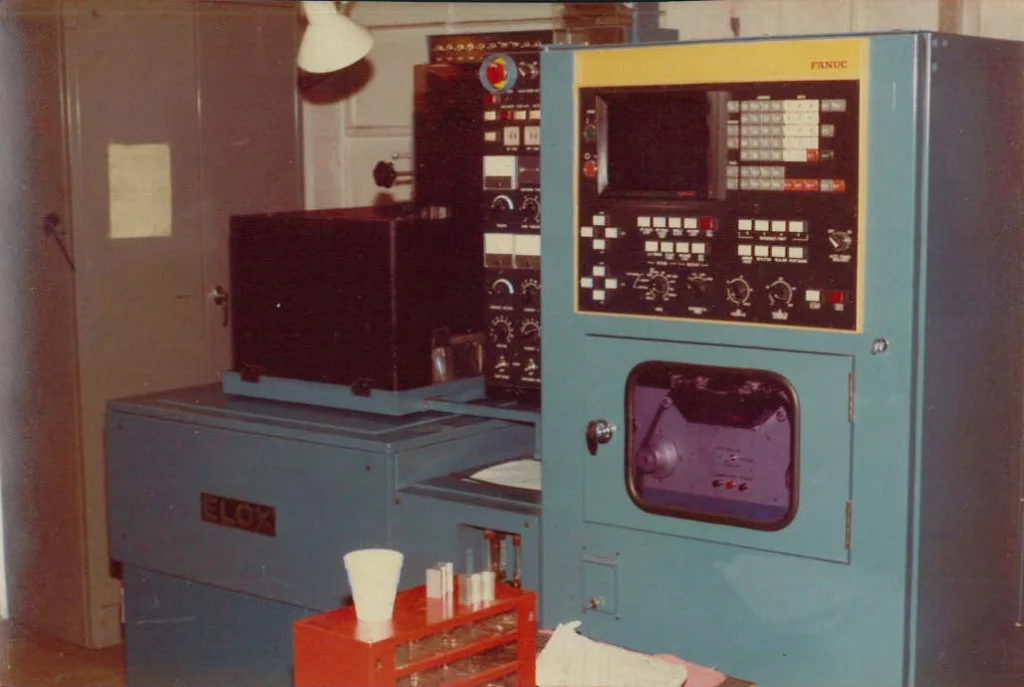

The evolution of wire cut machinery is a testament to the advancements in manufacturing technology. The inception of this technology dates back to the 1960s, with the development of Electrical Discharge Machining (EDM). Initially, EDM was used for removing hardened steel, but it soon expanded into other applications as the technology matured.

The breakthrough came with the introduction of the continuous wire EDM in the 1970s. This innovation allowed for a continuous wire feed, significantly increasing efficiency and precision. It opened new possibilities in manufacturing, enabling the production of more complex and delicate parts.

Throughout the 1980s and 1990s, the technology underwent rapid improvements. Advancements in CNC technology and the development of better electrical insulation materials led to enhanced precision and speed. The machines became more user-friendly, with improved control systems and software, making them accessible to a wider range of industries.

The introduction of diamond-coated wires marked another significant milestone. These wires, known for their hardness and durability, allowed for the cutting of extremely hard materials, further expanding the capabilities of wire cut machinery.

The historical journey of wire cut machinery reflects a constant pursuit of precision, efficiency, and versatility. From its humble beginnings to its current status as a cornerstone in modern manufacturing, the trajectory of this technology showcases an ever-evolving landscape of innovation and engineering excellence.

The Technology Behind Endless Diamond Wire Cut Machinery

Endless diamond wire cut machinery represents a pinnacle in the evolution of wire cut technology. This advanced system uses a loop of wire coated with diamond particles, the hardest material known, which enables it to cut through almost any material, including silicon, quartz, and even sapphire.

The “endless” aspect of the wire is crucial. Unlike traditional wire EDM where the wire is continually fed from a spool and discarded after use, the endless diamond wire is looped, allowing for continuous and uninterrupted cutting. This design not only reduces waste but also increases cutting efficiency and speed.

The diamond coating on the wire provides unmatched cutting abilities. Diamonds, being incredibly hard, can produce a much finer cut with higher precision than traditional wires. This is especially valuable in industries where material integrity and precision are paramount, such as in semiconductor manufacturing and precision engineering.

The machinery also incorporates advanced tension control systems to maintain optimal wire tension, ensuring consistent cutting performance. This, combined with state-of-the-art CNC systems, allows for extremely intricate and complex cutting patterns, all while maintaining high levels of accuracy and efficiency.

