Have you ever found yourself staring at a tangled mess of wires, desperately seeking the precision cuts required for your manufacturing projects? If so, you’re not alone. The journey to mastering wire cutting can be fraught with challenges, leaving even the most seasoned manufacturers feeling perplexed and frustrated. From selecting the right equipment to honing the necessary skills, navigating the world of wire cutting machines can feel like an uphill battle. It’s a struggle that we, at SHINE, understand all too well.

In this guide, we extend our hand to offer guidance and support to those grappling with the complexities of wire cutting. Through our comprehensive exploration of Wire Cutting Machine Manufacturers, we aim to shed light on the intricacies of the industry and provide practical solutions to common challenges. Whether you’re a newcomer seeking direction or an experienced professional in search of optimization, our goal is to serve as your trusted companion on this journey towards wire cutting mastery. Join us as we delve into the heart of wire cutting technology, unraveling its mysteries one wire at a time.

Table of Contents

Whether you’re looking to optimize your wire cutting processes, explore new techniques, or stay ahead of emerging trends, our guide has you covered. So, if you’re ready to unlock your full potential and elevate your wire cutting skills, dive into our guide and let us be your trusted companion on the road to mastery.

Wire Cutting Machine Manufacturers: Revolutionizing Precision Cutting

Introduction

Wire cutting machines are the unsung heroes of modern manufacturing, revolutionizing the way materials are cut with unparalleled precision and efficiency. In industries ranging from automotive to aerospace, these machines play a crucial role in shaping the products we rely on every day. In this comprehensive guide, we will delve into the world of wire cutting machine manufacturers, exploring the types of machines available, key factors to consider when choosing one, top manufacturers in the industry, successful case studies, emerging trends, and much more.

Types of Wire Cutting Machines

CNC Wire EDM Machines

CNC Wire EDM (Electrical Discharge Machining) machines utilize electrical discharges to cut materials with extreme precision, making them ideal for intricate shapes and delicate materials.

Laser Wire Cutting Systems

Laser wire cutting systems harness the power of laser technology to achieve precise cuts on various materials, offering high-speed and accuracy.

Automatic Wire Straightening and Cutting Machines

Automatic wire straightening and cutting machines streamline the process of preparing wires for further fabrication, enhancing efficiency and reducing labor costs.

Factors to Consider When Choosing Wire Cutting Machines

Precision and Accuracy

The ability of a wire cutting machine to deliver precise and accurate cuts is paramount, especially in industries where tolerances are tight and quality is non-negotiable.

Cutting Capacity and Speed

Manufacturers must assess the cutting capacity and speed of a wire cutting machine to ensure it meets the demands of their production requirements.

Versatility and Compatibility

The versatility of a wire cutting machine, including its compatibility with different materials and geometries, determines its suitability for diverse applications.

Automation and Ease of Use

Automation features and user-friendly interfaces enhance the efficiency and usability of wire cutting machines, reducing setup time and operator errors.

Cost and Return on Investment

While upfront costs are important, manufacturers should also consider the long-term return on investment offered by a wire cutting machine in terms of productivity gains and reduced material waste.

Top Wire Cutting Machine Manufacturers

When it comes to wire cutting machine manufacturers, several companies stand out for their innovation, reliability, and performance. Let’s explore some of the leading players in the industry, including our very own SHINE company.

1. Precision Machinery Co.

- Overview: Precision Machinery Co. has been a trusted name in wire cutting technology for over three decades.

- Product Range: From precision CNC wire cutters to high-speed EDM wire cutting machines, Precision Machinery Co. offers a comprehensive range of solutions.

- Unique Selling Points: Renowned for their superior accuracy and durability, Precision Machinery Co.’s machines are favored by manufacturers worldwide.

2. Global Wire Tech

- Overview: Global Wire Tech is a global leader in wire cutting innovation, known for pushing the boundaries of technology.

- Product Range: Their product lineup includes advanced laser wire cutting systems and automated wire straightening and cutting machines.

- Unique Selling Points: Global Wire Tech’s machines are prized for their cutting-edge features, reliability, and exceptional performance.

3. CustomCut Solutions Inc.

- Overview: CustomCut Solutions Inc. specializes in providing customized wire cutting solutions tailored to specific customer needs.

- Product Range: From specialized wire bending machines to wire straightening and cutting systems, CustomCut Solutions Inc. offers a wide range of options.

- Unique Selling Points: With a focus on customization and flexibility, CustomCut Solutions Inc. delivers bespoke solutions that meet the unique requirements of their clients.

4. TechWire Innovations Ltd.

- Overview: TechWire Innovations Ltd. is dedicated to continuous innovation in wire cutting technology, driving advancements in precision and efficiency.

- Product Range: Their product portfolio includes state-of-the-art CNC wire EDM machines and diamond wire cutting systems.

- Unique Selling Points: TechWire Innovations Ltd. is known for its commitment to innovation and excellence, ensuring their machines deliver top-notch performance and reliability.

5. SHINE Manufacturing Co.(the best recommendation for you)

- Overview: SHINE Manufacturing Co. is a leading wire cutting machine manufacturer known for its dedication to quality and customer satisfaction.

- Product Range: From precision wire cutting machines to advanced diamond wire cutting systems, SHINE offers a wide range of solutions to meet diverse manufacturing needs.

- Unique Selling Points: With a focus on innovation and reliability, SHINE’s machines are designed to optimize production processes and exceed industry standards.

These top wire cutting machine manufacturers set the standard for excellence in the industry, each bringing unique strengths and innovations to the table. Whether you’re looking for precision, reliability, or customization, these companies offer cutting-edge solutions to meet your manufacturing needs.

Case Studies of Successful Implementations

Automotive Industry: Driving Innovation

In the automotive industry, wire cutting machines are instrumental in producing complex components with precision, contributing to the safety and performance of vehicles.

Aerospace Industry: Reaching New Heights

Aerospace manufacturers rely on wire cutting machines to fabricate critical components for aircraft, meeting stringent quality standards and performance requirements.

Electronics Industry: Powering Innovation

Wire cutting machines play a crucial role in the production of electronic devices, ensuring the accuracy and reliability of components such as circuit boards and connectors.

Construction Industry: Building the Future

In construction, wire cutting machines are used to cut reinforcement bars and structural materials with precision, enabling the construction of resilient and sustainable buildings.

Emerging Trends in Wire Cutting Machine Technology

Automation and Robotics Integration

The integration of automation and robotics enhances the efficiency and productivity of wire cutting processes, reducing reliance on manual labor and improving overall throughput.

Industry 4.0 and IoT Connectivity

Wire cutting machines are increasingly being connected to the Internet of Things (IoT), allowing for real-time monitoring, predictive maintenance, and data-driven optimization.

Advanced Materials and Composites Cutting

Advancements in materials science have led to the development of new alloys and composites, driving the need for wire cutting machines capable of handling these cutting-edge materials.

Sustainability and Eco-friendly Solutions

Manufacturers are exploring eco-friendly alternatives in wire cutting technology, such as water-based cutting methods and energy-efficient systems, to minimize environmental impact.

Considerations for Choosing a Wire Cutting Machine Manufacturer

When selecting a wire cutting machine manufacturer, several factors should be taken into consideration to ensure you make the right choice for your manufacturing needs. Here are some key considerations to keep in mind:

1. Quality and Reliability

- SHINE Tip: Ensure that the manufacturer has a reputation for producing high-quality and reliable machines.

- Look for certifications and industry awards that demonstrate the manufacturer’s commitment to quality.

2. Technology and Innovation

- SHINE Tip: Choose a manufacturer that stays abreast of the latest technological advancements in wire cutting.

- Consider manufacturers that offer innovative features such as advanced automation, precision controls, and integration with Industry 4.0 technologies.

3. Product Range and Customization Options

- SHINE Tip: Opt for a manufacturer that offers a diverse range of wire cutting machines to suit your specific needs.

- Look for customization options that allow you to tailor the machine to your unique requirements, such as different cutting capacities, wire diameters, and material compatibility.

4. Customer Support and Service

- SHINE Tip: Select a manufacturer that provides comprehensive customer support and after-sales service.

- Look for manufacturers that offer training programs, technical assistance, and prompt maintenance and repair services to keep your machines running smoothly.

5. Price and Value

- SHINE Tip: While price is important, consider the overall value offered by the manufacturer.

- Compare the upfront cost of the machine with factors such as durability, performance, and long-term reliability to determine the best value for your investment.