Endless diamond wire cut machinery is a prime example of how continuous innovation in wire cut technology has led to more sustainable, efficient, and precise manufacturing solutions.

Applications in Various Industries

Wire cut machinery, particularly those utilizing endless diamond wires, has found applications in a diverse range of industries, underscoring its versatility and efficiency.

1. Semiconductor Industry

- In the semiconductor industry, precision is critical. Endless diamond wire cut machinery is used for slicing silicon wafers, a foundational component of integrated circuits. The precision of these machines ensures minimal material wastage and maintains the integrity of the silicon, which is crucial for the functionality of the semiconductor devices.

2. Aerospace and Aviation

- The aerospace and aviation industries rely on parts with exact specifications. Wire cut machinery is used to shape components made of superalloys and other high-strength materials, essential for the safety and performance of aircraft.

3. Medical Device Manufacturing

- In medical device manufacturing, wire cut machinery is used to produce intricate components like stents and other implantable devices. The ability to work with biocompatible materials and achieve high precision is vital in this field.

4. Automotive Industry

- The automotive industry uses wire cut machinery for creating detailed parts, such as gears and other precision components. The technology’s ability to handle various materials and maintain high accuracy is highly valued.

5. Jewelry and Fine Art

- The precision of wire cut machinery, especially those with diamond wires, is also exploited in jewelry making and fine art. It allows artists and designers to create intricate designs in hard materials like gemstones.

Each industry benefits from the specific advantages of wire cut machinery: precision, material versatility, and efficiency. The integration of such technology not only enhances manufacturing capabilities but also drives innovation in product design and functionality.

Advances in Wire Cut Machinery Technology

The field of wire cut machinery has seen significant technological advancements in recent years, each pushing the boundaries of precision and efficiency.

1. Enhanced Precision and Speed

- Modern wire cut machines offer greater precision and faster cutting speeds than ever before. This is a result of improvements in CNC technology, which allow for more precise control over the cutting process. The use of advanced algorithms and AI in controlling the cutting patterns has also contributed to this enhanced capability.

2. Improved Wire Materials and Coatings

- The development of new wire materials and coatings has been pivotal. The introduction of wires with nano-crystalline diamond coatings, for instance, has further increased the cutting efficiency and lifespan of the wire, especially when working with hard materials.

3. Automation and Smart Features

- Automation and smart features are becoming increasingly common. These include automatic wire tensioning, real-time monitoring systems, and predictive maintenance capabilities. Such features not only improve the efficiency of the cutting process but also reduce the downtime and maintenance costs.

4. Sustainable Practices

- Sustainability is becoming a focus area, with the industry moving towards more eco-friendly practices. This includes recycling used wires and optimizing cutting processes to minimize waste.

5. Future Trends

- Looking ahead, the integration of more advanced AI and machine learning algorithms is expected to further enhance the precision and capabilities of wire cut machinery. There is also a growing trend towards the customization of machines to cater to specific industry needs.

Choosing the Right Wire Cut Machinery

Selecting the appropriate wire cut machinery is crucial for achieving desired manufacturing outcomes. Here are key factors to consider when making this decision:

1. Material and Thickness of the Workpiece

- The type and thickness of the material to be cut play a crucial role in selecting the right machine. Different machines are optimized for different materials and thicknesses, and choosing the appropriate one ensures optimal cutting efficiency and precision.

2. Precision Requirements

- The required precision level is a vital consideration. Industries like semiconductor manufacturing or aerospace demand extremely high precision. Machines with advanced control systems and finer wires, such as those with diamond coatings, are better suited for such applications.

3. Cutting Speed and Efficiency

- The desired cutting speed is also an important factor. Higher cutting speeds can increase production throughput but may impact precision and surface finish. Balancing speed with quality needs is essential.

4. Machine Features and Capabilities

- Features such as automatic wire tensioning, advanced CNC controls, and real-time monitoring systems enhance the usability and efficiency of the machine. Depending on the complexity of the tasks, these features can significantly impact productivity.

5. Operational and Maintenance Costs

- Considering the operational and maintenance costs is important for long-term sustainability. Machines with higher durability, efficient use of consumables, and lower maintenance requirements might have a higher upfront cost but prove more economical in the long run.

6. Manufacturer and Support Services

- Finally, the reputation of the manufacturer and the availability of support services are crucial. Reliable customer support, availability of spare parts, and technical assistance can greatly impact the machine’s operational lifespan and effectiveness.

Selecting the right wire cut machinery involves a careful assessment of these factors, ensuring that the chosen equipment meets the specific needs of the operation.