6. Industry Reputation and Reviews

- SHINE Tip: Research the manufacturer’s reputation within the industry and read customer reviews and testimonials.

- Look for manufacturers with positive feedback and a track record of satisfied customers to ensure a positive experience.

7. Compatibility and Integration

- SHINE Tip: Consider how the wire cutting machine integrates with your existing manufacturing processes and equipment.

- Choose a manufacturer that offers compatibility with other machinery and seamless integration into your production line.

8. Warranty and Guarantee

- SHINE Tip: Check the warranty and guarantee offered by the manufacturer to protect your investment.

- Look for manufacturers that provide generous warranty terms and guarantees of machine performance to provide peace of mind.

By considering these factors and conducting thorough research, you can choose the right wire cutting machine manufacturer to meet your manufacturing needs and drive success in your operations. Remember to explore the offerings of SHINE Manufacturing Co. for cutting-edge solutions and unparalleled reliability. Explore SHINE’s wire cutting machines for superior quality and performance.

Comparison of Wire Cutting Machine Models

Feature Comparison Chart

A detailed comparison chart highlighting the key features and specifications of various wire cutting machine models facilitates informed decision-making for manufacturers.

Performance Metrics Analysis

Analyzing performance metrics such as cutting speed, accuracy, and reliability helps manufacturers evaluate the overall effectiveness and efficiency of wire cutting machines.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Cutting Method | CNC Wire EDM | Laser Wire Cutting | Diamond Wire Cutting |

| Maximum Wire Diameter | 0.3 mm | 0.5 mm | 0.8 mm |

| Cutting Speed | 200 mm/min | 500 mm/min | 800 mm/min |

| Accuracy | ±0.005 mm | ±0.01 mm | ±0.005 mm |

| Material Compatibility | Metals, Alloys | Metals, Plastics | Hard and Brittle Materials |

| Customization Options | Limited | Moderate | Extensive |

| Automation Features | Basic | Advanced | Advanced |

| Integration with Industry 4.0 | No | Yes | Yes |

| Customer Support | Standard | Enhanced | Premium |

| Price | negotiate directly | negotiate directly | negotiate directly |

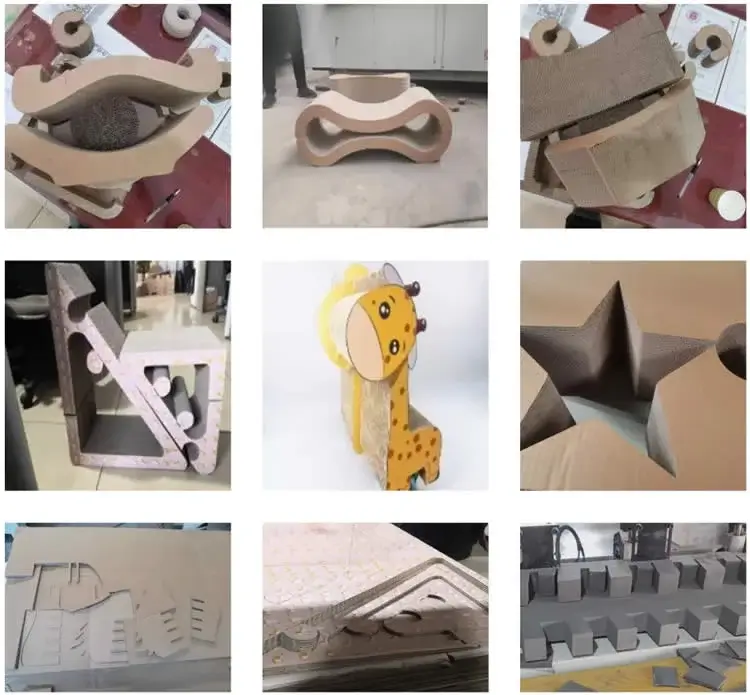

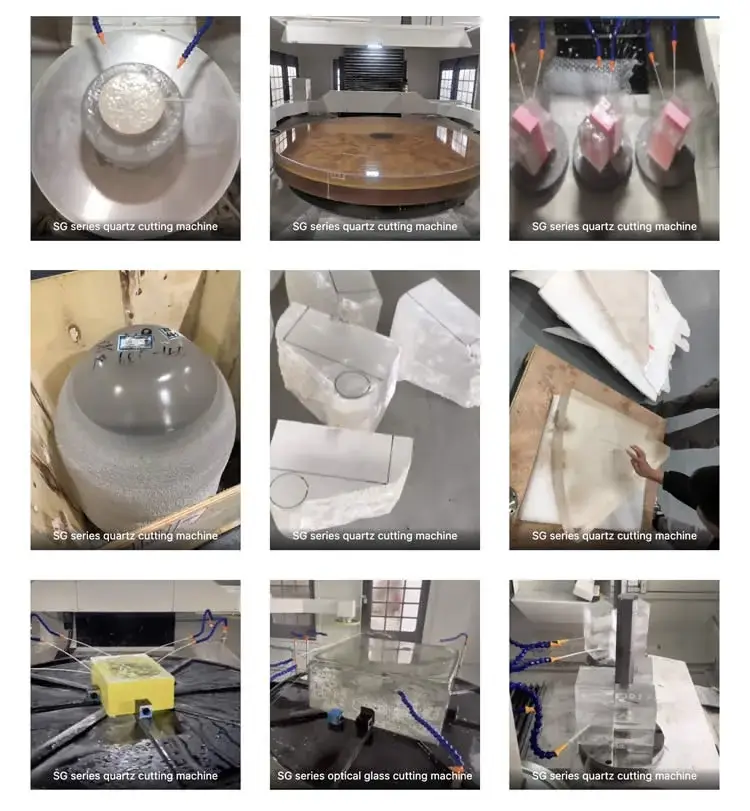

Enhance your wire cutting capabilities with our top-of-the-line Quartz Cutting Machinery. Discover precision cutting solutions and unlock new possibilities in your manufacturing processes. Upgrade your equipment today!

Recommended Product

Future Outlook and Market Projections

Growth Potential in Key Industries

The demand for wire cutting machines is expected to grow across industries such as automotive, aerospace, electronics, and construction, driven by advancements in technology and increasing demand for precision manufacturing.

Technological Advancements and Innovations

Future innovations in wire cutting machine technology are likely to focus on enhancing automation, improving precision, and expanding capabilities to meet evolving customer needs and industry requirements.

Conclusion

Wire cutting machines are indispensable tools in modern manufacturing, enabling precise and efficient cutting of materials across various industries. By understanding the different types of machines available, key factors to consider when choosing one, top manufacturers in the industry, successful case studies, emerging trends, and future outlook, manufacturers can make informed decisions to optimize their production processes and stay ahead of the competition.

FAQs (Frequently Asked Questions)

What are the primary applications of wire cutting machines?

Wire cutting machines are used in various industries for cutting materials such as metal, plastic, foam, and composites. They find applications in automotive, aerospace, electronics, and construction, among others.

How do wire cutting machines contribute to manufacturing efficiency?

Wire cutting machines enable manufacturers to achieve precise and consistent cuts, reducing material waste, improving productivity, and ensuring the quality of finished products.

What factors should be considered when selecting a wire cutting machine?

Key factors to consider include cutting capacity, precision, speed, versatility, ease of use, reliability, and cost-effectiveness.

How can manufacturers benefit from partnering with reputable wire cutting machine manufacturers?

Partnering with reputable manufacturers ensures access to high-quality machines, comprehensive technical support, and ongoing innovation, helping manufacturers stay competitive and meet evolving market demands.

What are some emerging trends in wire cutting machine technology?

Emerging trends include automation, integration with Industry 4.0 technologies, improved precision through advanced controls and sensors, and enhanced versatility to handle a wider range of materials and geometries.

In conclusion, when it comes to Wire Cutting Machine Manufacturers, SHINE stands out as a beacon of excellence, offering top-notch solutions tailored to your manufacturing needs. With our comprehensive guide and expert insights, we’ve equipped you with the knowledge and tools to navigate the world of wire cutting with confidence.

Now, it’s time to take the next step towards optimizing your manufacturing processes. Explore SHINE’s range of wire cutting machines and discover how our cutting-edge technology can elevate your production capabilities. Don’t let uncertainty hold you back – seize the opportunity to unlock your full potential with SHINE today.

For more in-depth tutorials and insights on wire cutting, don’t forget to check out our YouTube channel: Endless Diamond Wire Loop.